A kind of flexible wearable strain sensor and preparation method thereof

A strain sensor and wearable technology, applied in the field of flexible wearable strain sensor and its preparation, can solve the problems of unstable sensor function and short service life, achieve good mechanical adaptability, increase added value, and improve electrical conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The preparation method of the flexible wearable strain sensor of this embodiment comprises the following steps:

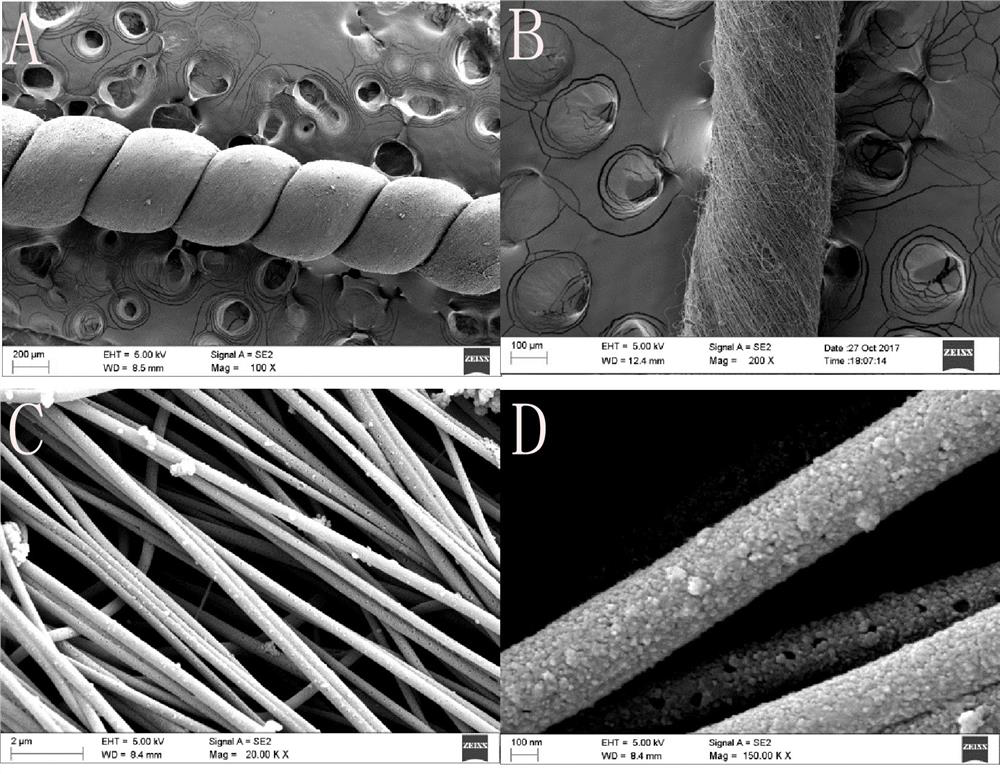

[0031] (1) Dissolve graphene oxide in dimethylformamide (DMF) solution, and perform strong ultrasonic treatment under sealed conditions to obtain a uniformly dispersed graphene oxide solution;

[0032] (2) Add dry polyacrylonitrile powder to the solution in step (1), stir at 80°C for 3 hours to obtain a spinning solution with a mass fraction of polyacrylonitrile of 10%, and the molecular weight of the polyacrylonitrile is 150000; the mass ratio of polyacrylonitrile to graphene oxide is 1:0.01;

