Processing method for thread residues during garment making

A processing method and thread end technology, applied in the field of invention, can solve the problems of thread end treatment, affecting the quality of clothes, unable to guarantee the quality and neat appearance of clothes, etc., and achieve the effects of preventing thread ends from bifurcation, ensuring the quality of clothes, and increasing the firmness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

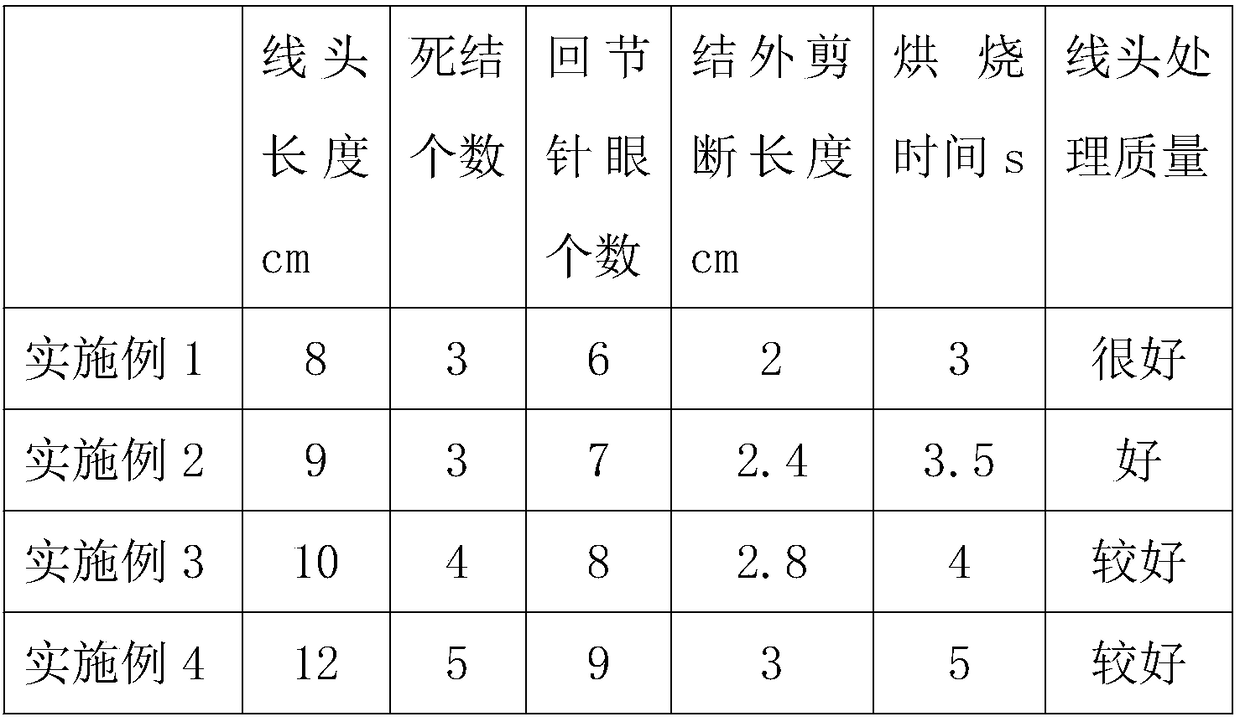

Embodiment 1

[0023] (1) At the end of garment making, when the needle is sewn to the last stitch, the length of the thread left is 8cm;

[0024] (2) Tie the end of the thread left in the process (1) as a dead knot, the number of dead knots is 3, and the shape and size of the dead knot remain the same;

[0025] (3) Insert the thread end tied to the dead knot in process (2) through the thread puller along the needle eye at the end of the line to the back section, and pull it out from the needle eye at the end point to the sixth needle eye in the back section, and pull it slightly with your hand Pull the end of the thread until the knot is no longer visible;

[0026] (4) Cut the end of the thread pulled out in process (3), cut the end of the thread 2cm away from the tie, and retract the end of the thread along the eye of the needle;

[0027] (5) Use the flame of a lighter to burn even the thread cut in the process (4). The baking time is 3s to burn even the branched thread.

Embodiment 2

[0029] (1) When the needle is sewn to the last stitch at the end of garment making, the length of the thread left is 9cm;

[0030] (2) Tie the end of the thread left in the process (1) as a dead knot, the number of dead knots is 3, and the shape and size of the dead knot remain the same;

[0031] (3) Insert the end of the thread tied to the dead knot in the process (2) through the thread puller along the needle eye at the end of the line to the retracement, and pull it out from the needle eye at the end point to the seventh needle eye of the retracement, and pull it slightly with your hand Pull the end of the thread until the knot is no longer visible;

[0032] (4) Cut the end of the thread pulled out in process (3), cut the end of the thread 2.4cm away from the tie, and retract the end of the thread along the eye of the needle;

[0033] (5) Use the flame of a lighter to burn the thread cut in the process (4), and the baking time is 3.5s, which is used to burn even the branched thread...

Embodiment 3

[0035] (1) When the needle is sewn to the last stitch at the end of garment making, the length of the thread left is 10cm;

[0036] (2) Tie the end of the thread left in the process (1) as a dead knot, the number of dead knots is 4, and the shape and size of the dead knot remain the same;

[0037] (3) Insert the thread end tied to the dead knot in process (2) through the thread puller along the needle eye at the end of the line to the back section, and pull it out from the needle eye at the end point to the eighth needle eye in the back section, and pull it slightly with your hand Pull the end of the thread until the knot is no longer visible;

[0038] (4) Cut the end of the thread pulled out in process (3), cut the end of the thread 2.8cm away from the tie, and retract the end of the thread along the eye of the needle;

[0039] (5) Use the flame of a lighter to burn even the thread cut in the process (4). The baking time is 4s, which is used to burn even the branched thread.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com