Method for treating nickel-containing wastewater by using recycled kieselguhr

A technology of silicon bath soil and nickel wastewater, applied in water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve problems such as heavy environmental burden, waste, and affecting smooth production, and achieve shortening Processing time, convenient operation, and the effect of ion exchange capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

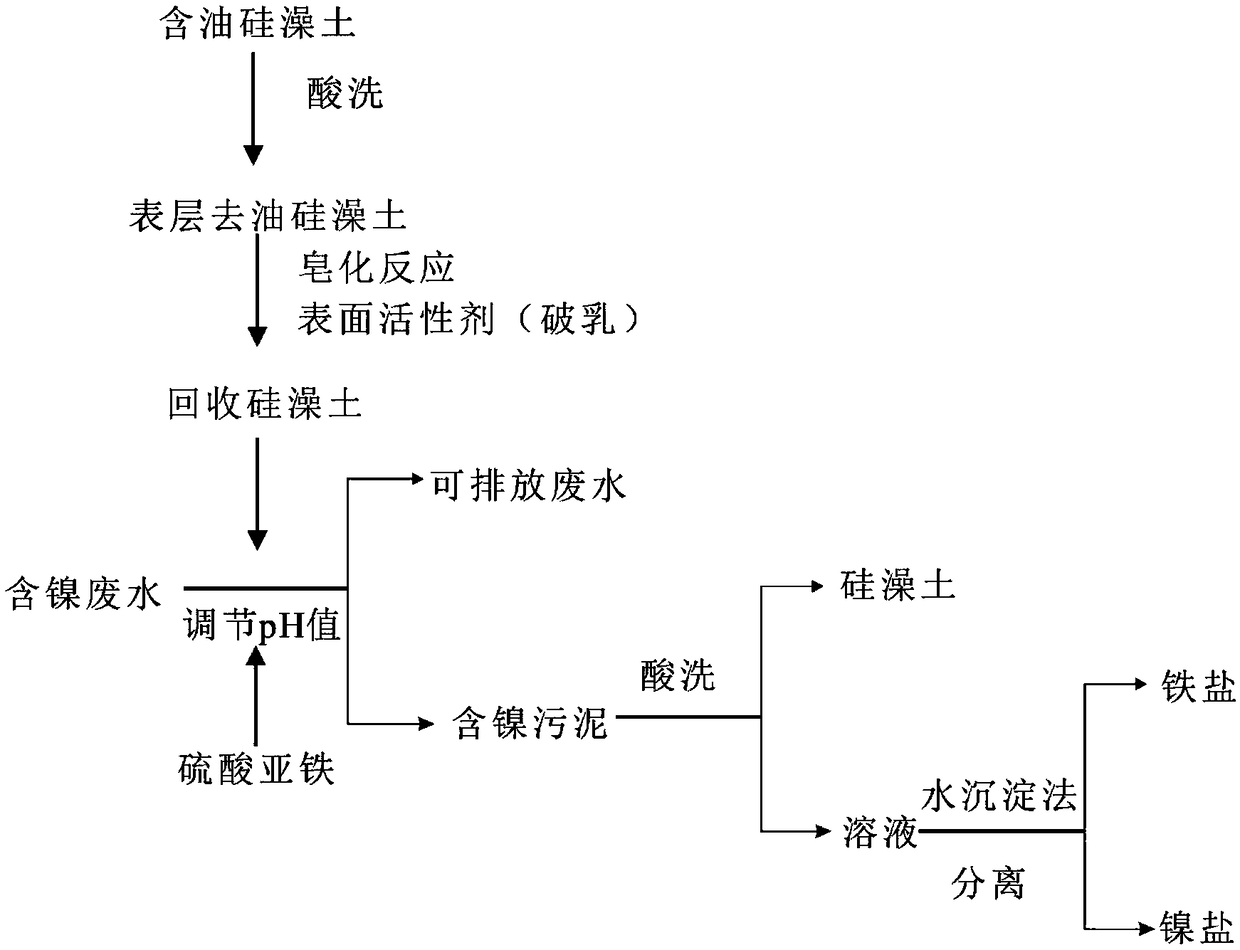

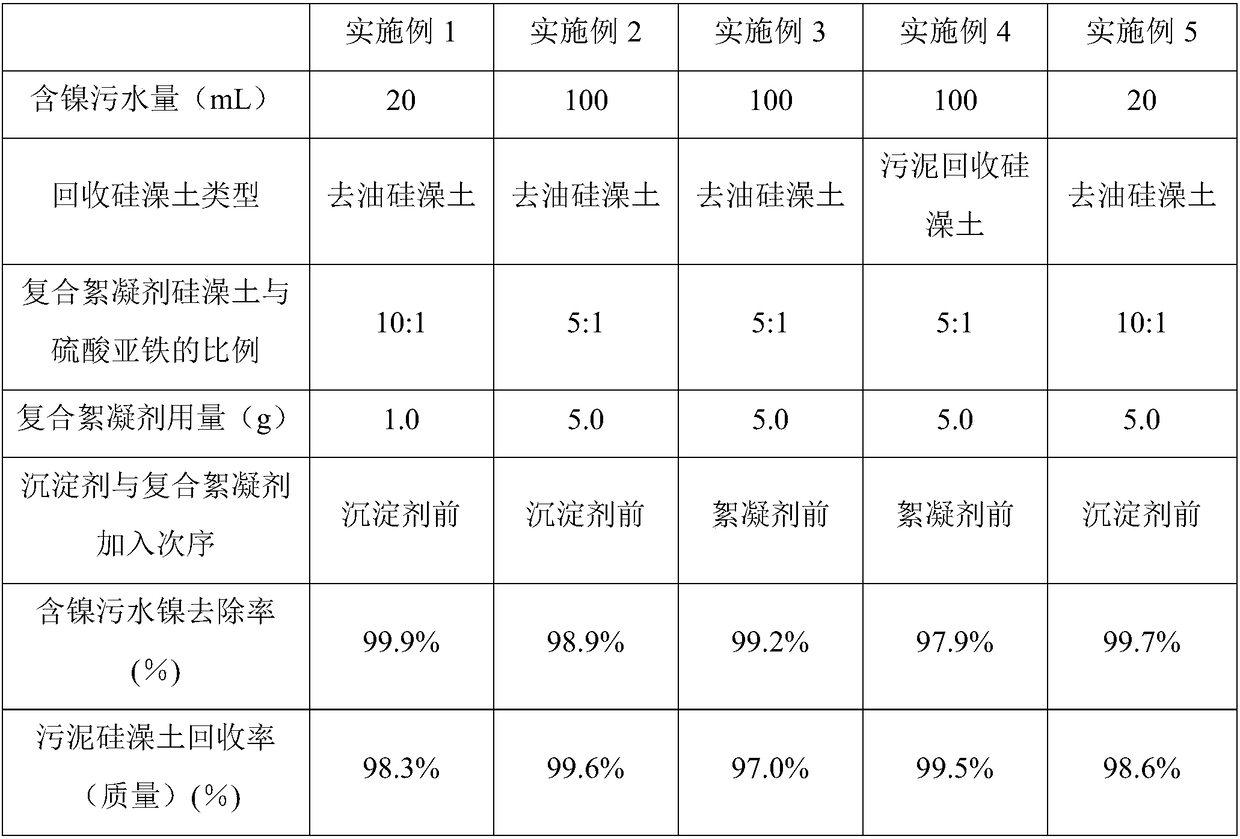

[0032] ① The waste diatomite filter aid used in the aluminum products industry for rolling oil purification and filtration is washed with sulfuric acid to remove oil from the surface, and then saponified with sodium hydroxide at a certain temperature to remove oil in depth, washed, filtered and dried, and recycled Diatomaceous earth can be used.

[0033] ② Mix the silicon bath soil recovered in step ① with ferrous ferrite in a mass ratio of 10:1.

[0034] ③ Add 2 mol / L hydroxide to 20 mL of nickel ion-containing simulated wastewater (0.08 mol / L nickel sulfate aqueous solution) to adjust the pH to about 9, then add 0.5 g of silicon bath soil-ferrous salt composite flocculant for co-precipitation, Air is blown in, stirred for 5 minutes to make it fully react, and after the reaction is completed, filter to complete the treatment of nickel ion-containing wastewater. The content of nickel ions in the solution before and after treatment was determined by spectrophotometry.

