Impurity removing device for rolling lithium-ion battery diaphragm

A lithium-ion battery and winding device technology, which is applied to winding strips, transportation and packaging, cleaning methods and appliances, etc., can solve the problems of automatic replacement of winding drums, easy contamination of the surface of the diaphragm, and affecting the effect of winding, etc. problems, to achieve the effect of high efficiency of impurity removal, easy production and maintenance, and fast cleaning speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 with Figure 9 , the present invention provides a technical solution:

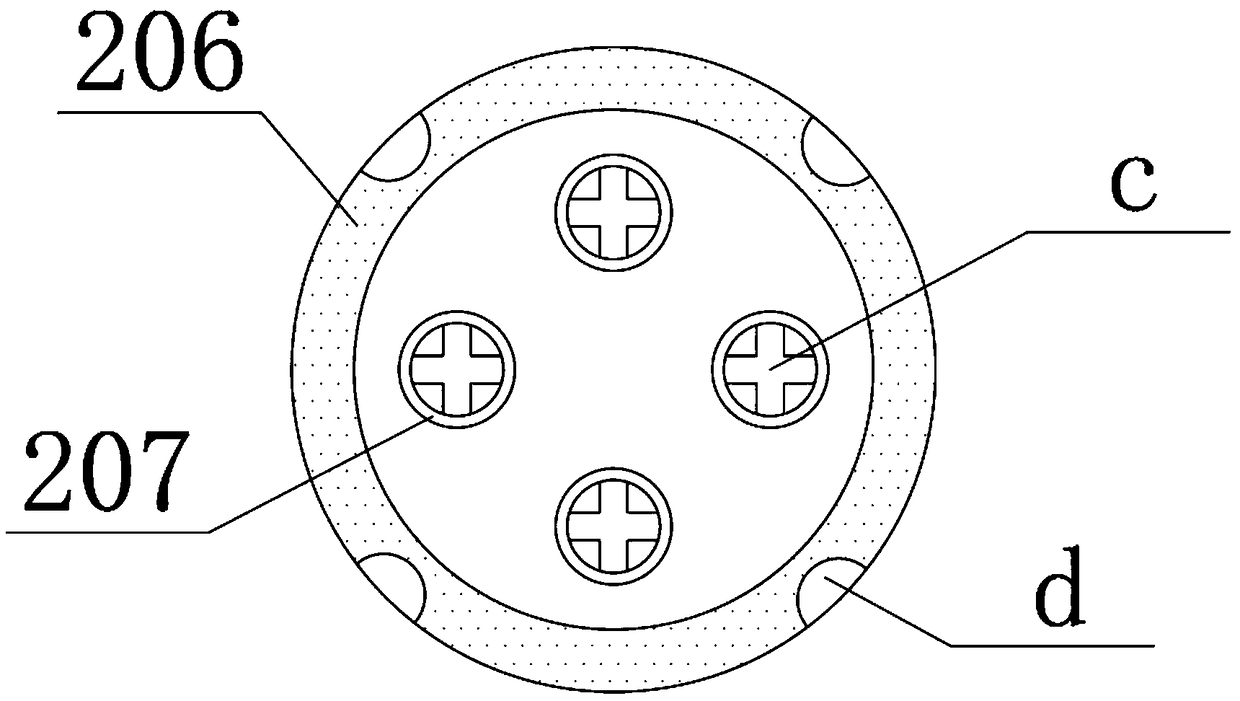

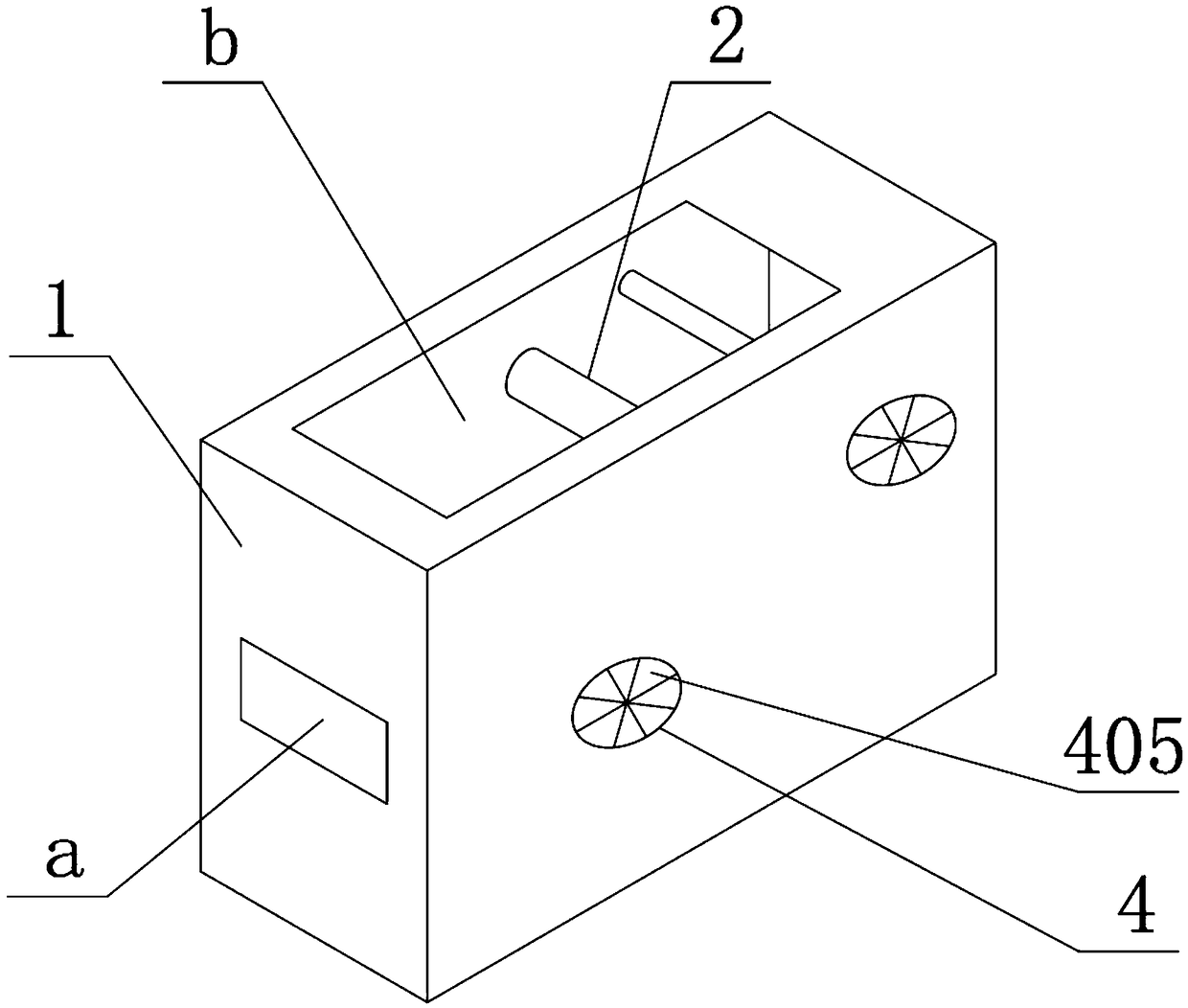

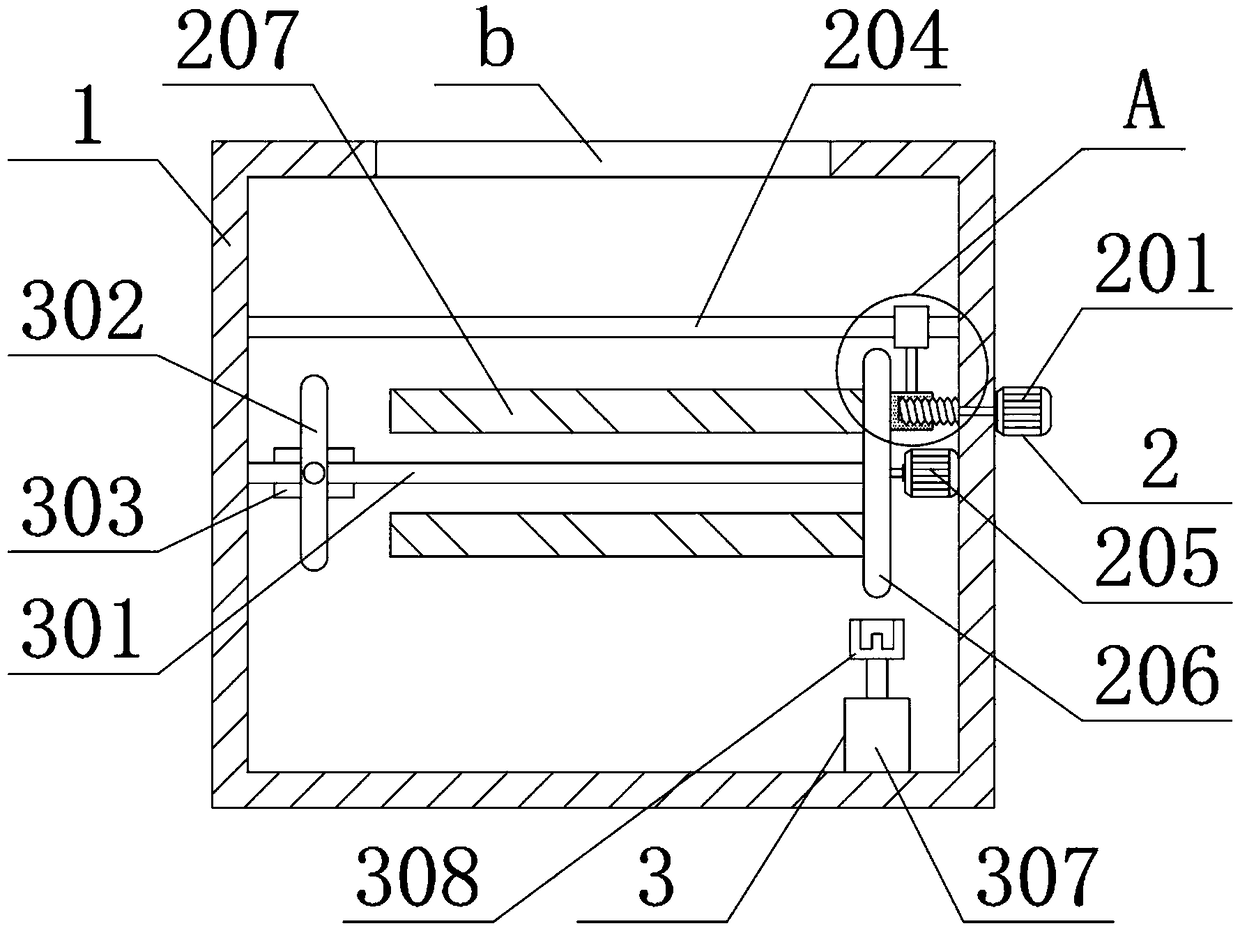

