Device for semi-dry desulfurization, dust removal and low-temperature denitration of coke oven flue gas and technological method thereof

A semi-dry desulfurization and low-temperature denitrification technology, which is applied in the field of flue gas purification equipment, can solve the problems of cross-leakage between carbonization chamber and combustion chamber, high investment and operation costs, and low concentration of sulfur dioxide, achieving remarkable social and economic benefits , Low investment costs, low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

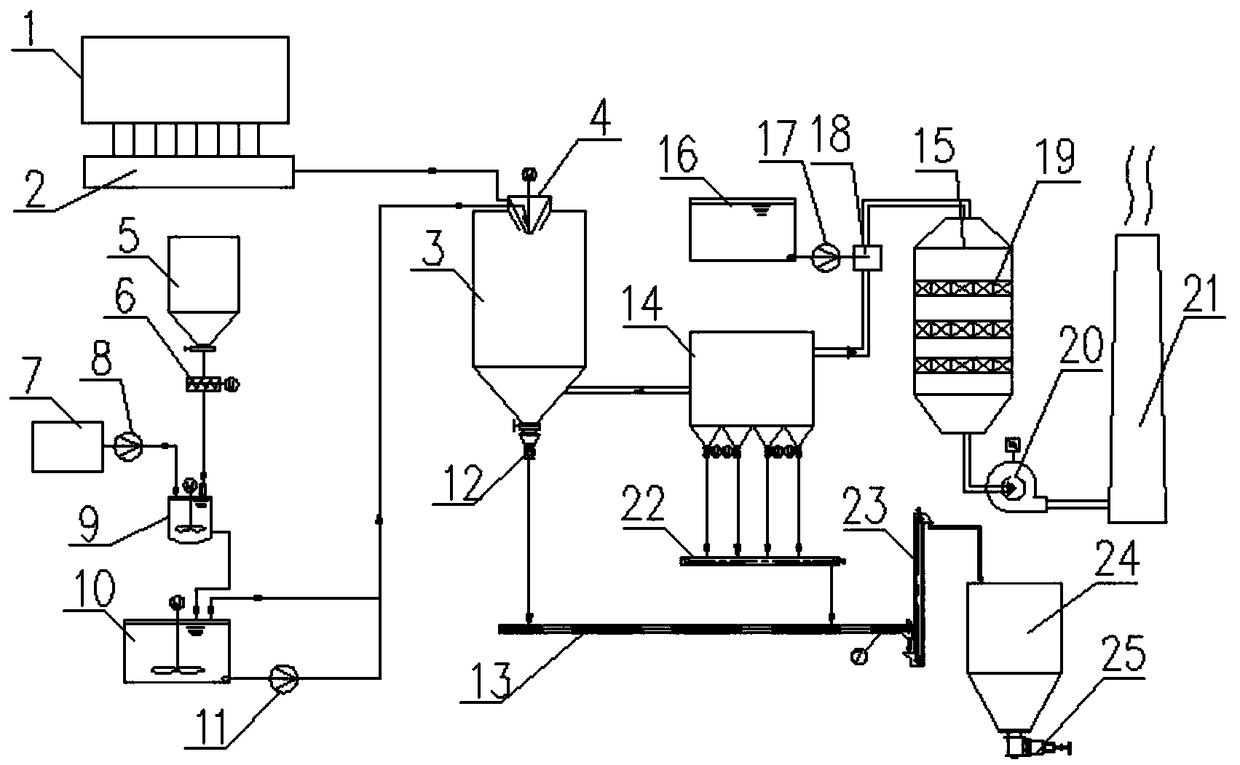

[0028] Such as figure 1 As shown, the coke oven flue gas semi-dry desulfurization, dust removal and low-temperature denitrification device described in the present invention includes: coke oven 1, flue 2, semi-dry desulfurization tower 3, rotary atomizer 4, absorbent Powder bin 5, screw weighing scale 6, process water tank 7, process water pump 8, slurry tank 9, slurry storage tank 10, slurry delivery pump 11, ash unloading valve at the bottom of the tower 12, scraper conveyor 13, bag filter 14, SCR reactor 15, ammonia water tank 16, ammonia water pump 17, ammonia water evaporation mixer 18, low temperature catalyst 19, induced draft fan 20, chimney 21, screw conveyor 22, bucket elevator 23, ash storage 24, ash discharge valve 25.

[0029]In the above device, the coke oven 6, the semi-dry desulfurization tower 3, the bag filter 14, the SCR reactor 15, the induced draft fan 20 and the chimney are connected in sequence through the flue. The rotary atomizer 4 is installed on the...

Embodiment 2

[0035] The technical method of coke oven flue gas semi-dry desulfurization, dust removal and low temperature denitrification device of the present invention comprises the following steps:

[0036] Step 1: The coke oven flue gas from the tail of the coke oven 1 is sent into the desulfurization tower through the flue 2, and the absorbent slurry is pumped into the rotary atomizer 4 at the top of the absorption tower;

[0037] Step 2: In the absorption tower, the absorbent atomized into fine liquid droplets is mixed with the flue gas and contacts with the SO in the flue gas 2 A chemical reaction occurs to generate sulfate, SO in the flue gas 2 At the same time, the moisture brought in by the absorbent is quickly evaporated and dried, and the temperature of the flue gas decreases accordingly;

[0038] Step 3: Part of the desulfurization reaction product and a small amount of unused desulfurization absorbent are discharged from the outlet of the cone at the bottom of the desulfuriz...

Embodiment 3

[0047] Suppose there is a 5.5m coke oven with a flue gas flow rate of 120000Nm 3 / h emission, the flue gas temperature can reach 270°C, and the sulfur dioxide concentration in the flue gas is 200mg / Nm 3 , nitrogen oxide concentration 800mg / Nm 3 , dust concentration 40mg / Nm 3 , moisture content 15%. The desulfurization absorbent is slaked lime, and the denitrification reducing agent is 25% ammonia water.

[0048] Such as figure 1 As shown, the 270°C flue gas from the coke oven 1 enters the semi-dry desulfurization tower 3 through the flue 2, and the lime stored in the absorbent powder bin 5 is sent to the pulping tank 9 through the screw weighing scale 6, and the process water tank The process water in 7 is sent to the slurry tank 9 through the process water pump 8 to make slaked lime milk, which flows into the slurry storage tank 10, and the slaked lime milk is pumped into the rotary atomizer 4 located in the absorption tower by the slurry delivery pump 11. In the absorpt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com