Devices for preventing the spread of sparks

A technology of sparks and hydraulic joints, applied in transportation and packaging, pipes/pipe joints/fittings, aircraft lighting protectors, etc., can solve the problems of composite materials or non-conductive fuel tanks accumulating and depositing static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

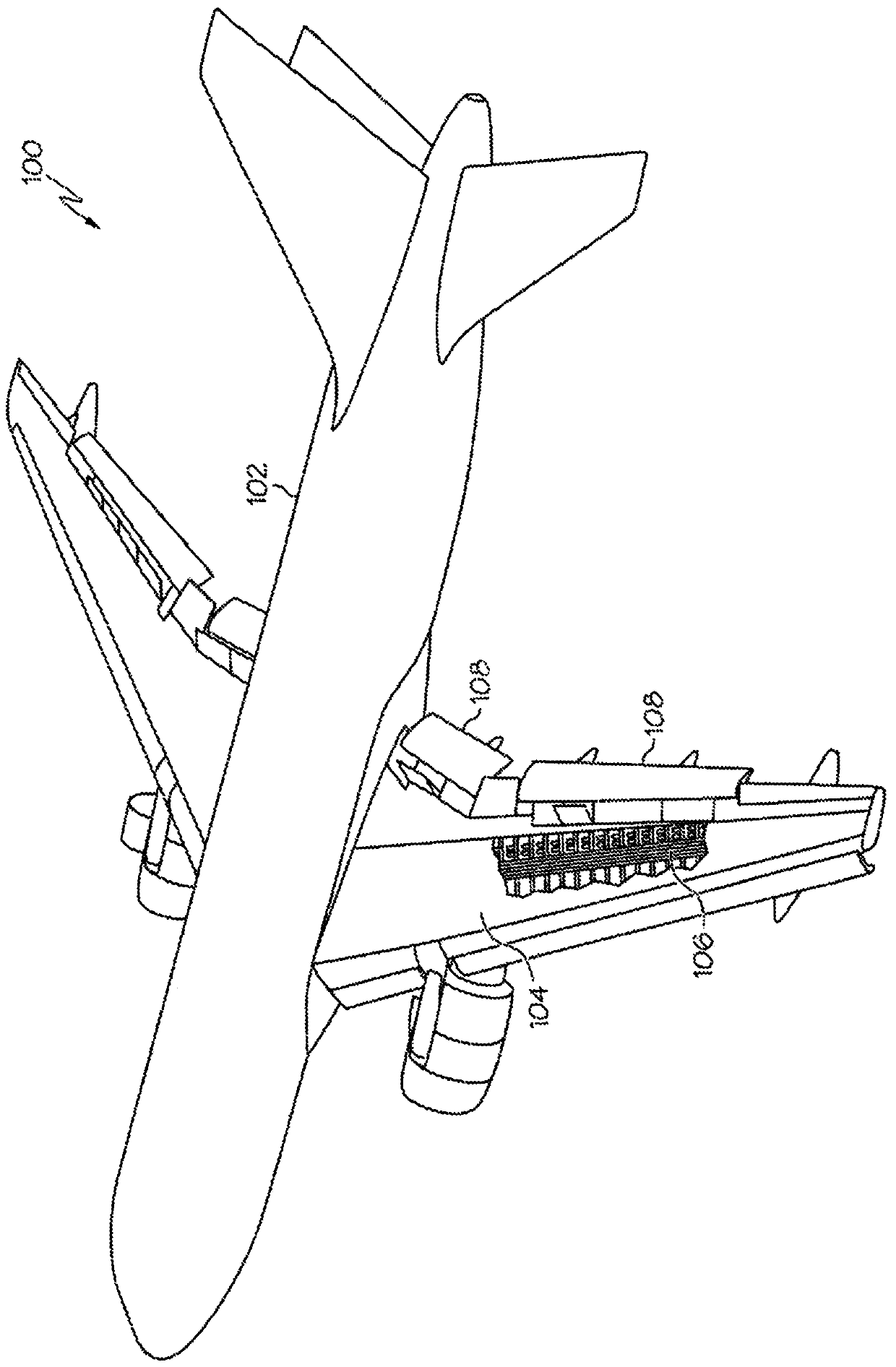

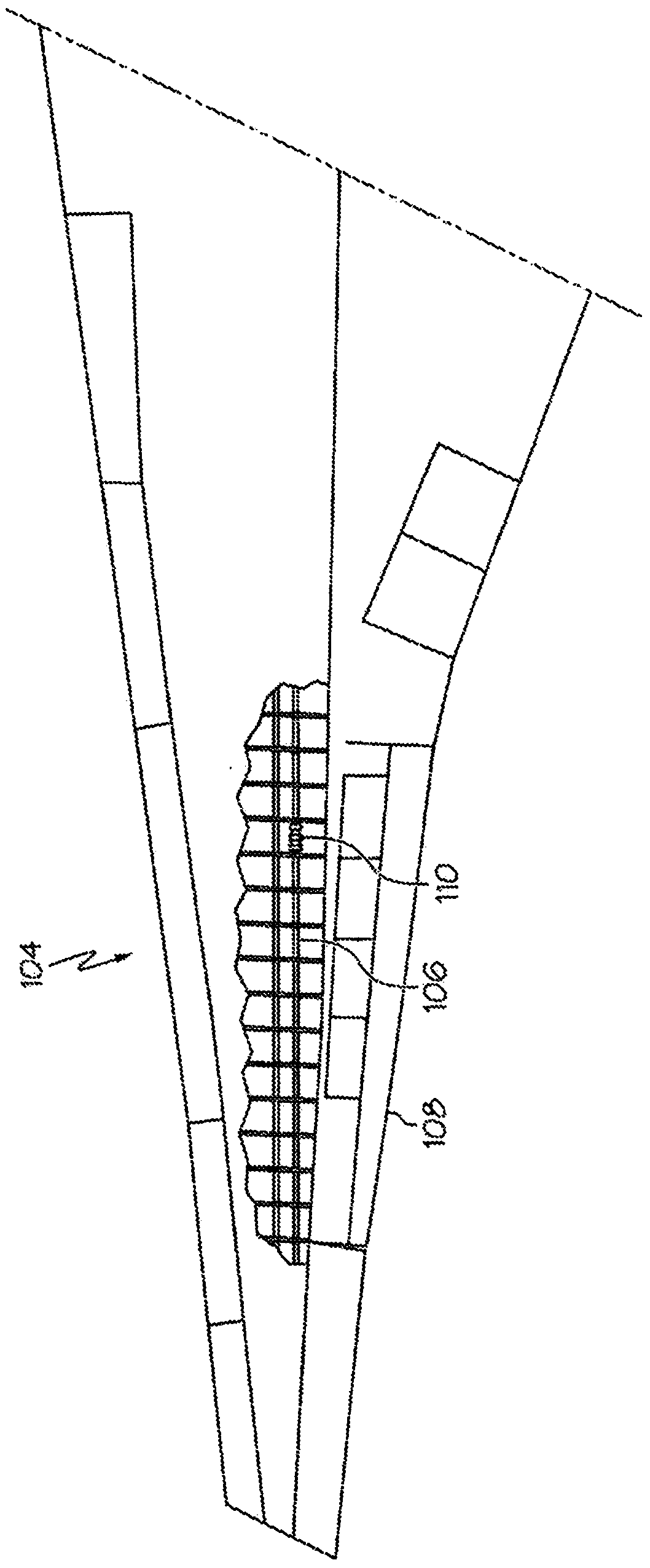

[0056] Such as figure 1 As shown in , a commercial aircraft 100 generally consists of a fuselage 102 , wings 104 including hydraulic lines 106 and flaps 108 . Flaps 108 are placed on wing 104 to provide flight control for the aircraft. Such as figure 2 As shown in , hydraulic lines 106 may pass through wings 104 of the aircraft and may include one or more hydraulic connections 110 . These hydraulic lines 106 may control flaps 108 or other control structures of the aircraft.

