Method for preparing high-activity light calcined magnesia through suspending-boiling multi-flow-state combined mode

A light-burned magnesia, high-activity technology, applied in the field of metallurgy, can solve the problems of insufficient heat transfer and reaction time, high labor intensity, incomplete material decomposition, etc., to improve resource utilization, improve the working environment, and avoid flying losses Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

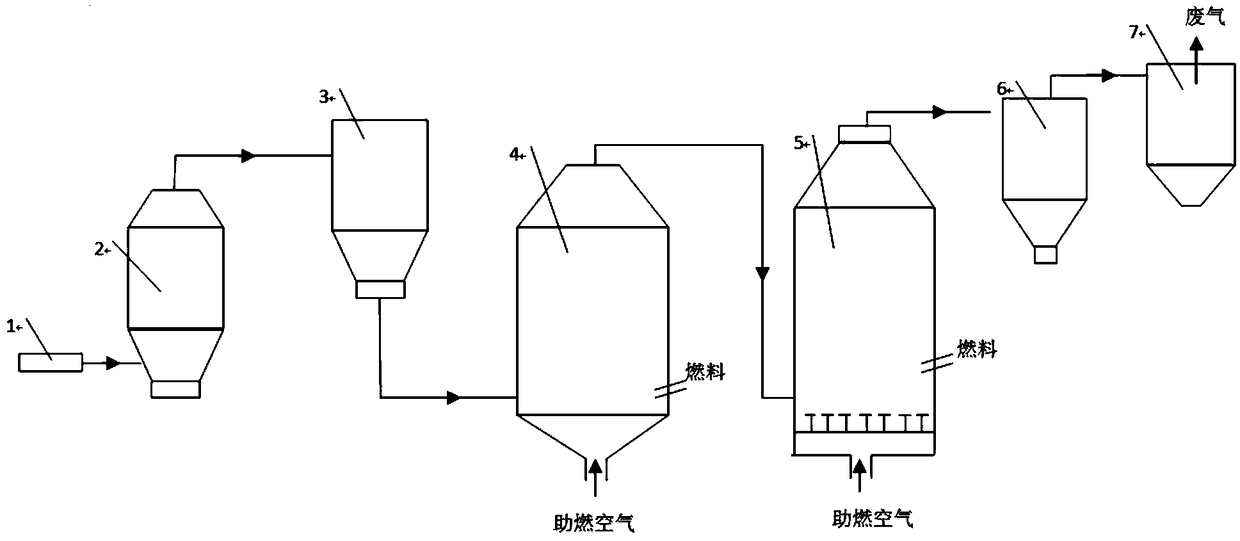

[0023] Suspension-boiling multi-fluid combination method for preparing high-activity light-burned magnesia, the specific steps are as follows:

[0024] (1) The magnesite raw material with a particle size of 0-2 mm is sent to the drying system Venturi dryer 2 through the screw conveyor 1 of the feeding system for drying, and the magnesite raw material is heated to 100-200 °C in 1-5 sec.;

[0025] (2) The dried material is sent to the preheating system 3 for preheating through the connecting pipeline. The preheating system can be a one-stage to five-stage cyclone preheater, and the temperature of the material is raised to 400-700 °C in 1-20 sec.;

[0026] (3) The preheated magnesite enters the suspension roasting and decomposition furnace 4 through the pipeline, and the temperature in the suspension roasting and decomposition furnace is 600-1000°C. Under the action of hot air flow, magnesite particles are suspended in the roasting furnace, and the fuel is fed from the burner at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com