Steel cord, its production method and inflatable tyre containing said steel cord

A steel and cord technology, which is applied in the reinforcement layers of pneumatic tires, tire parts, auxiliary devices for rope making, etc. Poor and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

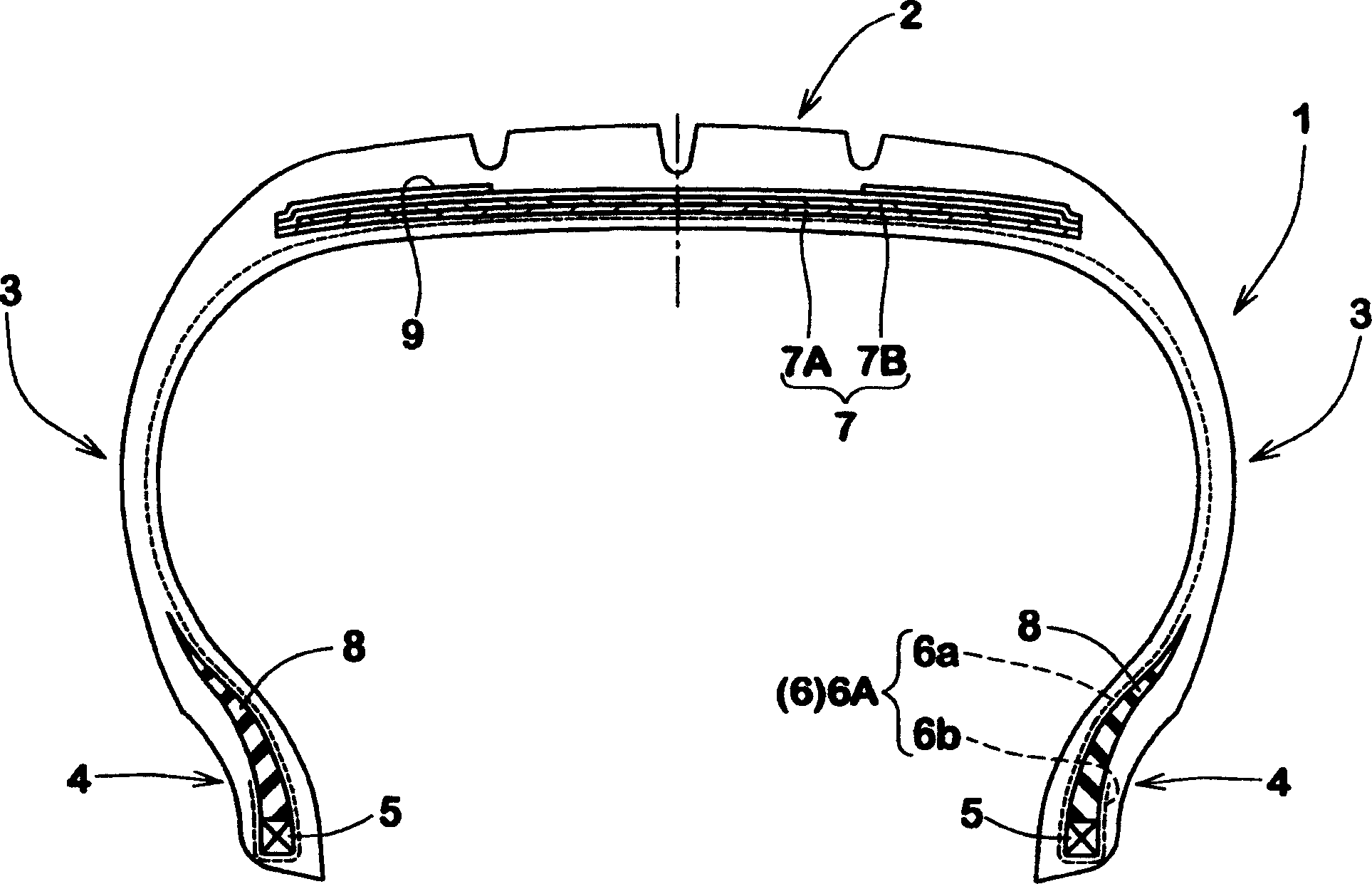

[0017] In the drawings, a pneumatic tire 1 according to the present invention includes a tread portion 2, a pair of sidewall portions 3, and a pair of bead portions 4 each having a core 5 therein, the bead portions extending between the bead portions 4. The carcass 6 and the belts 7 , 9 arranged outside the carcass 6 in the tread portion 2 .

[0018] In this embodiment, the tire 1 is a radial tire for passenger cars.

[0019] The carcass 6 is composed of at least one cord layer 6A placed radially at an angle of 75 to 90 degrees with respect to the tire equator, between the bead portions 2 along the tread portion 2 and the tire The side portions 3 extend and turn up the core 5 in each bead portion 4 from the inside to the outside of the tire so as to form a pair of turn-up portions 6b and a main body portion 6a between the turn-up portions. In this embodiment, organic fibers such as nylon, rayon, and polyester are used as the carcass cords. In each bead portion 4, between the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com