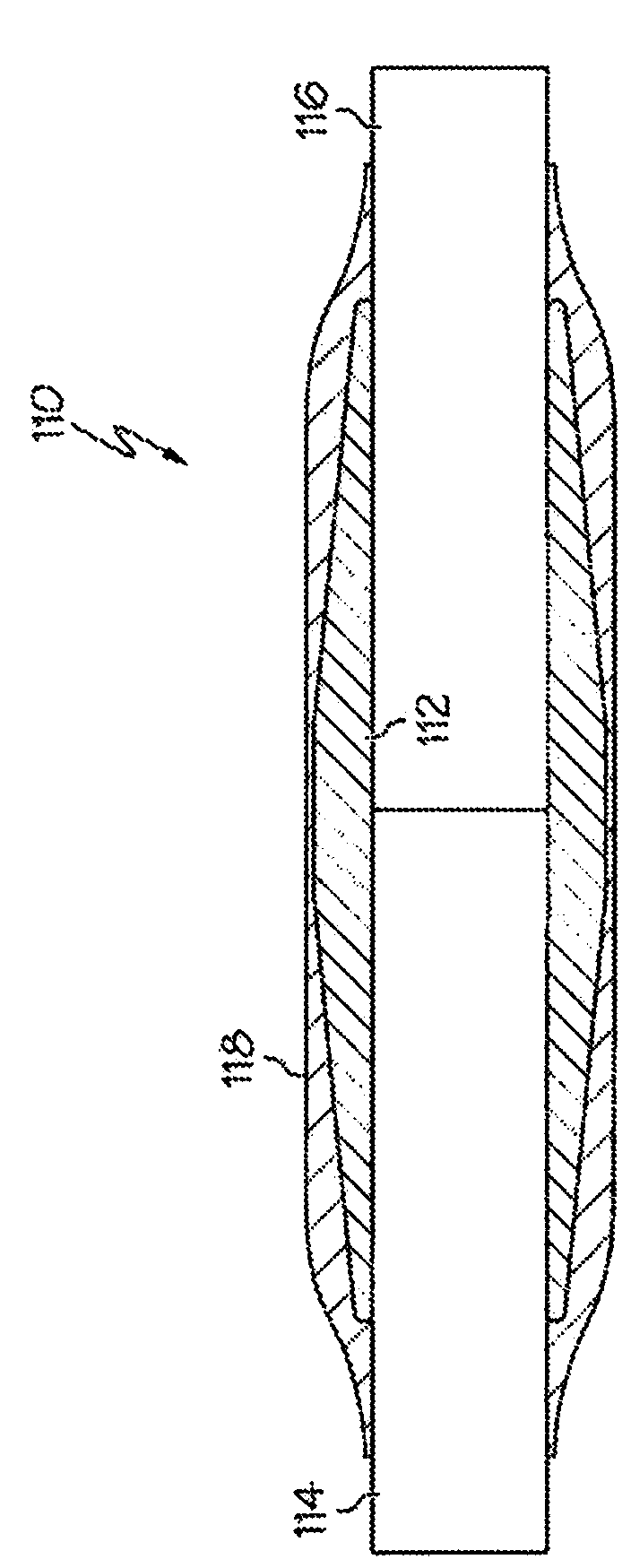

[0057] image 3 A cross-sectional view of one embodiment of the improved device is shown. As shown in this figure, hydraulic connections 110 generally consist of hydraulic joints 112 positioned generally around hydraulic lines 114 , 116 . In this illustration, hydraulic coupling 112 is a connector for connecting first section 114 of hydraulic line 106 to second section 116 . The first section 114 and the second section 116 of the hydraulic line 106 may be secured by swaging or any other method gene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com