Red mud-based asphalt mixture warm-mixing agent and preparation method thereof

A technology of asphalt mixture and warm mix agent, which is applied in the field of asphalt warm mix agent, can solve the problems of reducing the water damage resistance of asphalt mixture, weakening the adhesion between asphalt and aggregate, and the high production cost of synthetic zeolite, so as to improve the resistance to water damage. Water damage ability, increase the freeze-thaw splitting strength ratio, and reduce the effect of comprehensive cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

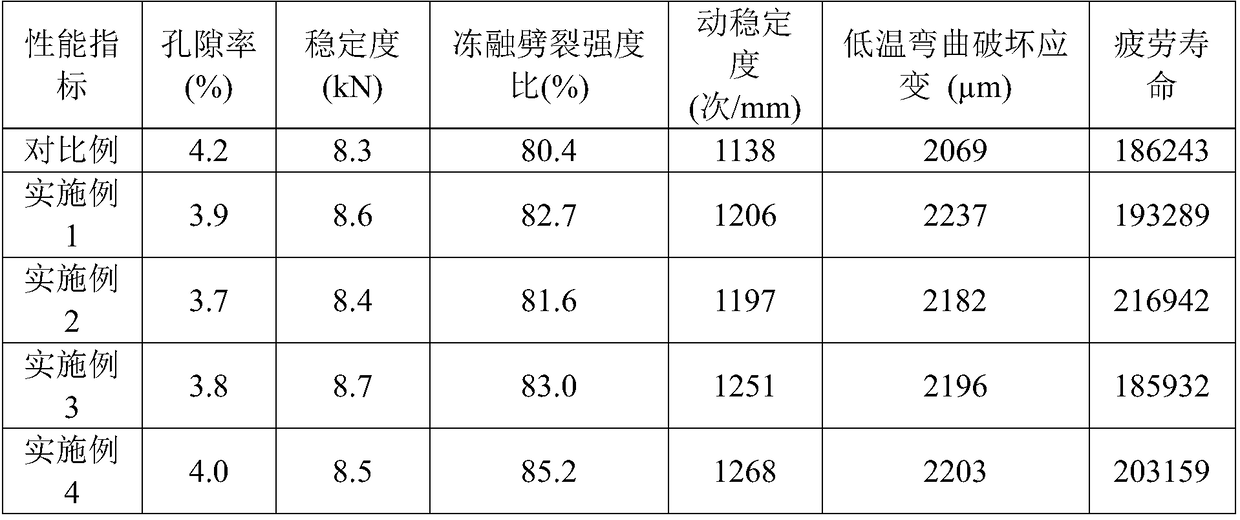

Examples

Embodiment 1

[0053] 1. A warm mixing agent for red mud-based asphalt mixture, comprising the following components in terms of mass percentage: 40% red mud, 55% active silicon-aluminum source, 2% alkaline activator, and 3% surfactant.

[0054] The active silicon-aluminum source is a mixture of granulated blast furnace slag and silicon powder, so that the SiO in the geopolymer precursor 2 / Al 2 o 3 The molar ratio was adjusted to 2:1.

[0055] The alkaline activator is a mixed aqueous solution of sodium silicate and sodium hydroxide, wherein the mass ratio of sodium silicate and sodium hydroxide is 1:1, and the solid content of the activator is 20%.

[0056] 2. The preparation method of the above red mud-based asphalt mixture warm mix agent is as follows:

[0057] (1) Calcining the red mud powder at 600°C for 1 hour, causing defects in the lattice structure of the original red mud, improving the pozzolanic activity of the red mud, thereby increasing the leaching rate of the red mud in the...

Embodiment 2

[0065] 1. A warm mix agent for red mud-based asphalt mixture, comprising the following components by mass percentage: 50% red mud, 35% active silicon-aluminum source, 10% alkaline activator, and 5% surfactant.

[0066] The active silicon-aluminum source is a mixture of granulated blast furnace slag and silicon powder, so that the SiO in the geopolymer precursor 2 / Al 2 o 3 The molar ratio was adjusted to 3:1.

[0067] The alkaline activator is a mixed aqueous solution of sodium silicate and sodium hydroxide, the mass ratio of sodium silicate and sodium hydroxide is 1:2, and the solid content of the activator is 30%.

[0068] 2. The preparation method of the above red mud-based asphalt mixture warm mix agent is as follows:

[0069] (1) Calcining the red mud powder at 700°C for 2 hours, causing defects in the lattice structure of the original red mud, improving the pozzolanic activity of the red mud, thereby increasing the leaching rate of the red mud in the alkaline activato...

Embodiment 3

[0077] 1. A warm mixing agent for red mud-based asphalt mixture, comprising the following components in terms of mass percentage: 70% red mud, 30% active silicon-aluminum source, 8% alkaline activator, and 2% surfactant.

[0078] The active silicon-aluminum source is a mixture of granulated blast furnace slag and silicon powder, so that the SiO in the geopolymer precursor 2 / Al 2 o 3 The molar ratio was adjusted to 4:1.

[0079] The alkaline activator is a mixed aqueous solution of sodium silicate and sodium hydroxide, the mass ratio of sodium silicate and sodium hydroxide is 1:3, and the solid content of the activator is 30%.

[0080] 2. The preparation method of the above red mud-based asphalt mixture warm mix agent is as follows:

[0081](1) Calcining the red mud powder at 800°C for 3 hours, causing defects in the lattice structure of the original red mud, improving the pozzolanic activity of the red mud, thereby increasing the leaching rate of the red mud in the alkalin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com