Wire hangers for automotive wiring harness production

An automobile wiring harness and wire hanging machine technology, applied in the field of wire hanging machines, can solve the problems of cluttered workshop environment, hinder production processing, reduce production efficiency, etc., and achieve the effect of being easy to idle, reducing the types of tools, and occupying a small space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific embodiments. The exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not as a limitation to the present invention.

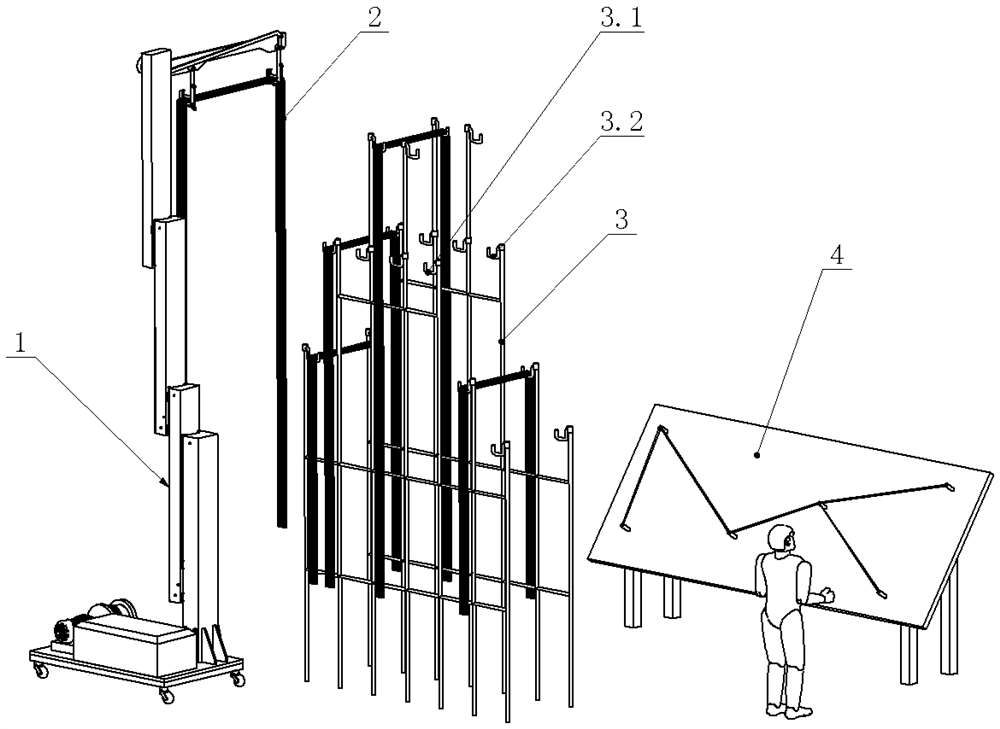

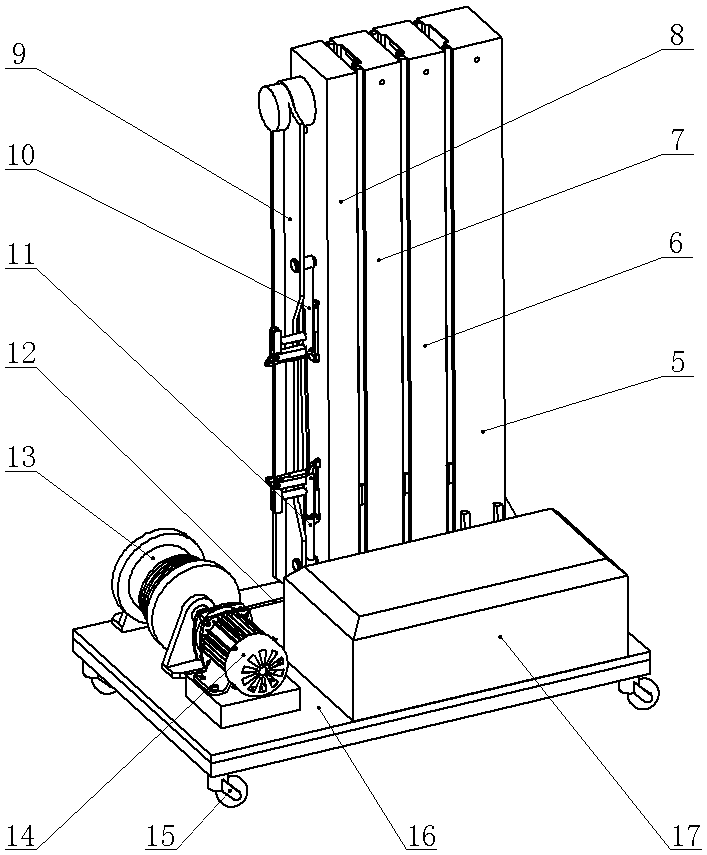

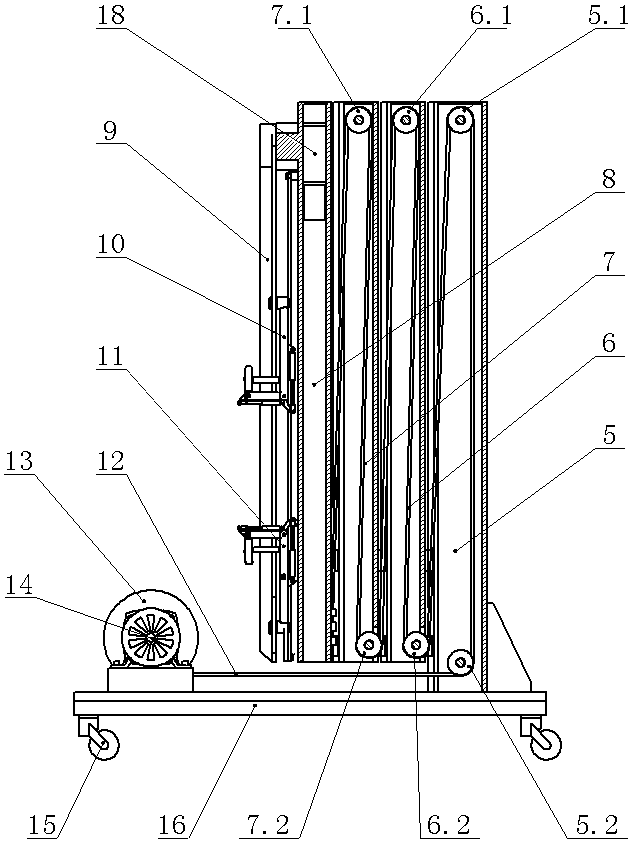

[0020] Such as figure 1 , figure 2 As shown, the wire hanging machine used in the production of automobile wiring harness includes the first arm 5, the second arm 6, the third arm 7, the fourth arm 8, the cross arm 9, the right hook 10, the left hook 11, the wire rope 12, the winch Tube 13, winch motor 14, universal wheel 15, chassis 16, counterweight 17, worm gear motor 18, connecting rod 19, is characterized in that: the first arm 5, the second arm 6, the third arm 7 and the first arm The four arms 8 are connected in turn to form a lifting structure. The hoisting motor 14 drives the hoisting drum 13 to rotate, and the hoisting drum 13 drives the lifting motion of the hoisting structure through the hoisting wire ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com