Display panel and package method thereof

A technology for display panels and packaging methods, which is applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., and can solve problems such as overflow of filling glue, collapse of sealing glue, short pre-curing time of sealing glue, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

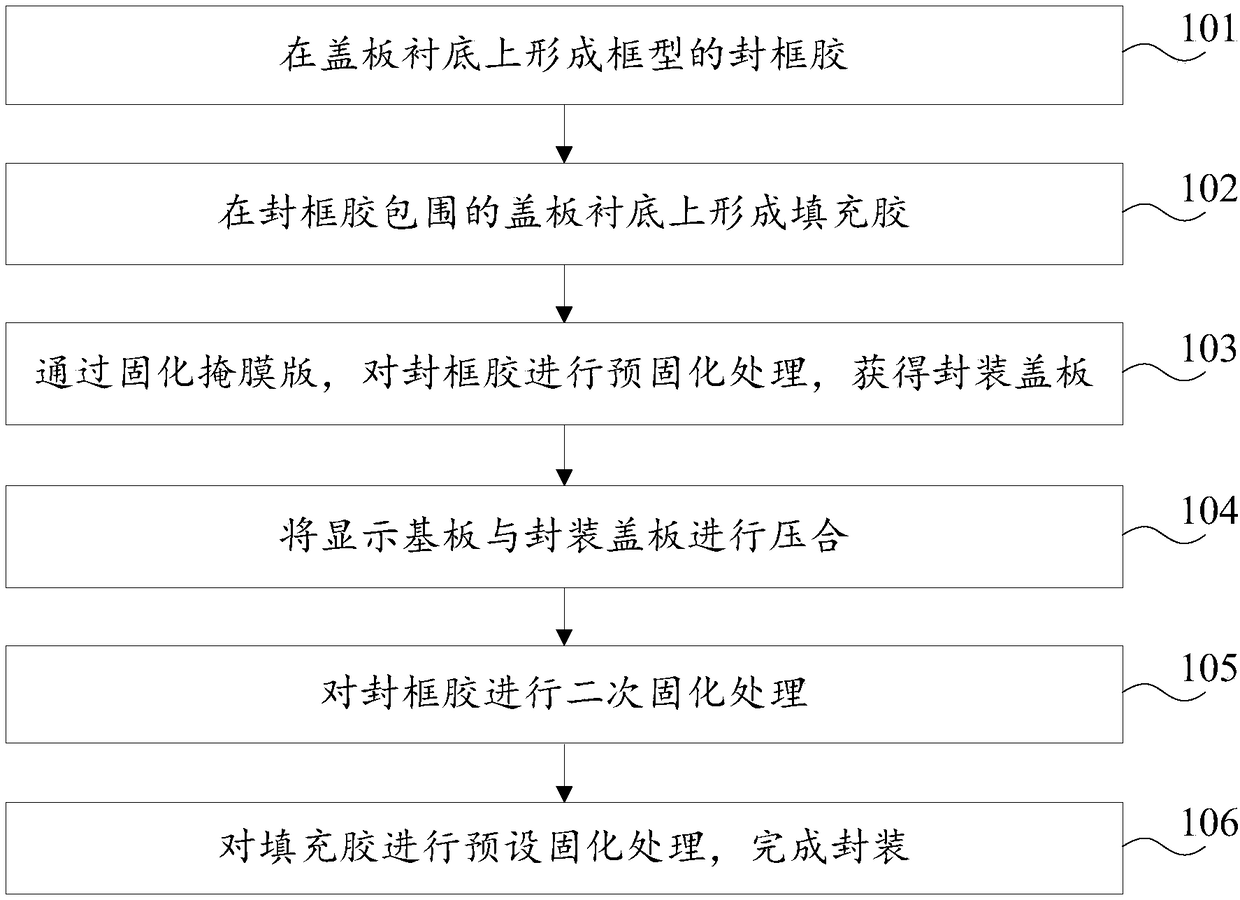

[0038] refer to figure 1 , shows a flow chart of steps of a display panel packaging method according to Embodiment 1 of the present invention.

[0039] The display panel packaging method of the embodiment of the present invention includes the following steps:

[0040] Step 101: forming a frame-shaped sealant on the cover substrate.