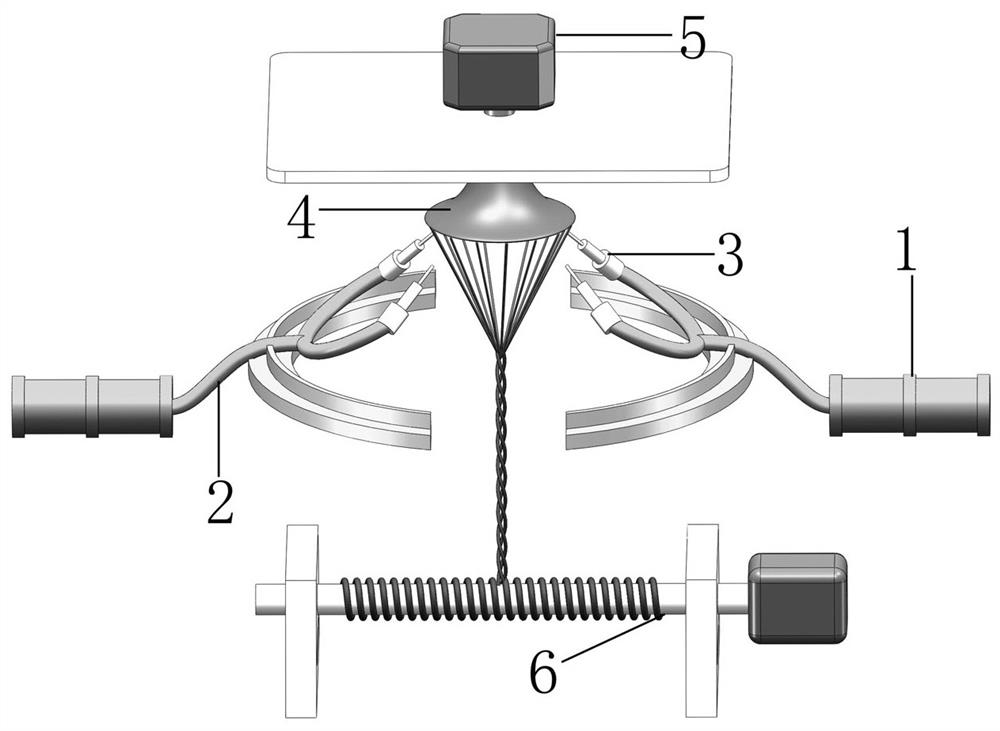

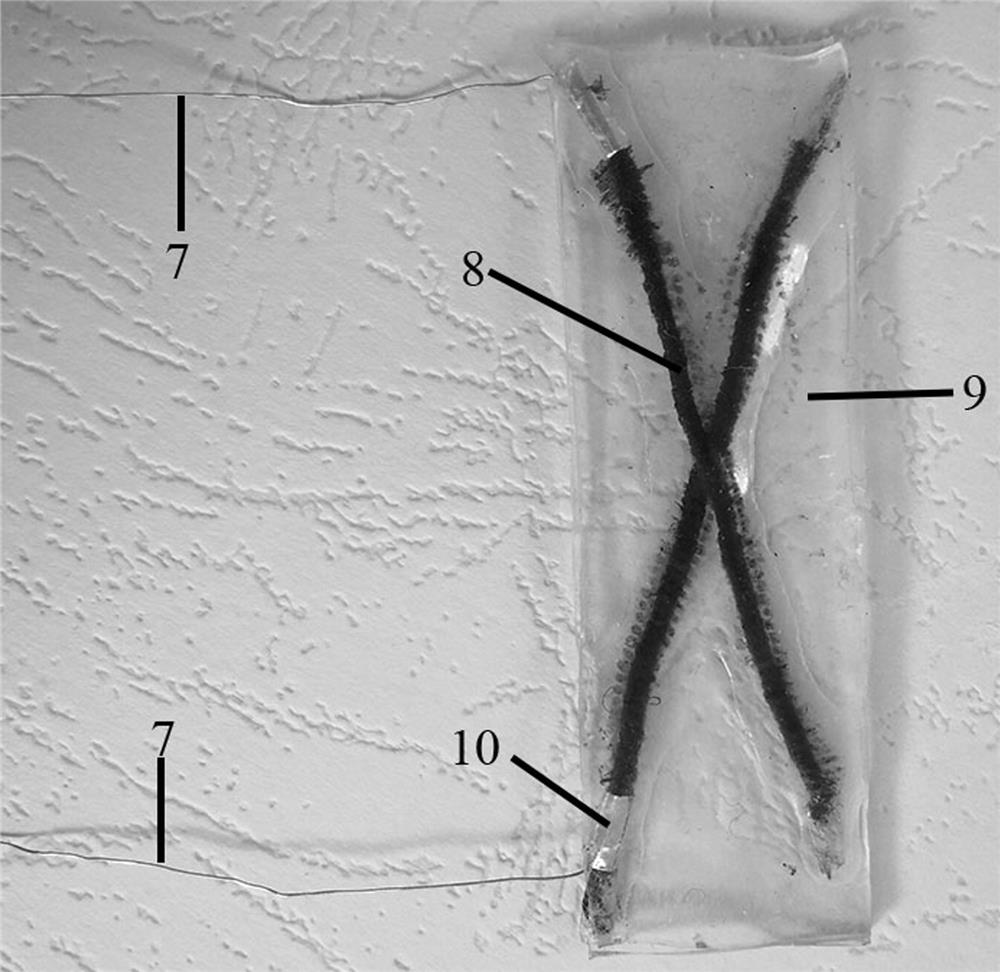

[0033] (3) Build the electrospinning device according to Figure 1, add the spinning solution in step (2) to the syringe pump to prepare continuous nanofiber yarn, the electrospinning voltage is 20 kV, and the total flow rate of the spinning solution is 0.8 mL / h, the distance between the positive and negative needles is 15 cm, the number of needles is 4, the solution...

Embodiment 2

[0040]The preparation method of the flexible wearable strain sensor of this embodiment comprises the following steps:

[0041] (1) Dissolve graphene oxide in dimethylformamide (DMF) solution, and perform strong ultrasonic treatment under sealed conditions to obtain a uniformly dispersed graphene oxide solution;

[0042] (2) Add dry polyacrylonitrile powder to the solution in step (1), stir at 50°C for 6 hours to obtain a spinning solution with a mass fraction of polyacrylonitrile of 8%, and the molecular weight of the polyacrylonitrile is 100000, the mass ratio of polyacrylonitrile to graphene oxide is 1:0.03;

[0043] (3) Build the electrospinning device according to Figure 1, add the spinning solution in step (2) to the syringe pump to prepare continuous nanofiber yarn, the electrospinning voltage is 17 kV, and the total flow rate of the spinning solution is 0.5 mL / h, the distance between the positive and negative needles is 17 cm, the number of needles is 4, the solution f...

Embodiment 3

[0049] The preparation method of the flexible wearable strain sensor of this embodiment comprises the following steps:

[0050] (1) Add the dry polyacrylonitrile powder into the dimethylformamide solution, stir at 60°C for 4 hours, and obtain a polyacrylonitrile solution with a mass fraction of 12% as the spinning solution. The polyacrylonitrile The molecular weight is 150000;

[0051] (2) Build the electrospinning device according to Figure 1, add the polyacrylonitrile solution in step (1) to the syringe pump to prepare continuous nanofiber yarn, the electrospinning voltage is 20 kV, and the total flow rate of the spinning solution is 0.8 mL / h, the distance between the positive and negative needles is 15 cm, the number of needles is 4, the positive and negative needle solution flow ratio is 1:0.7, the vertical distance between the needle and the edge of the bell mouth is 4 cm, and the winding speed is 35 mm / min;

[0052] (3) Soak the nanofiber yarn prepared in step (2) in fe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com