Sleeve for covering a temperature sensor, temperature measuring device comprising said type of sleeve, method for joining said type of sleeve to a temperature measuring device and use of an alloy

A technology of temperature sensor and temperature measuring device, applied in the field of cover sensor, can solve the problems of low heat resistance, etc., and achieve the effects of good heat resistance, good corrosion resistance and good creep resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

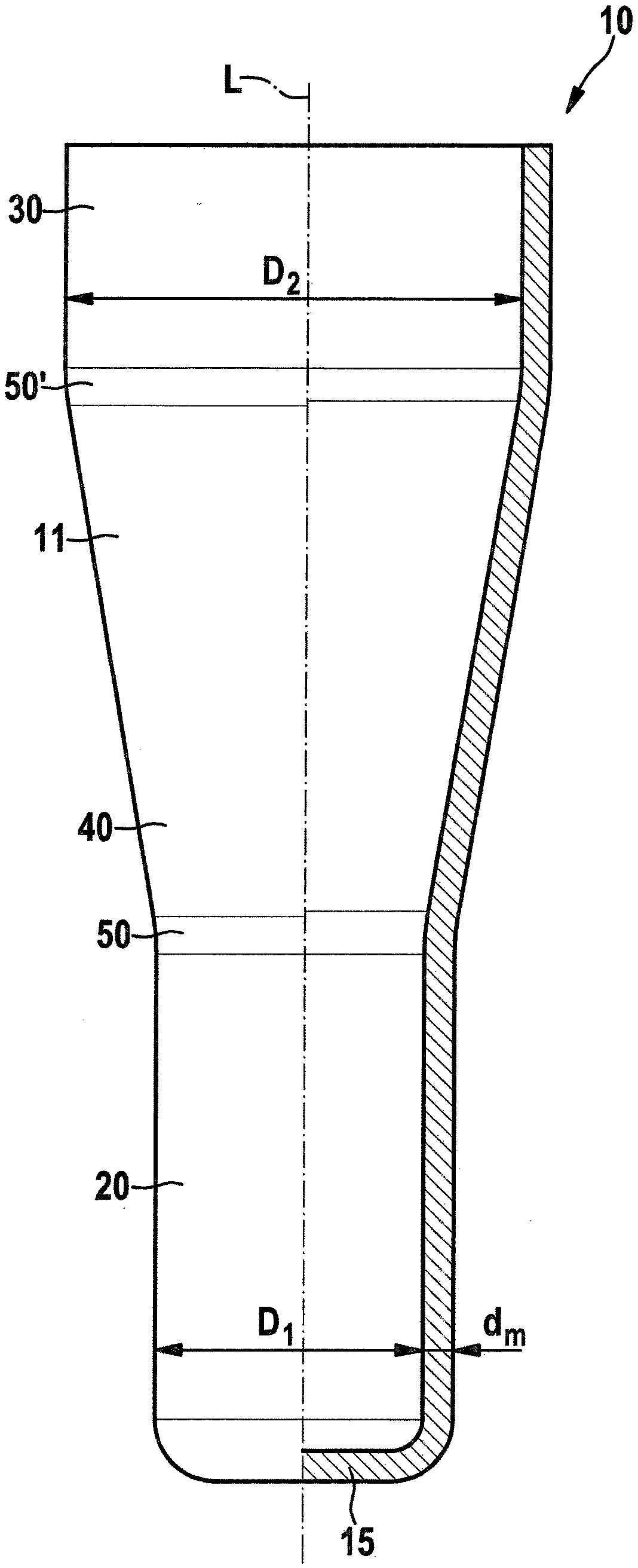

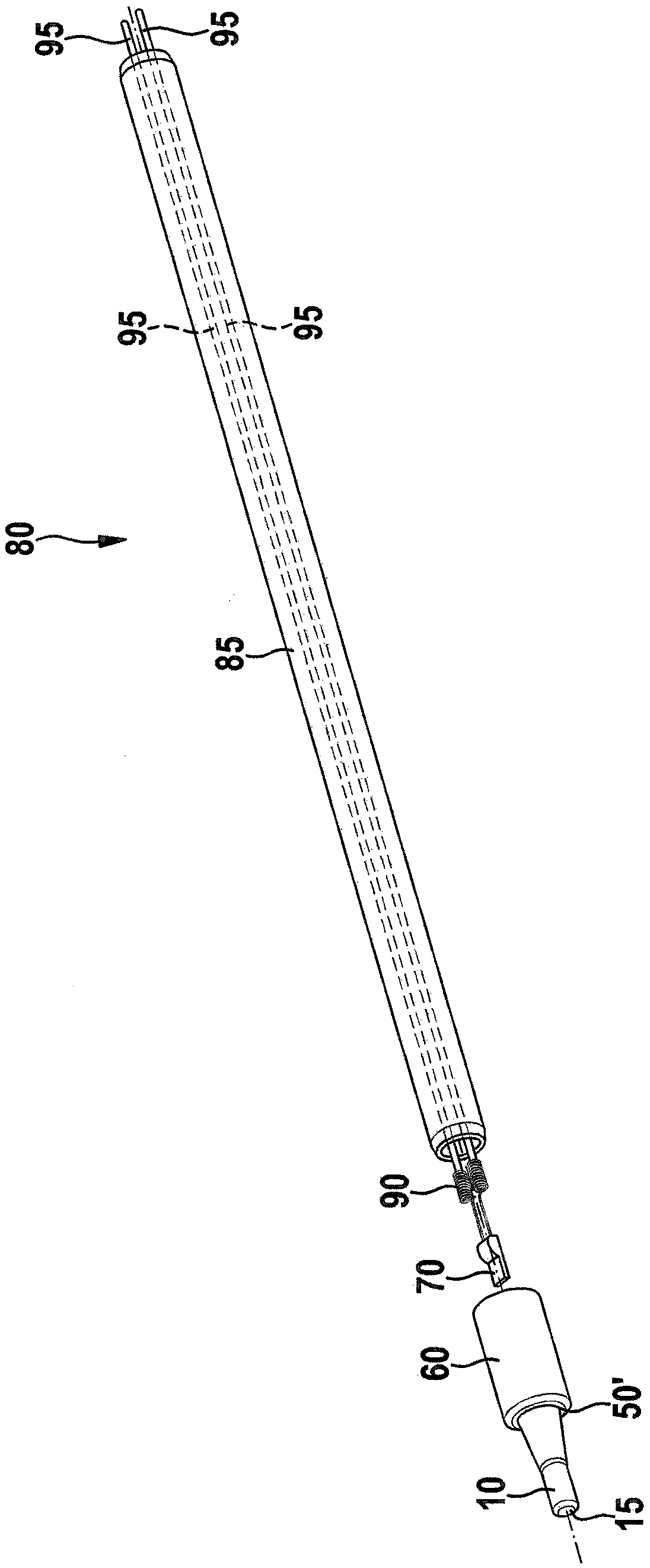

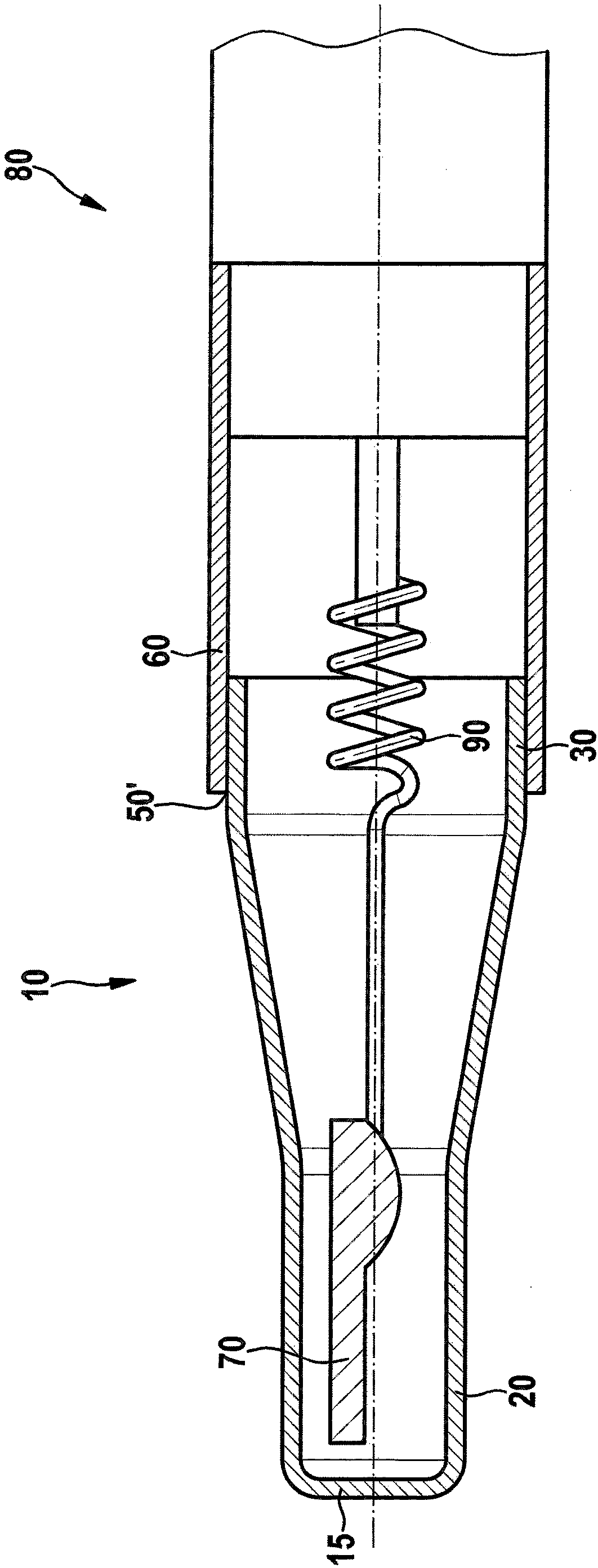

[0203] figure 1 A bushing 10 of the present invention is shown. The outer side 11 is shown in the left region of the illustration as viewed from the longitudinal axis L. As shown in FIG. A cross-section of the sleeve 10 is shown in the right-hand region of the illustration, viewed from the longitudinal axis L. FIG. It can be seen from the figure that the material thickness d M .

[0204] The bushing 10 according to the invention is a formed, in particular deep-drawn, component. Thus, the bushing 10 is formed in one piece, ie constructed in one piece. material thickness d shown M Preferably it is 0.22mm-0.28mm. In a particularly preferred embodiment, the material thickness d M Spreads evenly throughout the casing.

[0205] The bushing 10 of the present invention is composed of an alloy having

[0206] 24.3-26.3wt% chromium (Cr), especially 25.3wt% chromium (Cr),

[0207] 2.1-2.4wt% aluminum (Al), especially 2.27wt% aluminum (Al),

[0208] 9.0-10.5wt% iron (Fe), espec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com