Collecting and purifying system for deckle edges and paper powder

A paper edge collection and purification system technology, which is applied in the field of paper edge and paper powder collection and purification systems, can solve problems such as air pollution and drift, and achieve the effect of eliminating dust and facilitating treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described with reference to the accompanying drawings.

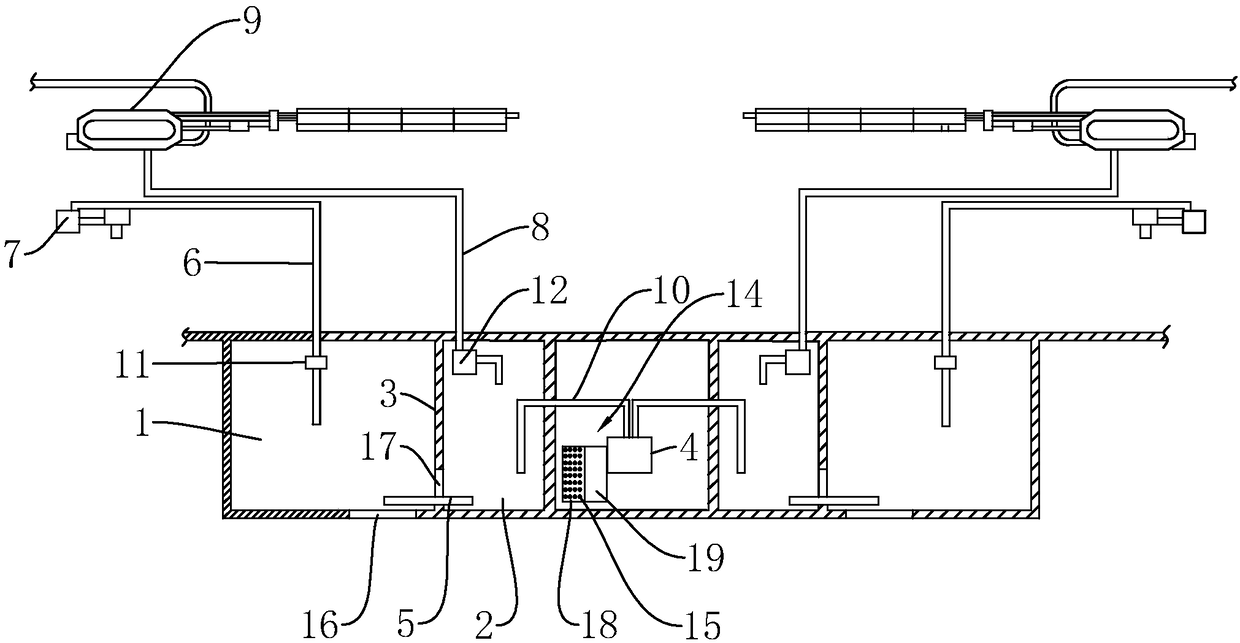

[0028] This embodiment discloses a collection and purification system for paper edges and paper dust, such as figure 1 As shown, it includes a paper edge collection room 1 and a paper powder collection room 2 built outdoors, and the paper edge collection room 1 and the paper powder collection room 2 are formed by a large room separated by a partition wall 3 . The side of the paper powder collection room 2 away from the paper edge collection room 1 is equipped with a dust removal fan 4 outdoors, and the opposite sides of the dust removal fan 4 are symmetrically equipped with a paper edge collection room 1 and a paper powder collection room 2

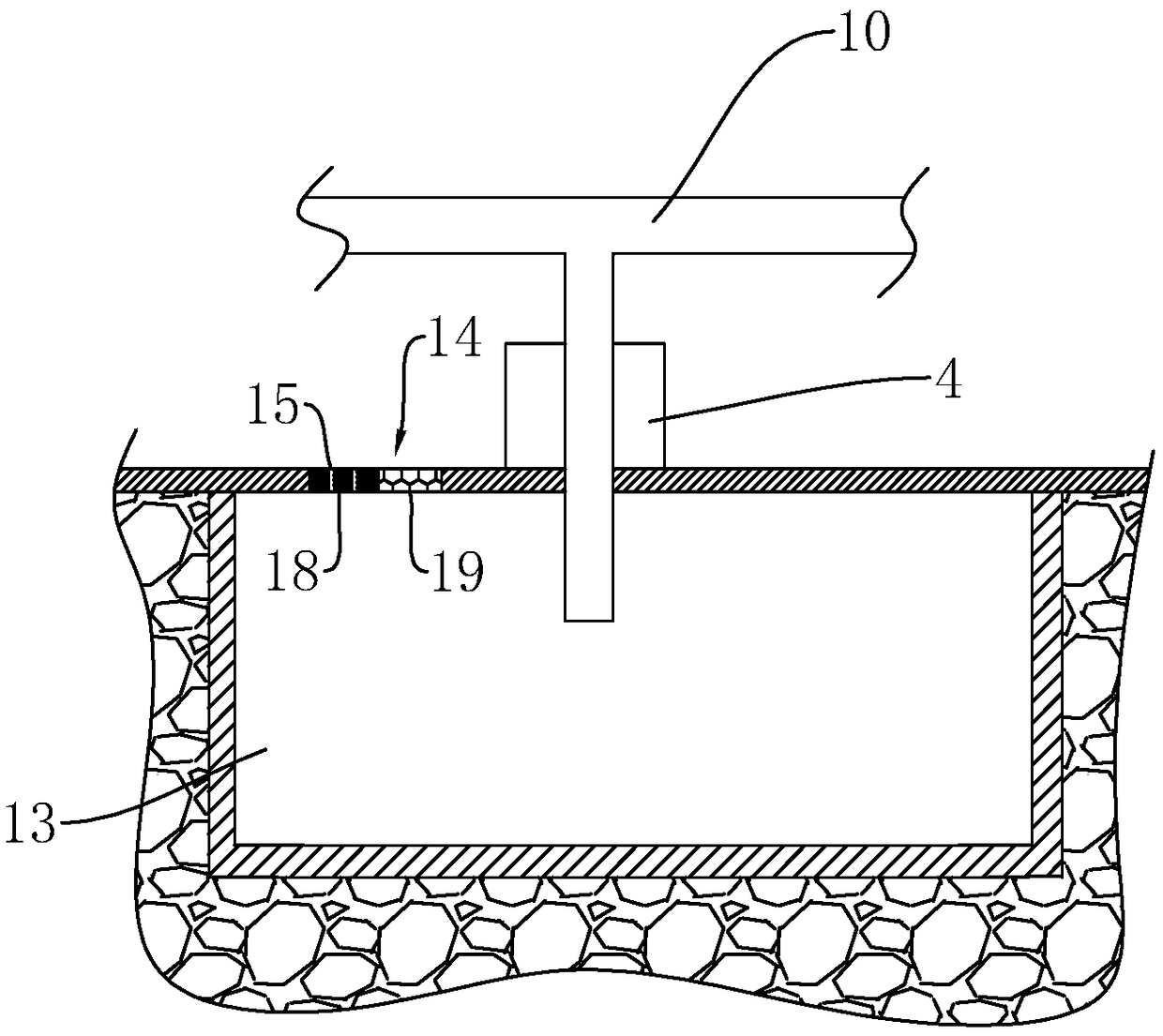

[0029] Such as figure 1 , 2 As shown, the upper end of the partition wall 3 is equipped with a suction pipe 5 communicating with the paper powder collection room 2 and the paper edge collection room 1 . The paper edge collection room 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com