[0031] A kind of impurity removal device for lithium-ion battery diaphragm winding, comprising a casing 1, a winding device 2, a fixing device 3 and a removal device 4, the inner right end surface of the casing 1 is provided with a winding device 2, and the winding device 2 Including three-phase motor 201, screw rod 202 and movable frame 208, the right end of casing 1 is fixedly connected with three-phase motor 201, the main shaft end of three-phase motor 201 is fixedly connected with screw rod 202, and the outside of screw rod 202 is provided with movable frame 208, movable frame The inner side of 208 is provided with threads, and the movable frame 208 is spirally connected with the screw rod 202 through the set threads, and the screw rod 202 is arranged on the inner right end surface of the casing 1, making the operation ...

Embodiment 2

[0035] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 with Figure 9 , the present invention provides a technical solution:

[0036] A kind of impurity removal device for lithium-ion battery diaphragm winding, comprising a casing 1, a winding device 2, a fixing device 3 and a removal device 4, the inner right end surface of the casing 1 is provided with a winding device 2, and the winding device 2 Including three-phase motor 201, screw rod 202 and movable frame 208, the right end of casing 1 is fixedly connected with three-phase motor 201, the main shaft end of three-phase motor 201 is fixedly connected with screw rod 202, and the outside of screw rod 202 is provided with movable frame 208, movable frame The inner side of 208 is provided with threads, and the movable frame 208 is spirally connected with the screw rod 202 through the set threads, and the screw rod 202 is arranged on the inner right end surface of the casin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com