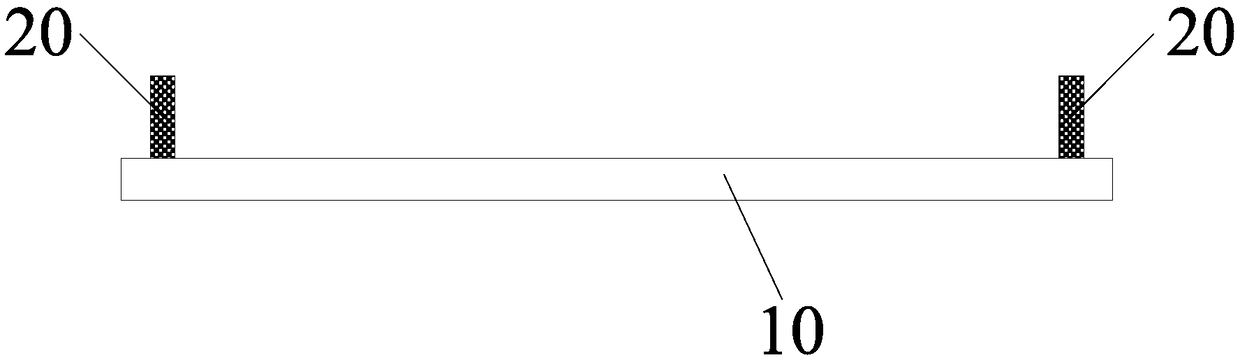

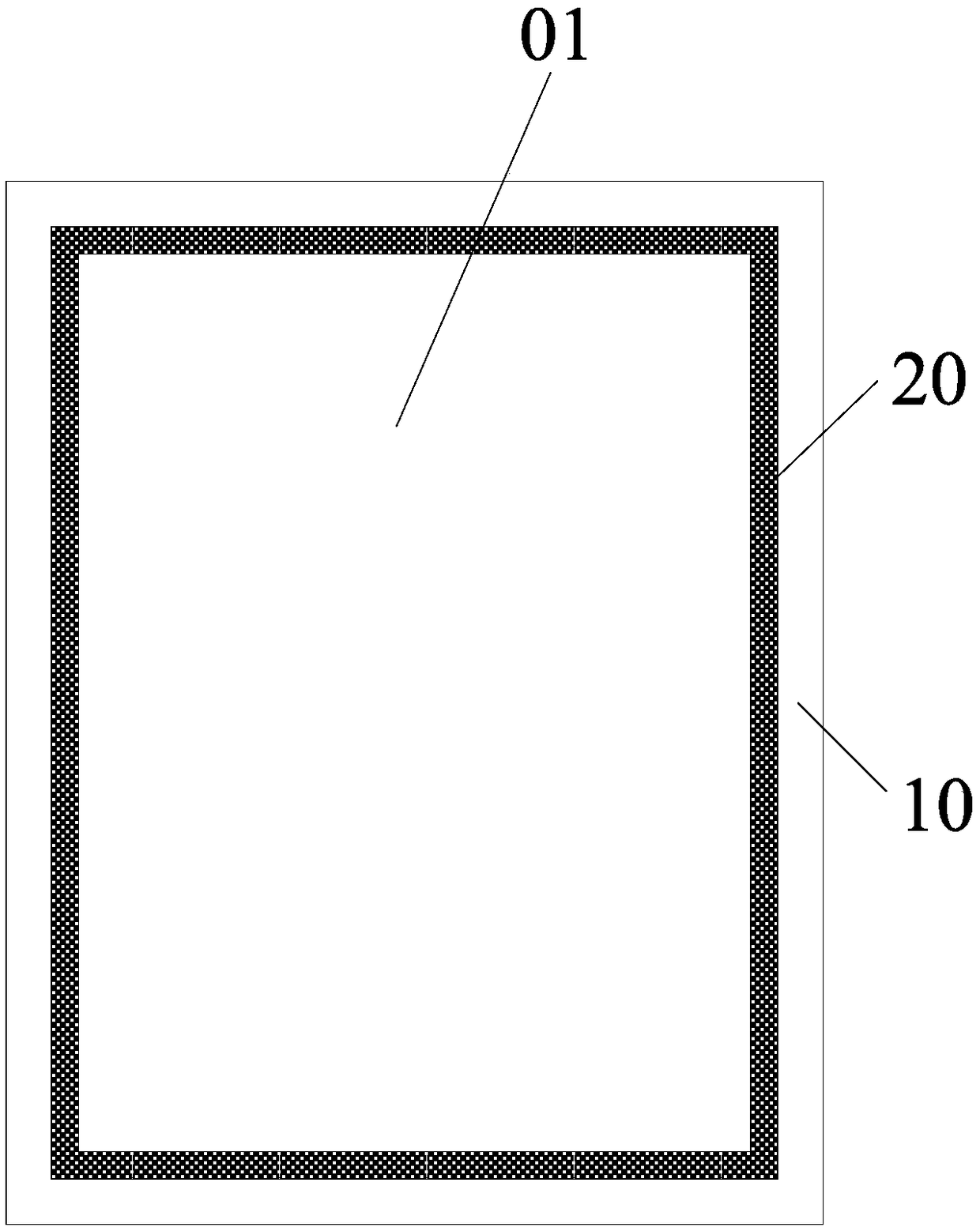

[0041] In the embodiment of the present invention, figure 2 It shows a schematic cross-sectional view of a packaging cover after forming a frame sealant, as shown in figure 2 As shown, first a cover substrate 10 may be provided, usually a glass substrate, and then a frame-shaped sealant 20 is formed on the cover substrate 10 . image 3 It shows a top view of the packaging cover plate after the frame sealant is formed, refer to image 3 The cover substrate area surrounded by the sealant 20 corresponds to the AA area (Active Area, effective display area) 01 in the display panel.

[0042] In a preferred embodiment, the material of the frame se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com