Water extraction and foam separation method and foam separation device for tea saponin in camellia olefera cake

A technology of foam separation and camellia cake meal, which is applied in the directions of foam dispersion/prevention, chemical instruments and methods, sugar derivative preparation, etc., can solve the problems of low extraction yield and low purity of tea saponin, and achieves simple structure, Improved purity and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] Tea saponin is extracted from tea cake powder by a method comprising the following steps:

[0086]In step A, the degreased camellia oleifera cake passed through a 40-mesh sieve was fully mixed with deionized water at a constant temperature, the solid-to-liquid ratio was 8:1, the pH value was adjusted to 8.5, extracted with water for 90 minutes at a temperature of 50°C, and then extracted at 5000°C centrifuge for 5 minutes, and the resulting supernatant is the tea saponin initial extract. After drying to constant weight, crude tea saponin was obtained.

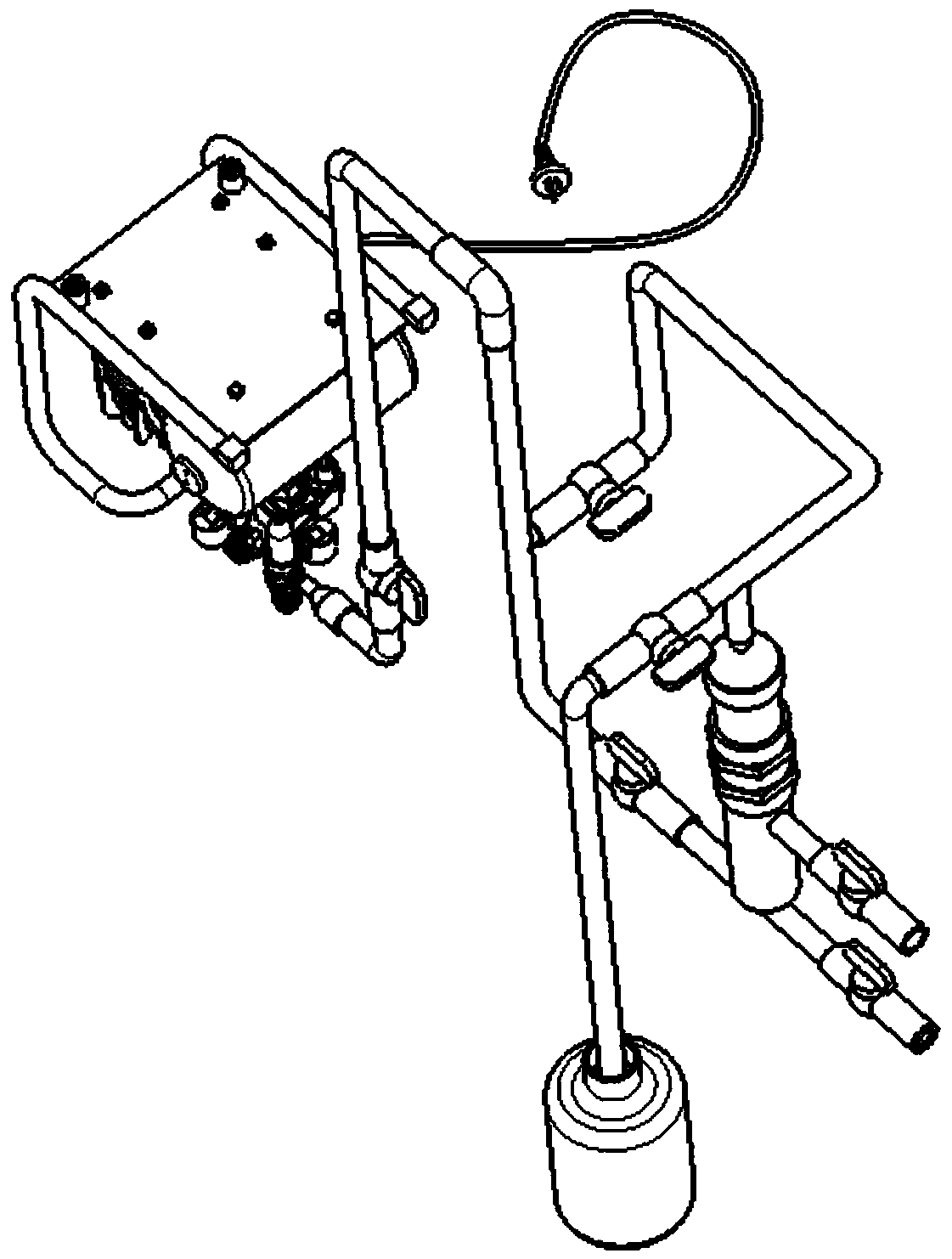

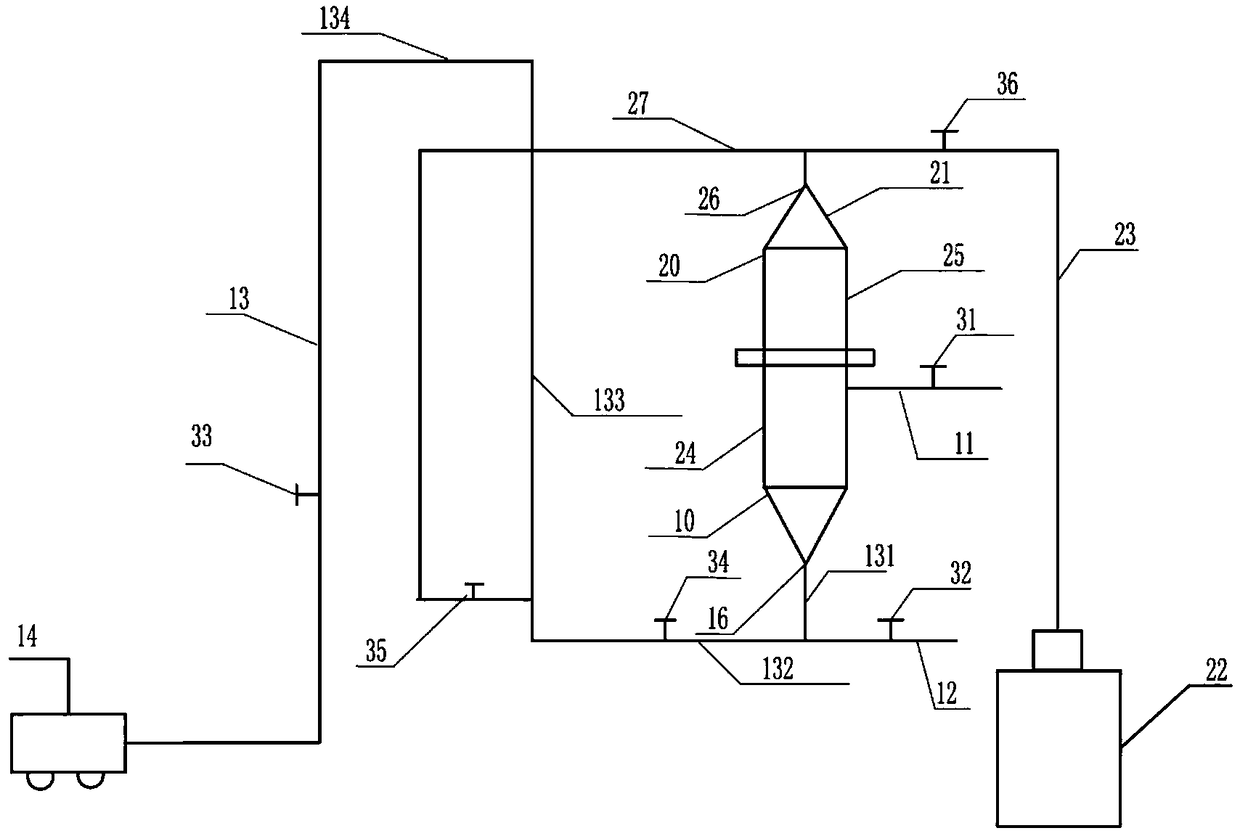

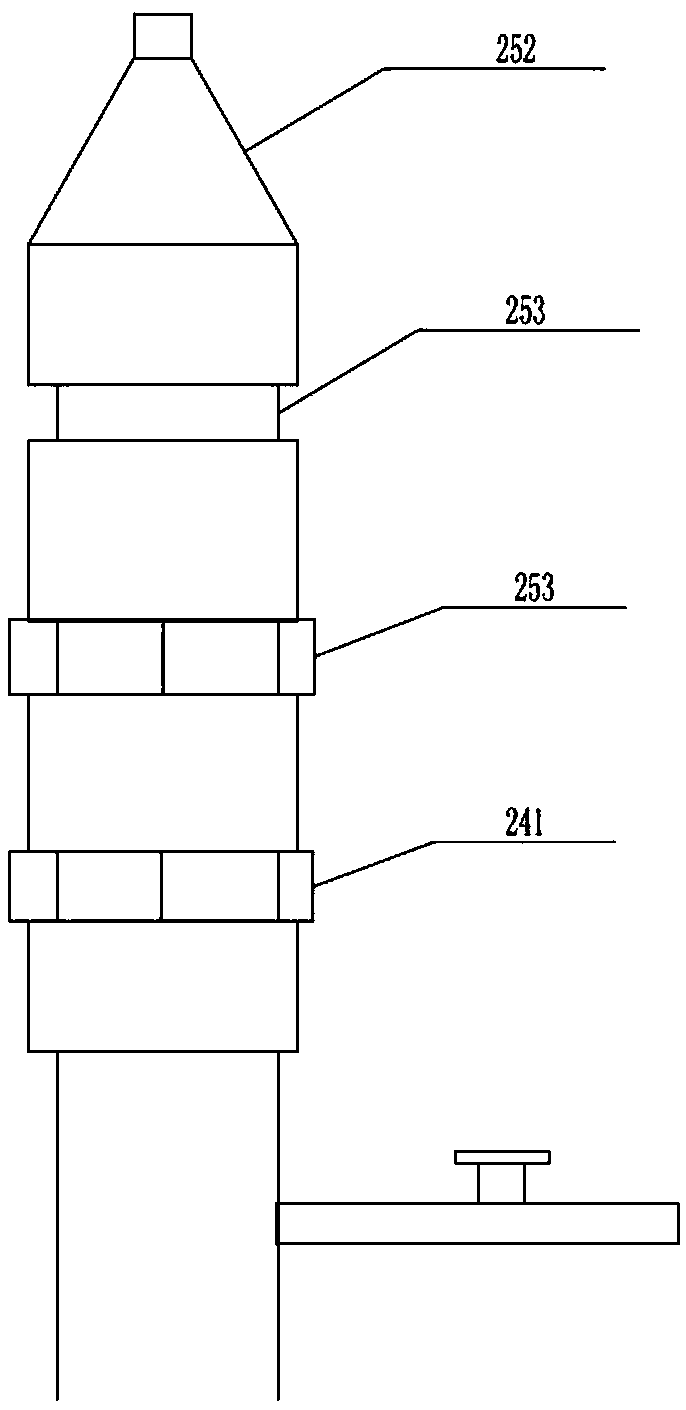

