Preparation method of core-shell structure CuCl/Cu nano rod material

A core-shell structure and nanorod technology is applied in the field of preparation of CuCl/Cu nanorod materials, which can solve the problems of high cost of raw materials, high reaction temperature, corrosion of equipment, etc., and achieve the effects of low cost, simple preparation and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Add 100mg of copper nanorods into 20mL of absolute ethanol, ultrasonically for 0.5h, and disperse evenly.

[0023] (2) Add the solution into a suction filter, vacuum filter, and attach the copper nanorods to the surface of the nylon filter membrane.

[0024] (3) Add 134.45 mg of copper chloride dihydrate powder into 10 mL of ethanol, stir for 2 minutes, and prepare a 0.1 mol / L copper chloride ethanol solution.

[0025] (4) Add 10 mL of 0.1 mol / L copper chloride aqueous solution into the suction filter, and quickly drain the solution.

[0026] (5) Dry the nylon film in an oven at a temperature of 60° C. for 5 minutes.

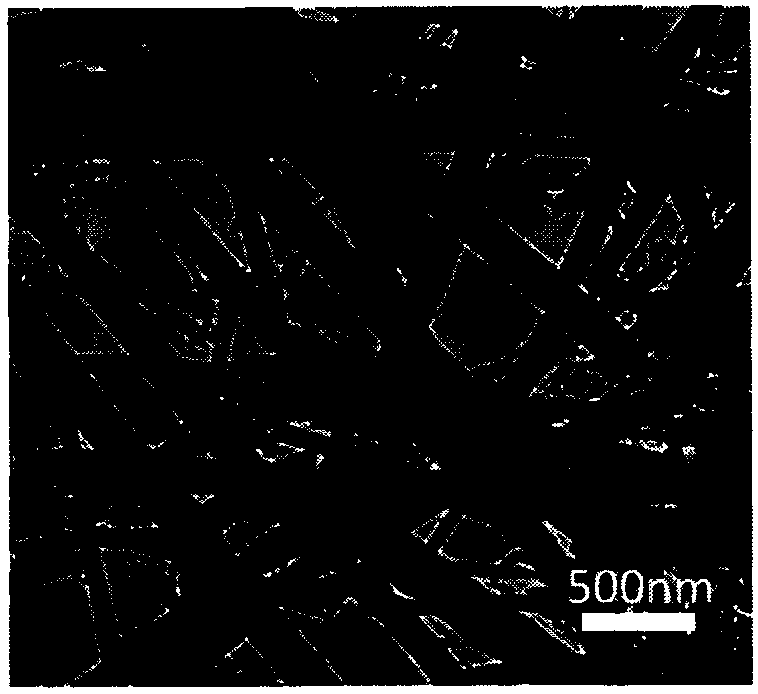

[0027] figure 1 The transmission electron microscope images of CuCl / Cu nanorod materials with core-shell structure were prepared for this example.

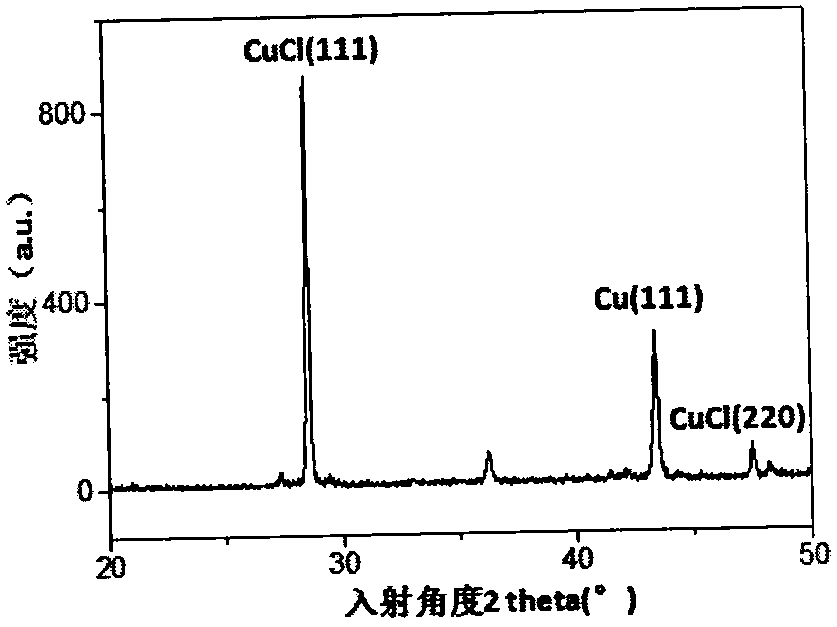

[0028] figure 2 The X-ray diffraction pattern of the core-shell structure CuCl / Cu nanorod material was prepared for this example.

Embodiment 2

[0030] (1) Add 100mg of copper nanorods into 20mL of absolute ethanol, ultrasonically for 0.5h, and disperse evenly.

[0031] (2) Add the solution into a suction filter, vacuum filter, and attach the copper nanorods to the surface of the polyvinylidene fluoride filter membrane.

[0032] (3) Add 134.45 mg of copper chloride dihydrate powder into 10 mL of ethanol, stir for 2 minutes, and prepare a 0.1 mol / L copper chloride ethanol solution.

[0033] (4) Add 10 mL of 0.1 mol / L copper chloride aqueous solution into the suction filter, and quickly drain the solution.

[0034] (5) Dry the nylon film in an oven at a temperature of 60° C. for 5 minutes.

Embodiment 3

[0036] (1) Add 100mg of copper nanorods into 20mL of absolute ethanol, ultrasonically for 0.5h, and disperse evenly.

[0037] (2) Add the solution into a suction filter, vacuum filter, and attach the copper nanorods to the surface of the nylon filter membrane.

[0038] (3) Add 134.45 mg of copper chloride dihydrate powder into 20 mL of ethanol, stir for 2 minutes, and prepare a 0.05 mol / L copper chloride ethanol solution.

[0039] (4) Add 10 mL of 0.05 mol / L copper chloride aqueous solution into the suction filter, and quickly drain the solution.

[0040] (5) Dry the nylon film in an oven at a temperature of 60° C. for 5 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com