Battery module and use of such battery module

A technology of battery packs and lithium-ion battery packs, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of battery runaway, safety risks, etc., and achieve the effect of preventing heat conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

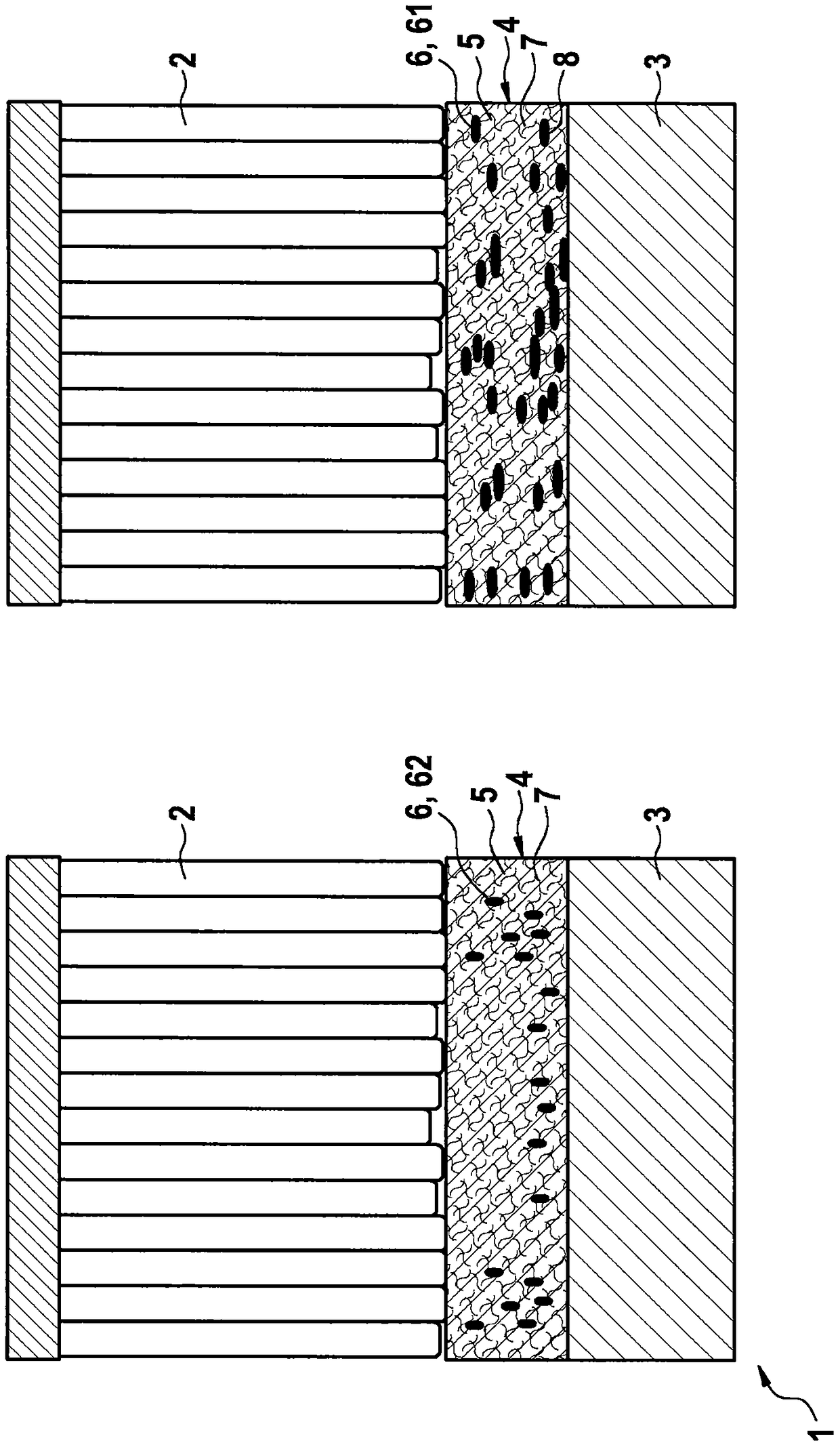

[0044] figure 1 An embodiment of a battery module 1 is shown schematically.

[0045] The battery module 1 here comprises at least one battery cell 2 , in particular a lithium-ion battery cell.

[0046] Furthermore, the battery module 1 includes a cooling plate 3 . In this case, the cooling plate 3 is thermally connected to at least one battery cell 2 .

[0047] In order to increase the thermal conductivity between the at least one battery cell 2 and the cooling plate 3 , a thermal equalization layer 4 is arranged between the at least one battery cell 2 and the cooling plate 3 .

[0048] In this case, the thermal equalization layer 4 is formed from a base material 5 . The base material 5 of the thermal equalization layer 4 is preferably formed here from an electrically insulating material 7 . For example, the base material can be formed from silicone or epoxy and can additionally comprise a thermally conductive filler material in order to increase the thermal conductivity. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com