[0087] Step B, dissolving the crude tea saponin obtained in step A in deionized water, and configuring the solute concentration to be 1.5mg / mL crude tea saponin aqueous solution, the above-mentioned crude tea saponin aqueous solution is passed through the feed pipe 11 from the middle of the foam separation tower 21. The lower position is injected into the foam separation tower, the feed amount is 110mL, and the electrom...

Embodiment 2

[0092] Tea saponin is extracted from tea cake powder by a method comprising the following steps:

[0093] Step A, fully mix the defatted camellia oleifera cake that has passed through a 40-mesh sieve with deionized water at a constant temperature, the solid-to-liquid ratio is 8:1, adjust the pH value to 8.5, and extract with water for 120 minutes at a temperature of 40°C and an ultrasonic power of 600W , and then centrifuged on a 5000 / r centrifuge for 5 minutes, the resulting supernatant was the initial tea saponin extract. After drying to constant weight, crude tea saponin was obtained.

[0094] Step B, dissolve the crude tea saponin obtained in step A in deionized water, configure the solute concentration to be 2.0 mg / mL crude tea saponin aqueous solution, and pass the above crude tea saponin aqueous solution through the feed pipe 11 from the middle of the foam separation tower to the bottom The position is injected into the foam separation tower, and the feeding amount is ...

Embodiment 3

[0099] Tea saponin is extracted from tea cake powder by a method comprising the following steps:

[0100] Step A, fully mix the defatted camellia oleifera cake through a 40-mesh sieve with deionized water at a constant temperature, the solid-to-liquid ratio is 10:1, adjust the pH value to 9.5, extract with water for 150 minutes at a temperature of 50°C, and then extract at 5000°C centrifuge for 5 minutes on a centrifuge, and the resulting supernatant is the initial extraction of tea saponin. After drying to constant weight, crude tea saponin was obtained.

[0101] Step B, dissolve the crude tea saponin obtained in step A in deionized water, configure the solute concentration to be 1.0mg / mL crude tea saponin aqueous solution, pass the above-mentioned crude tea saponin aqueous solution through the feed pipe 11 from the middle of the foam separation tower to the bottom The position is injected into the foam separation tower, and the feeding amount is 110mL. The electromagnetic a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com