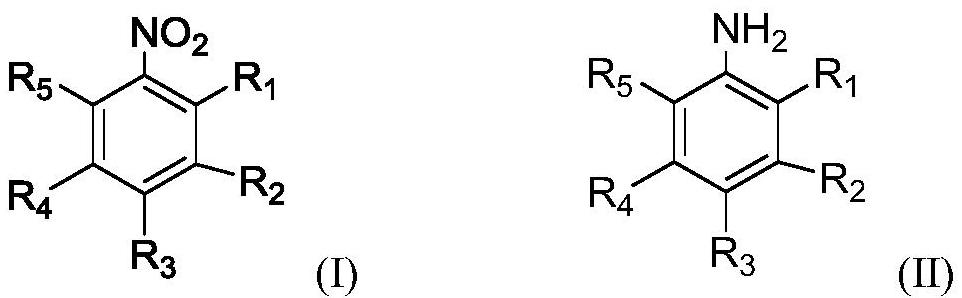

Preparation of a sulfur-doped activated carbon-supported noble metal catalyst and its application in hydrogenation of halogenated aromatic nitro compounds

A precious metal catalyst, hydrogenation reaction technology, applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, preparation of amino compounds, etc., can solve the problems of poor stability, poor selectivity and high activity, Achieve the effect of delayed life, low cost and low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Weigh Na 2 S·9H 2 O 1.4981g, add deionized water to make 50mL solution, mix well with 10g activated carbon, hydrothermally treat in a high-pressure hydrothermal reactor at 180°C for 10h; filter after cooling to room temperature, wash with a large amount of deionized water until the filtrate is neutral , The resulting filter cake was vacuum-dried at 110°C for 12 hours to obtain sulfur-doped activated carbon. Then 2.5g of the above-mentioned sulfur-doped activated carbon was made into a slurry with deionized water at a ratio of 1:3, and 0.5mL of H 2 PdCl 4 solution (Pd content is 0.05g / mL), stirred for 30min; then added 0.5mL sodium acetate solution (0.1g / mL), stirred for 30min; adjusted the pH value of the solution to 7-9 with 0.1g / mL NaOH solution, and continued to stir 30min; slowly add 0.5mL formaldehyde solution (37%-40%) dropwise, and continue to stir for 30min; filter, wash the filter cake with deionized water, and vacuum dry the filter cake at 110°C for 12h to ...

Embodiment 2

[0034] Weigh Na 2 S·9H 2 O 3.8216g, add 50mL deionized water to make a solution, mix with 10g activated carbon evenly, and hydrothermally treat in a high-pressure hydrothermal reactor at 200°C for 24h; filter after cooling to room temperature, wash with a large amount of deionized water until the filtrate is neutral , The resulting filter cake was vacuum-dried at 110°C for 12 hours to obtain sulfur-doped activated carbon. Then 2.5 g of the above-mentioned sulfur-doped activated carbon was made into a slurry with deionized water at a ratio of 1:5, and 1 mL of H 2 PdCl 4 Solution (Pd content is 0.05g / mL), stir for 100min; then add 1.5mL sodium acetate solution (0.1g / mL), stir for 100min; use 0.1g / mL KOH solution to adjust the pH value of the solution to 7-9, continue to stir 100 min; slowly add 1 mL of formaldehyde solution dropwise, and continue to stir for 100 min; filter, wash the filter cake with deionized water, and vacuum dry the filter cake at 110°C for 12 h to obtain ...

Embodiment 3

[0036] Weigh Na 2 S·9H 2O 7.4934g, add 100mL of deionized water to make a solution, mix well with 10g of activated carbon, hydrothermally treat in a high-pressure hydrothermal reactor at 250°C for 36h; filter after cooling to room temperature, wash with a large amount of deionized water until the filtrate is neutral , The resulting filter cake was vacuum-dried at 110°C for 12 hours to obtain sulfur-doped activated carbon. Then 2.5g of the above-mentioned sulfur-doped activated carbon was made into a slurry with deionized water at a ratio of 1:10, and 2.5mL of H 2 PdCl 4 Solution (Pd content is 0.05g / mL), stir for 60min; then add 2.5mL sodium acetate solution (0.1g / mL), stir for 60min; use 0.1g / mL NaOH solution to adjust the pH value of the solution to 7-9, continue to stir 60min; slowly add 0.6mL formaldehyde solution (37%-40%) dropwise, and continue to stir for 60min; filter, wash the filter cake with deionized water, and vacuum dry the filter cake at 80°C for 24h to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com