A high-strength steel plate with a thickness of 8-25mm and a low yield ratio tank car and its manufacturing method

A technology with low yield ratio and manufacturing method, applied in the field of low alloy steel, can solve the problems of long production process, unfavorable mass production, high alloy cost, and achieve low production cost, excellent strength and toughness matching, and lower yield ratio. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The steel for the low-silicon universal joint ball cage and its manufacturing method described in the present invention will be further explained and described below in conjunction with the accompanying drawings and specific examples. However, the explanation and description do not constitute an improper limitation to the technical solution of the present invention. .

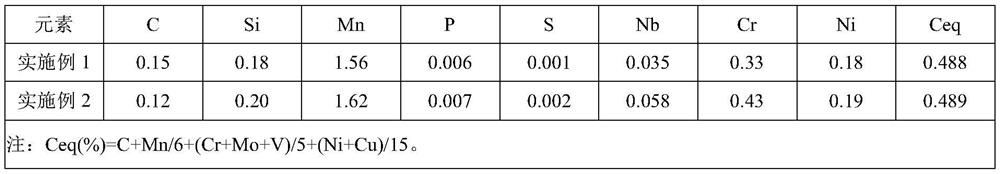

[0028] The smelting chemical composition of each embodiment of the present invention is shown in Table 1 (wt%), and the rest is Fe and unavoidable impurity elements.

[0029]Table 1

[0030]

[0031] The above-mentioned examples are all smelted in a 120-160t converter. The molten iron is desulfurized by KR, and the [S] reaches a minimum of 0.001%. Then, it is desulfurized, heated, refined and added with related alloys in the LF ladle furnace, and then desulfurized in the RH vacuum treatment furnace. Refining treatment such as degassing, removing inclusions, etc., fully remove inclusions and gases, en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com