Lithium battery diaphragm ceramic slurry with high temperature resistance and preparation method thereof

A ceramic slurry, high temperature resistance technology, used in lithium batteries, separators/films/diaphragms/spacers, circuits, etc., can solve problems such as poor dimensional stability, and achieve excellent heat resistance and coating technology. Simple, good heat resistant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment provides a preparation method for lithium-ion battery separator slurry, the method comprising the following steps:

[0035] (1) First put all the solvents, i.e. 15 kg of ethanol and 40.3 kg of deionized water into the reactor, and stir for 10 min at 1500 rpm;

[0036] (2) Keep stirring and put 0.4 kg of sodium polyacrylate, 0.8 kg of wetting agent, 0.1 kg of defoamer, and 0.3 kg of rheological additive into the reactor at one time, and stir at 1500rpm for 15min;

[0037] (3) After mixing evenly, slowly put 5 kg of adhesive emulsion into the reaction kettle and stir for 10 minutes;

[0038] (4) Put 30.4 kg of the first heat-resistant ceramic (alumina particles) and 7.6 kg of the second heat-resistant ceramic (silicon carbide whisker) into the reaction kettle, and stir at 1500rpm for 0.5h;

[0039] (5) Add 0.1 kg of thickener into the reaction kettle, and stir for 1 hour at 1500 rpm;

[0040] (6) After the slurry is mixed evenly, weigh and pack.

Embodiment 2

[0042] This embodiment provides a preparation method for lithium-ion battery separator slurry, the method comprising the following steps:

[0043] (1) First put all solvents, i.e. 15 kg of ethanol and 41.2 kg of deionized water into the reactor, and stir at 1500rpm for 10min;

[0044] (2) Keep stirring and put 0.4 kg of sodium polyacrylate, 0.8 kg of wetting agent, 0.1 kg of defoamer, and 0.3 kg of rheological additive into the reactor at one time, and stir at 1500rpm for 15min;

[0045] (3) After mixing evenly, slowly put 3.4 kg of adhesive emulsion into the reaction kettle and stir for 10 minutes;

[0046] (4) Put 27.09 kg of the first heat-resistant ceramic (alumina whisker) and 11.61 kg of the second heat-resistant ceramic (aluminum nitride particles) into the reaction kettle, and stir at 1500rpm for 0.5h;

[0047] (5) Add 0.1 kg of thickener into the reaction kettle, and stir for 1 hour at 1500 rpm;

[0048] (6) After the slurry is mixed evenly, weigh and pack.

Embodiment 3-7

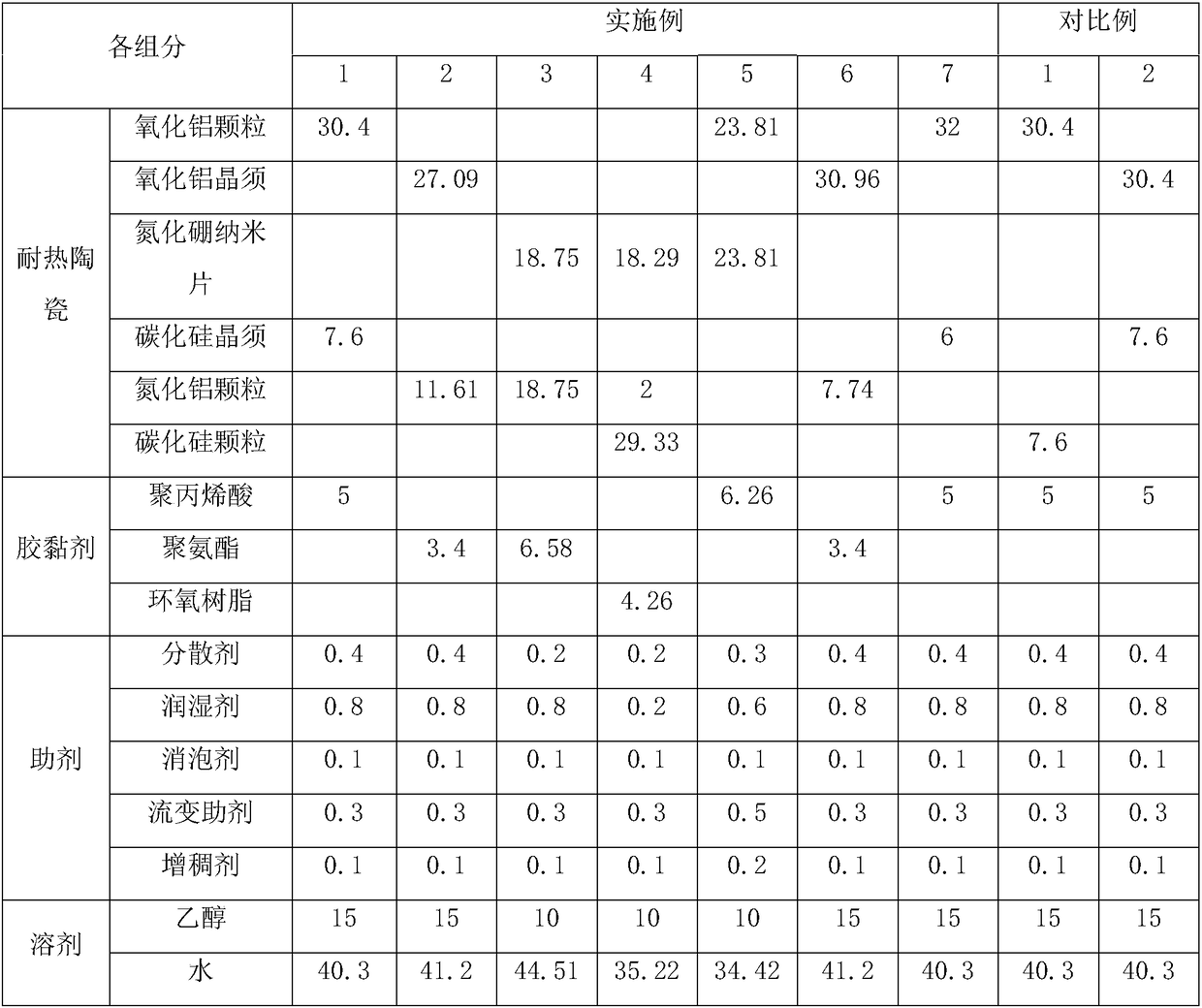

[0050] Examples 3-7 respectively provide a slurry for lithium-ion battery separators, and the specific components and contents are shown in Table 1; the preparation method is the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com