[0035...

Embodiment 2

[0040] ① same as embodiment 1

[0041] ② Mix the silica bath soil recovered in step ① with ferrous ferrite in a mass ratio of 5:1.

[0042] ③ Add 2 mol / L hydroxide to 100 mL of simulated wastewater containing nickel ions (0.08 mol / L nickel sulfate aqueous solution) to adjust the pH to about 9, and then add 5 grams of silicon bath soil-ferrous salt composite flocculant for co-precipitation, Air is blown in, stirred for 5 minutes to make it fully react, and after the reaction is completed, filter to complete the treatment of nickel ion-containing wastewater. The content of nickel ions in the solution before and after treatment was determined by spectrophotometry.

[0043] ④-⑦Example 1

Embodiment 3

[0045] ① same as embodiment 1

[0046] ② Mix the silica bath soil recovered in step ① with ferrous ferrite in a mass ratio of 5:1.

[0047] ③In 100mL of simulated wastewater containing nickel ions (0.08mol / L nickel sulfate aqueous solution), add 5.0 grams of silicon bath soil-ferrous salt composite flocculant, then add a certain amount of hydroxide precipitant, blow in air, and stir for 5 minutes to make it Fully react, after the reaction is finished, filter to complete the treatment of nickel ion-containing wastewater. The content of nickel ions in the solution before and after treatment was determined by spectrophotometry.

[0048] ④-⑦Example 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com