Heat-insulating antibacterial nano-coating and a preparation method thereof

An antibacterial coating and nano-insulation technology, applied in fire-resistant coatings, reflective/signal coatings, anti-fouling/underwater coatings, etc., can solve the problems of poor heat insulation effect, complex process conditions, large coating shrinkage, etc., and achieve drying The effect of short process times, uniform particle distribution and few gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

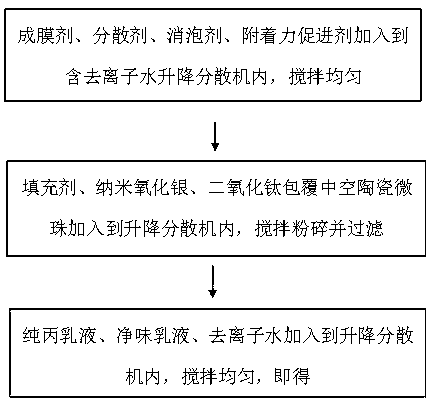

Method used

Image

Examples

Embodiment 1-10

[0032] A kind of nano heat-insulating antibacterial coating is made up of the raw material of following parts by weight:

[0033] Certain parts by weight of pure acrylic emulsion, certain parts by weight of pure acrylic emulsion, certain parts by weight of dispersant, certain parts by weight of adhesion promoter, certain parts by weight of film-forming agent, certain parts by weight of Filler, antifoaming agent in certain parts by weight, hollow microspheres in certain parts by weight, nano-silver oxide in certain parts by weight, deionized water in certain parts by weight, the specific raw material composition weight parts are shown in Table 1.

[0034] Preferably, the dispersant is made by mixing sodium dodecylbenzenesulfonate, silicon dioxide, and sodium hexametaphosphate in a mass ratio of 1:2:2. The dispersant can improve the dispersibility between particles in the coating and prevent particles from Mutual aggregation, so that the internal particle distribution of the obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com