Machine room equipment radiating device for directly radiating to outside of machine room

A technology for cooling devices and computer rooms, which is applied in lighting and heating equipment, household heating, heating methods, etc. The effect of reducing dust and reducing power consumption of air conditioners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

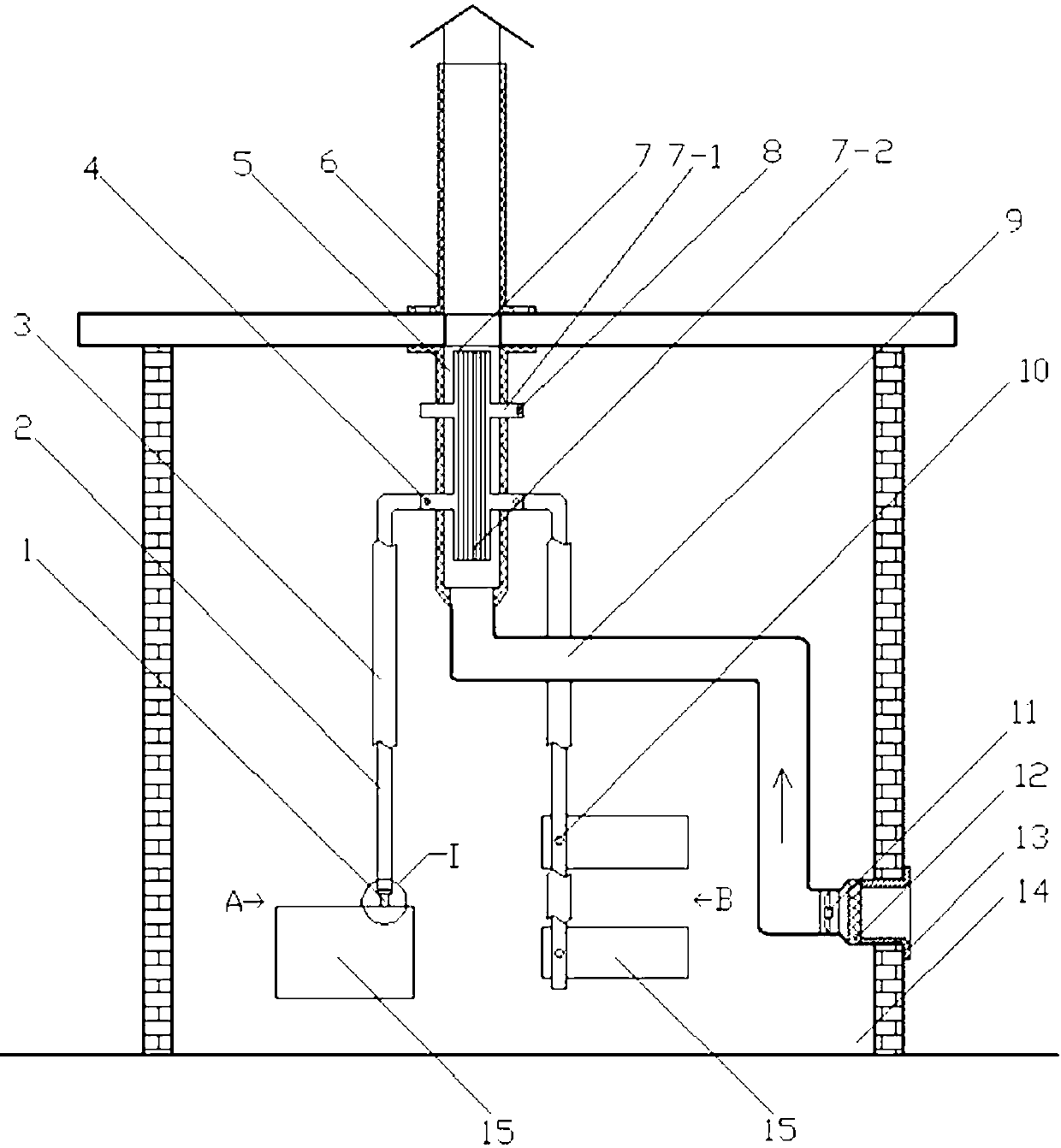

[0027] Depend on Figure 1-6 As can be seen from the shown embodiment, it includes a heat exhaust chimney 6, a heat collecting radiator 7 and a chamber 5 thereof, a heat conduction strip 2, a heat collection column 1, a temperature sensor 8, a temperature control fan 11 and an air duct 9 thereof and an anti- Dust net 12 and its support 13;

