A laser radiator with multiple cooling functions

A technology of multiple heat dissipation and lasers, applied in lasers, laser parts, semiconductor lasers, etc., can solve the problems of poor heat dissipation effect, single heat dissipation method of laser radiator, and inconvenient installation and use of the device, so as to increase the way of installation, Increase the cooling effect, easy to adjust the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing:

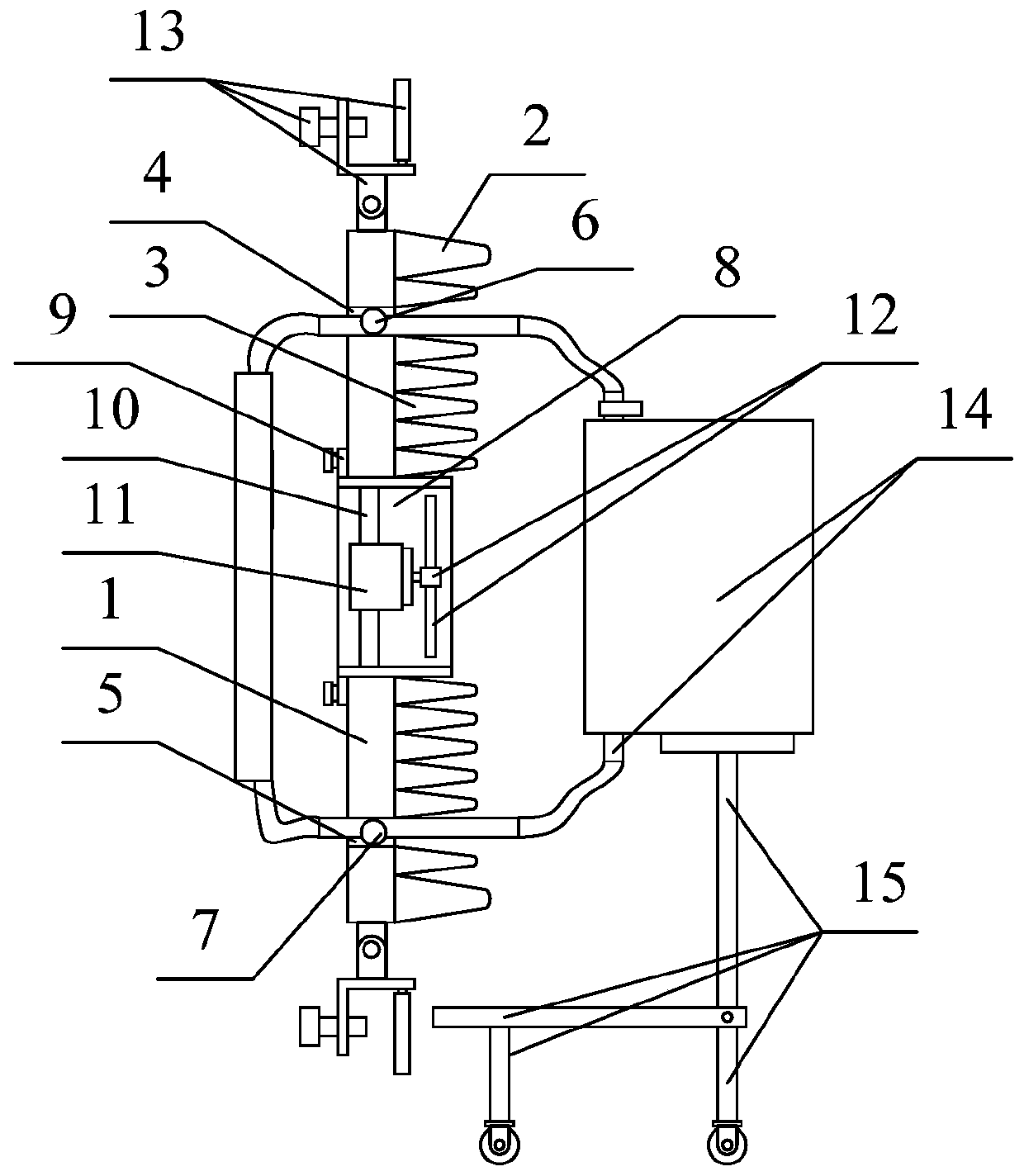

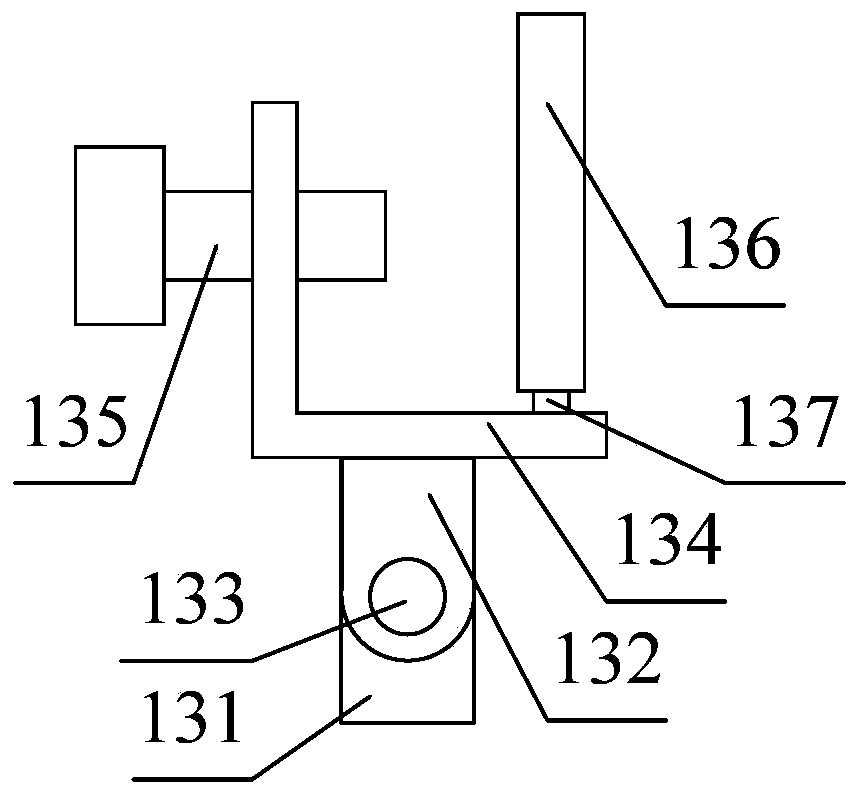

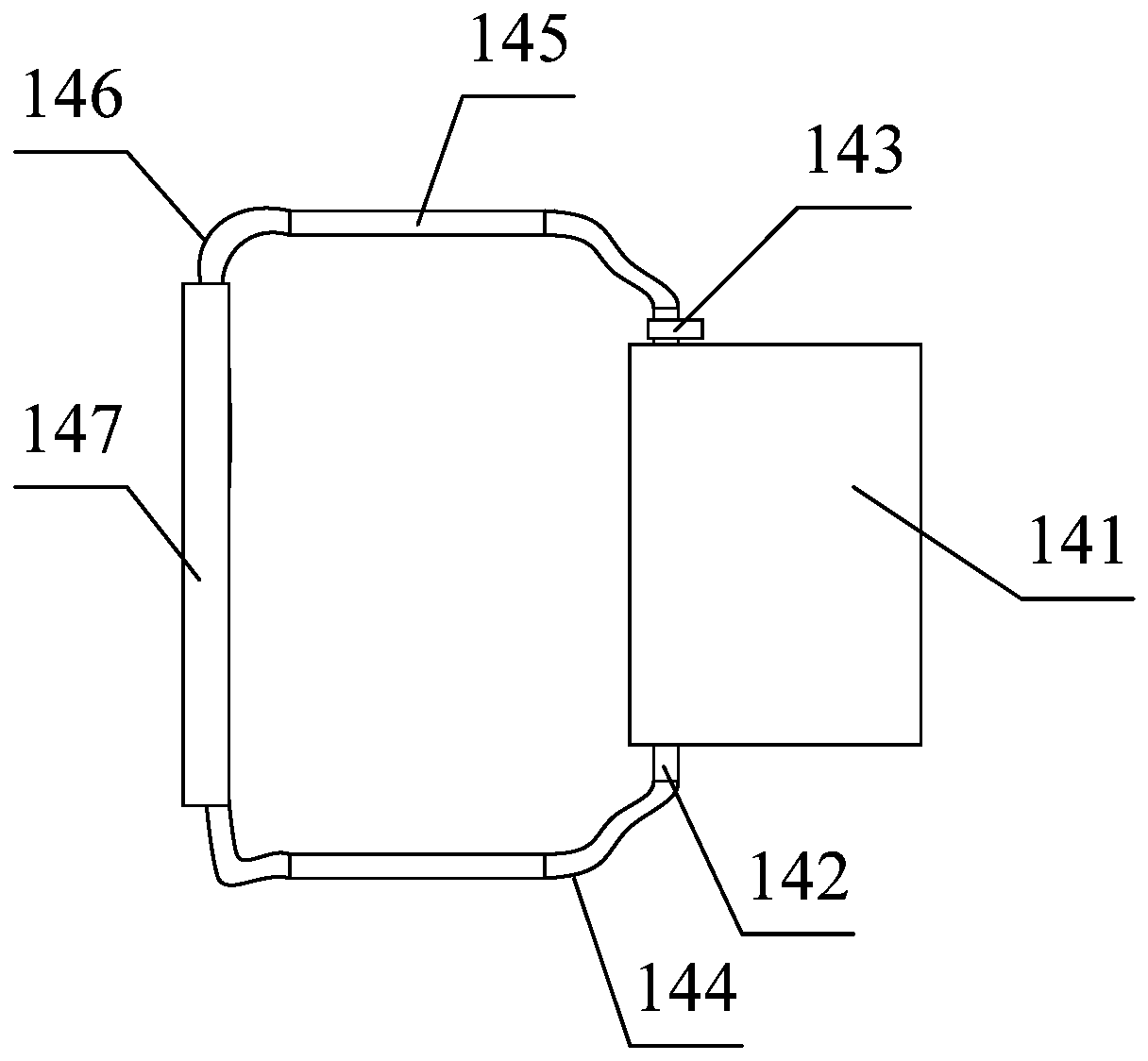

[0032] Such as figure 1 with figure 2As shown, a laser radiator with multiple heat dissipation functions according to the present invention includes a mounting sheet 1, a protective edge 2, a heat sink 3, a first insertion hole 4, a second insertion hole 5, and a first fastening bolt 6. The second fastening bolt 7, the connecting tube 8, the mounting edge 9, the vertical plate 10, the heat dissipation motor 11, the fan blade 12, the adjustable detachable splint structure 13, the adjustable water-cooling pipe box structure 14 and the detachable support and fixing frame Structure 15, the protective edge 2 is respectively welded on the upper and lower parts of the right surface of the mounting sheet 1; the heat sink 3 is welded on the right surface of the mounting sheet 1; the first insertion hole 4 and the second insertion hole Connecting holes 5 are provided on the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com