Thick steel plate suitable for large heat input welding in EH420 grade marine engineering and preparation method thereof

A technology for high-energy welding and marine engineering, applied in metal rolling and other directions, can solve the problems of limited ability of intragranular ferrite nucleation and microstructure refinement, unfavorable high-energy welding performance of thick steel plates, complex production process, etc. Achieve the effect of promoting the nucleation ability of intragranular acicular ferrite, strengthening the nucleation ability of intragranular acicular ferrite, and facilitating the popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

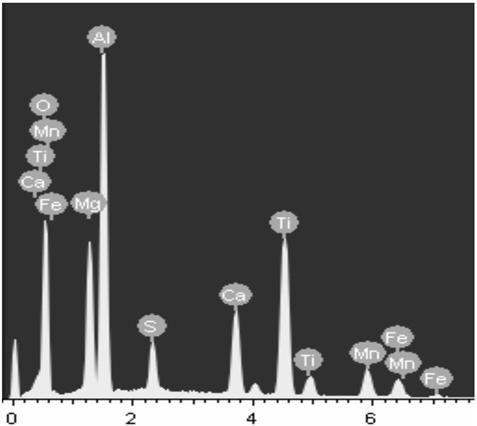

[0031] In this example, EH420-grade thick steel plates for marine engineering can be welded with large heat input, and the chemical composition of the steel plates includes: C 0.05%, Si 0.2%, Mn 1.7%, P 0.005%, S 0.002%, Nb 0.01 %, Ti0.005%, Cu 0.2%, Ni 0.5%, N 0.006%, O 0.001%, Al 0.005%, Mg 0.001%, Ca0.001%, the balance is Fe; Al-Mg-Ti-Ca-Mn-O-S composite inclusions accounted for 30%; Al-Mg-Ti-Ca-Mn-O-S inclusions contained 10% Al and 5% Mg on average by mass fraction , Ti10%, Ca 8%, 30% of the inclusions contain magnesium aluminum spinel structure inside, and the outer layer contains Ca oxysulfide and Mn sulfide.

[0032] The above steel plate preparation method includes the following steps: using deep desulfurized molten iron and low-sulfur steel scrap, the scrap steel ratio is ≤ 10%, adding silico-manganese to the ladle for deoxidation alloying when the steel output of the converter is 1 / 3, and the oxygen content of the molten steel after the furnace is 10ppm ; Add ferro...

Embodiment 2

[0036] In this embodiment, EH420 grade thick steel plate for ocean engineering can be welded with large heat input, and the chemical composition of the steel plate includes: C 0.08%, Si 0.3%, Mn 1.5%, P 0.001%, S 0.004%, Nb 0.03 %, Ti0.015%, Cu 0.4%, Ni 0.3%, N 0.005%, O 0.003%, Al 0.01%, Mg 0.0005%, Ca0.005%, the balance is Fe; Al-Mg-Ti-Ca-Mn-O-S composite inclusions accounted for 40%; Al-Mg-Ti-Ca-Mn-O-S inclusions contained an average of 12% Al and 6% Mg by mass fraction , Ti15%, Ca 10%, 40% of the inclusions contain magnesium aluminum spinel structure inside, and the outer layer contains Ca oxysulfide and Mn sulfide.

[0037] The above-mentioned steel plate preparation method includes the following steps: using deep desulfurized molten iron and low-sulfur steel scrap, the scrap steel ratio is ≤ 10%, adding silico-manganese to the ladle for deoxidation alloying when the steel output of the converter is 1 / 2, and the oxygen content of the molten steel after the furnace is 150p...

Embodiment 3

[0041] In this example, EH420-grade thick steel plates for marine engineering can be welded with large heat input, and the chemical composition of the steel plates includes: C 0.12%, Si 0.1%, Mn 1.0%, P 0.01%, S 0.005%, Nb 0.04 %, Ti0.025%, Cu 0.5%, Ni 0.5%, N 0.001%, O 0.001%, Al 0.025%, Mg 0.005%, Ca0.0005%, the balance is Fe; Al-Mg-Ti-Ca-Mn-O-S composite inclusions accounted for 50%; Al-Mg-Ti-Ca-Mn-O-S inclusions contained an average of 15% Al and 7% Mg by mass fraction , Ti10%, Ca 5%, 50% of the inclusions contain magnesium aluminum spinel structure inside, and the outer layer contains Ca oxysulfide and Mn sulfide.

[0042] The above steel plate preparation method includes the following steps: using deep desulfurized molten iron and low-sulfur steel scrap, the scrap steel ratio is ≤ 10%, adding silicon manganese to the ladle for deoxidation alloying when the steel output of the converter is 2 / 3, and the oxygen content of the molten steel after the furnace is 200ppm Add fe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com