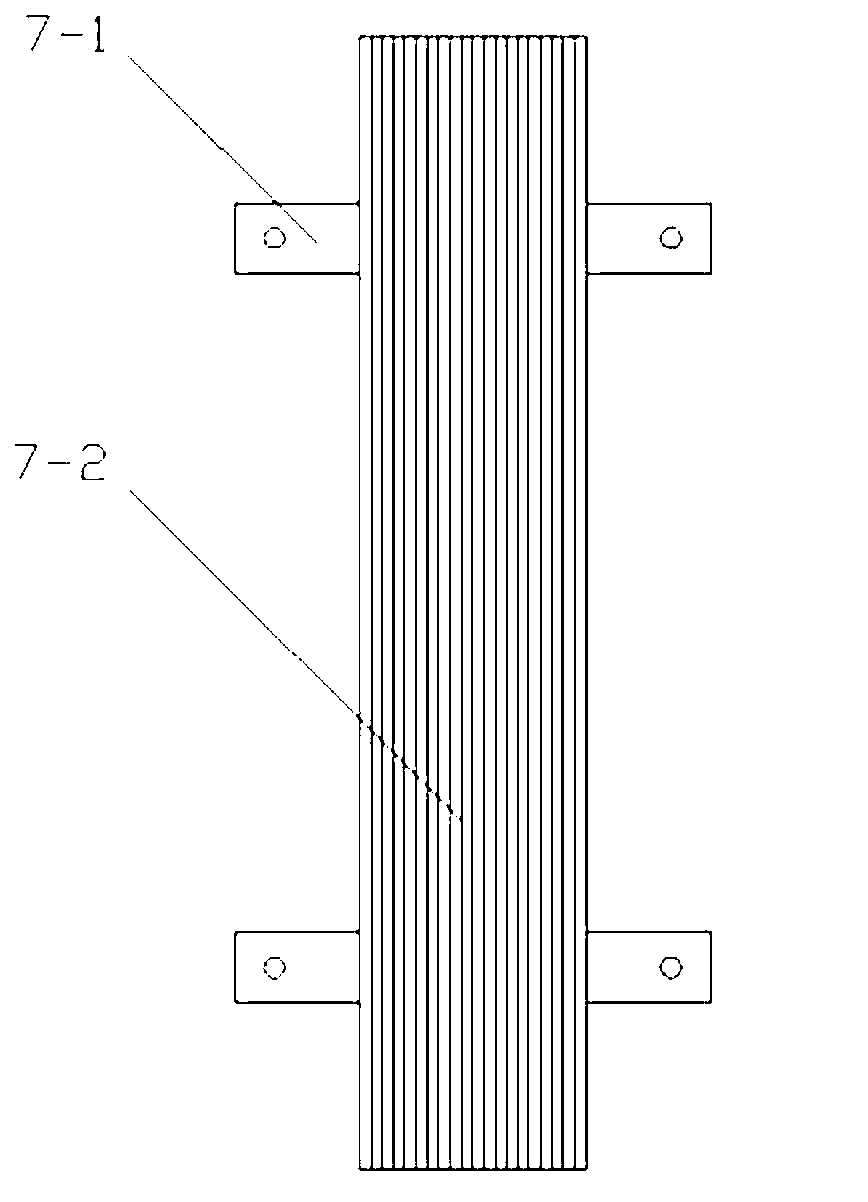

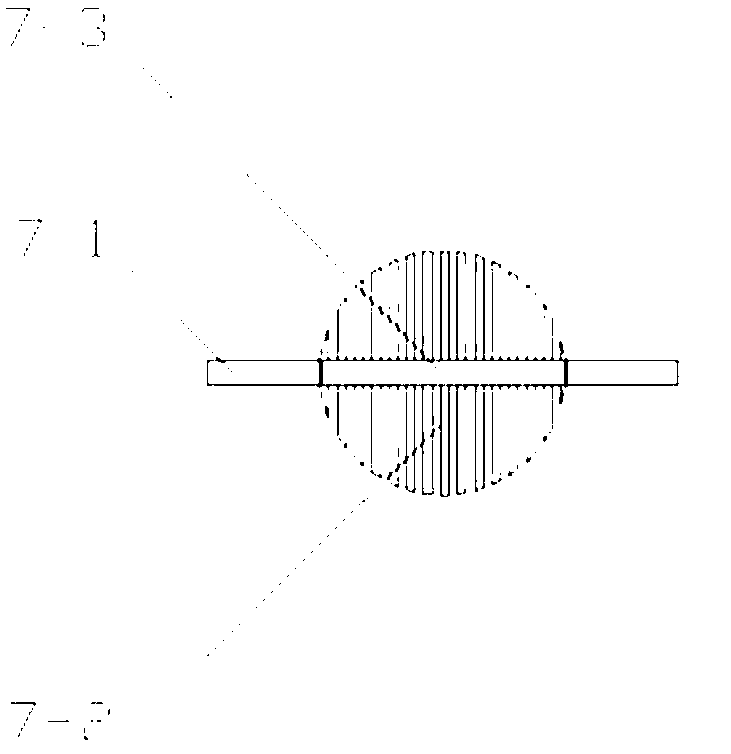

[0028] The heat collecting radiator 7 is made up of a heat collecting plate 7-3, a cooling fin 7-2 and more than 2 lugs 7-1 (the number of lugs depends on the quantity and distribution of equipment in the machine room, such as figure 1 Only two lugs are used, and other unused lugs are covered with heat-insulating sleeves); the heat collecting plate 7-3 is a rectangular plate made of heat-conducting material, and the cooling fins 7-2 are symmetrically distributed on the collecting On both sides of the heat plate 7-3, the lugs 7-1 are located on the two sides of the heat collecting plate 7-3 (see figure 2 and image 3 );

[0029] The he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com