A method for improving core soil removal in tunnel double side wall pilot pit method construction

A technology of double-sided guide pit and core soil, which is applied in tunnels, earthwork drilling, mining equipment, etc., can solve the problems of shortened construction period, slow construction progress, and increased construction cost, so as to improve construction safety and construction efficiency. , the effect of shortening the construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033]In order to make the objectives, technical solutions and advantages of the present invention, the present invention will be further described in detail below with reference to the embodiments. It should be understood that the specific embodiments described herein are merely intended to illustrate the invention and are not intended to limit the invention.

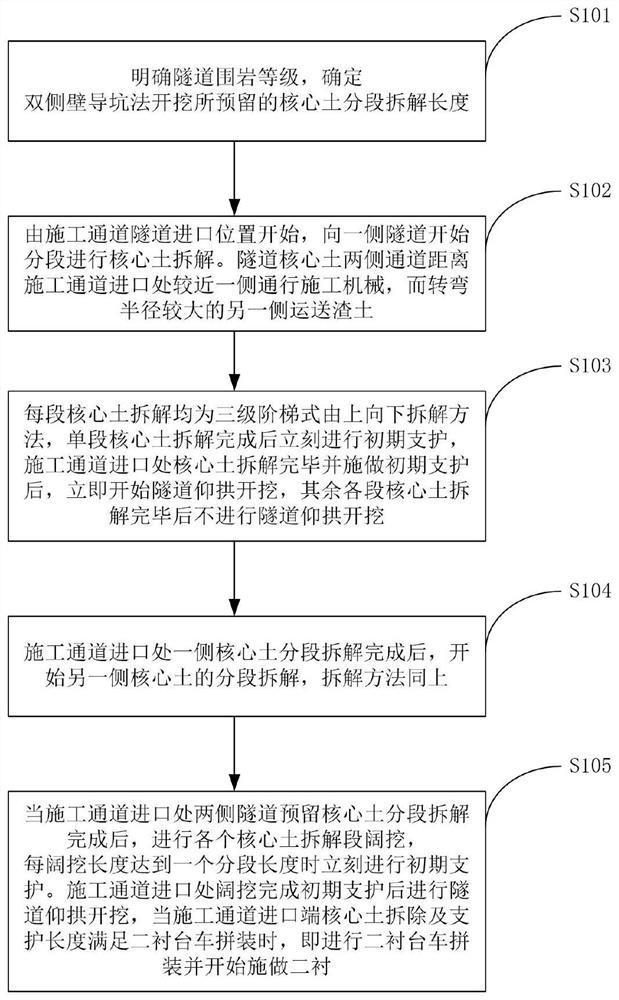

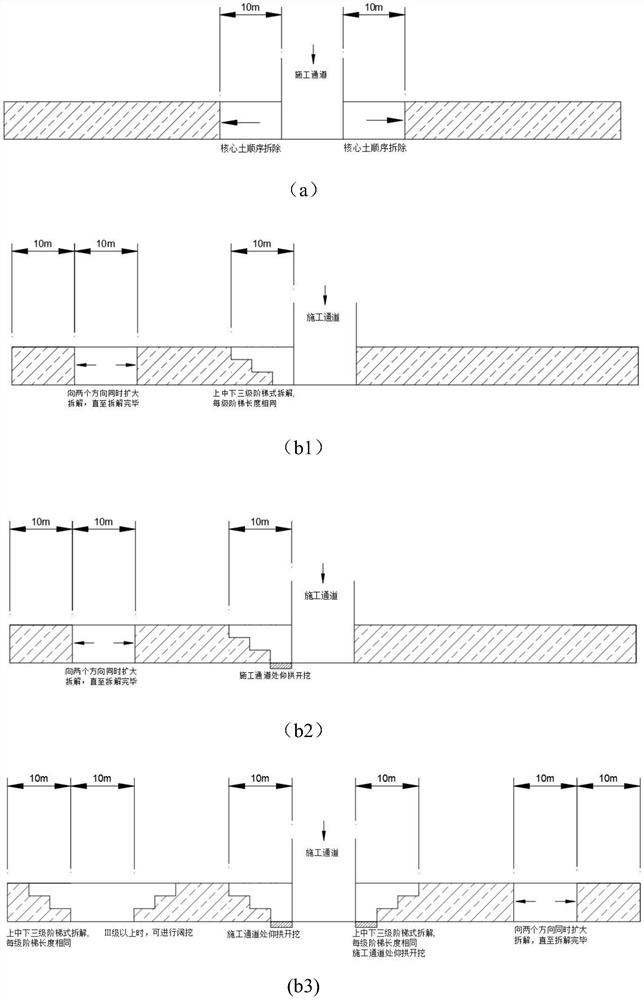

[0034]Such asfigure 1 As shown, the core soil release method for improving the bilateral wall of the tunnel bilateral wall is provided in the present invention includes the following steps:

[0035]S101: Clarify the tunnel surrounding rock level, determine the core soil segmentation length reserved by the double-sided wall guide pit method;

[0036]S102: Starting from the construction channel tunnel inlet position, the core earth solution is started to the side tunnel. The tunnel core soil is connected to the construction channel at the entrance of the construction channel, and the other side of the turning radius is larger transport...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com