A kind of preparation method of high-strength aluminum alloy bolt

An aluminum alloy, high-strength technology, used in manufacturing tools, heat treatment equipment, furnaces, etc., can solve problems such as backwardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

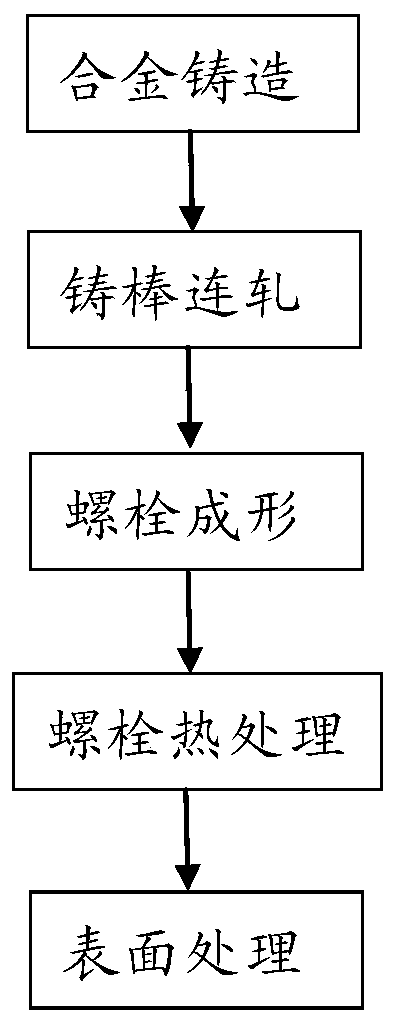

[0020] see figure 1 , a method for preparing a high-strength aluminum alloy bolt provided in an embodiment of the present invention includes the following steps:

[0021] Alloy casting: cast the aluminum alloy melt into a cast rod with a diameter of 60-100mm and a length of 10-27 meters through a semi-continuous casting process, control the segregation layer on the surface of the cast rod to be less than 3mm, and then homogenize the cast rod, and finally Cast rod milling, the thickness of the milling surface is 1-3mm, and the composition of the aluminum alloy melt is: Zn: 8.0-9.5wt.%, Mg: 1.7-2.9wt.%, Cu: 2.0-2.7wt. %, Zr: 0.08~0.2wt.%, Ti: 0.01~0.03wt.%, Si: <0.1wt.%, Fe: <0.15wt.%. Other unavoidable impurity elements are each less than 0.05wt.%, and the total is less than 0.15wt.%, and the balance is Al;

[0022] Cast rod continuous rolling: the cast rod is rolled into an aluminum rod with a diameter of 10-40mm by a short stress line continuous rolling mill, the rolling te...

Embodiment 1

[0036] Raw material preparation: alloy composition is Zn: 8.8wt.%, Mg: 2.6wt.%, Cu: 2.5wt.%, Zr: 0.15wt.%, Ti: 0.02wt.%, Si: <0.1wt.%, Fe : <0.15wt.%, other unavoidable impurity elements each less than 0.05wt.%, and the total is less than 0.15wt.%, the balance is Al. Use pure metal aluminum, pure metal zinc, pure metal copper, pure metal magnesium, Al-Zr master alloy, and Al-Ti master alloy as raw materials for material preparation.

[0037] Melting and casting: smelting in a reflective aluminum melting furnace, adding pure metal aluminum, Al-Zr master alloy, and Al-Ti master alloy to the furnace for melting at the same time, adding pure metal copper after melting, raising the temperature to 740°C, and adding pure metal Zinc, pure metal magnesium, when adding metal magnesium, press the magnesium block completely below the liquid surface through the pressure cover; after these metals are melted and stirred evenly, the temperature is raised to 750°C, and the refining agent is us...

Embodiment 2

[0045] Raw material preparation: alloy composition is Zn: 8.0wt.%, Mg: 2.3wt.%, Cu: 2.0wt.%, Zr: 0.08wt.%, Ti: 0.01wt.%, Si: <0.1wt.%, Fe : <0.15wt.%, other unavoidable impurity elements each less than 0.05wt.%, and the total is less than 0.15wt.%, the balance is Al. Use pure metal aluminum, pure metal zinc, pure metal copper, pure metal magnesium, Al-Zr master alloy, and Al-Ti master alloy as raw materials for material preparation.

[0046] Melting and casting: smelting in a reflective aluminum melting furnace, adding pure metal aluminum, Al-Zr master alloy, and Al-Ti master alloy to the furnace for melting at the same time, adding pure metal copper after melting, raising the temperature to 740°C, and adding pure metal Zinc, pure metal magnesium, when adding metal magnesium, press the magnesium block completely below the liquid surface through the pressure cover; after these metals are melted and stirred evenly, the temperature is raised to 750°C, and the refining agent is us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com