Train through passage sound insulation property testing method based on reverberation room and anechoic room

A testing method and a through-channel technology, which is applied to the analysis of solids, instruments, and analysis materials using sound waves/ultrasonic waves/infrasonic waves. The effect of outside interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0042] Such as Figure 2 to Figure 4 As shown, the present invention is based on reverberation chamber and anechoic chamber train passageway sound insulation performance test method comprises the following steps:

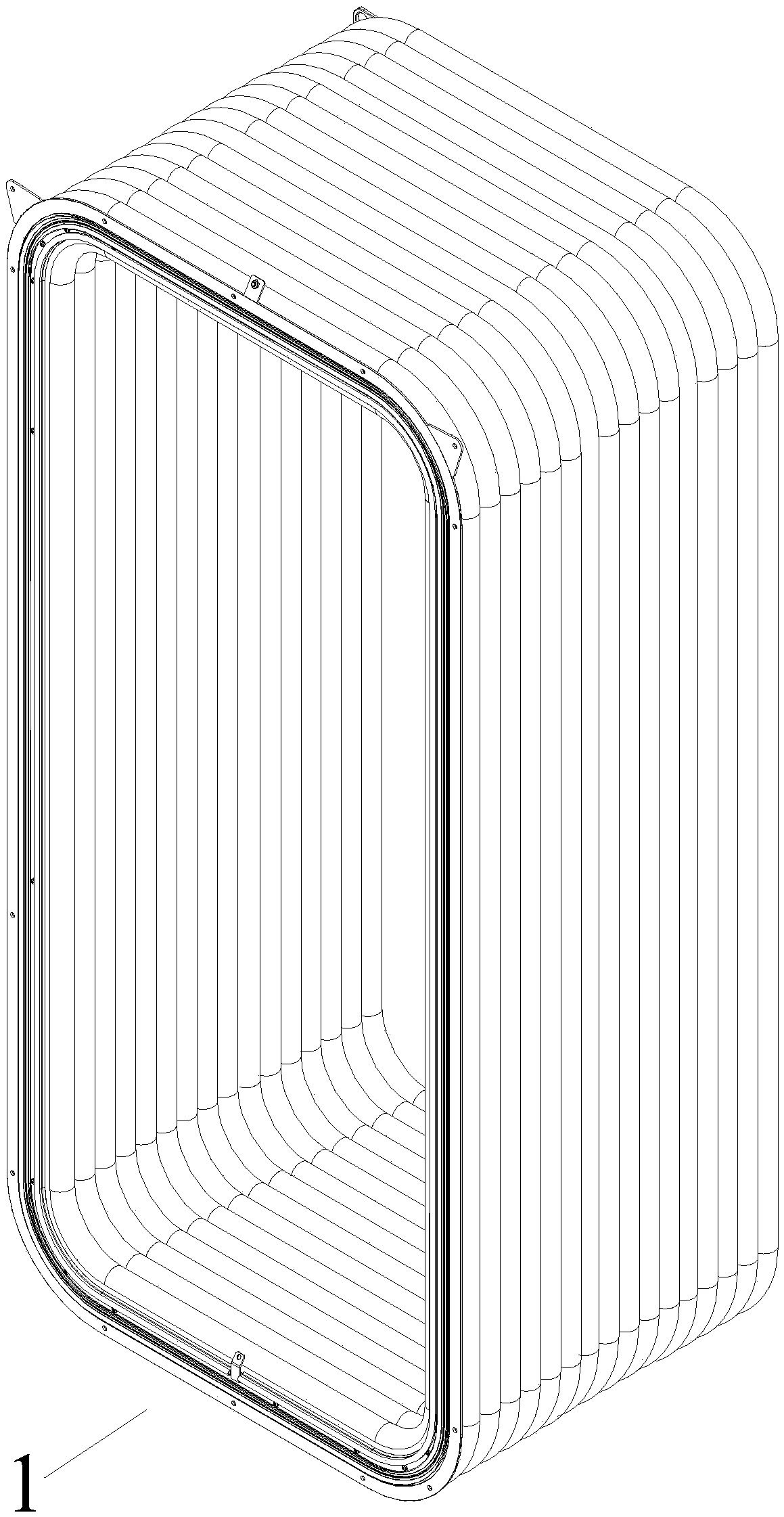

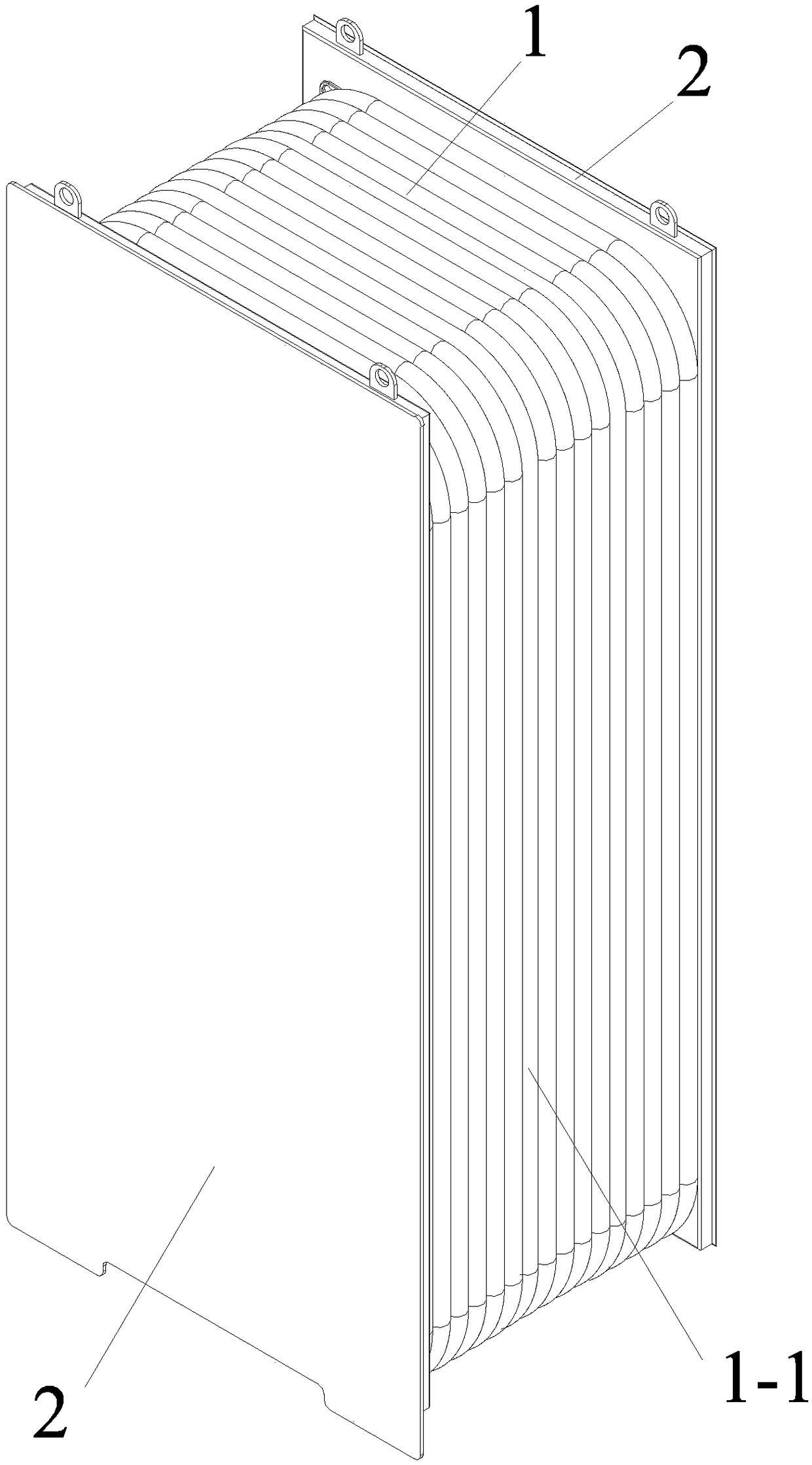

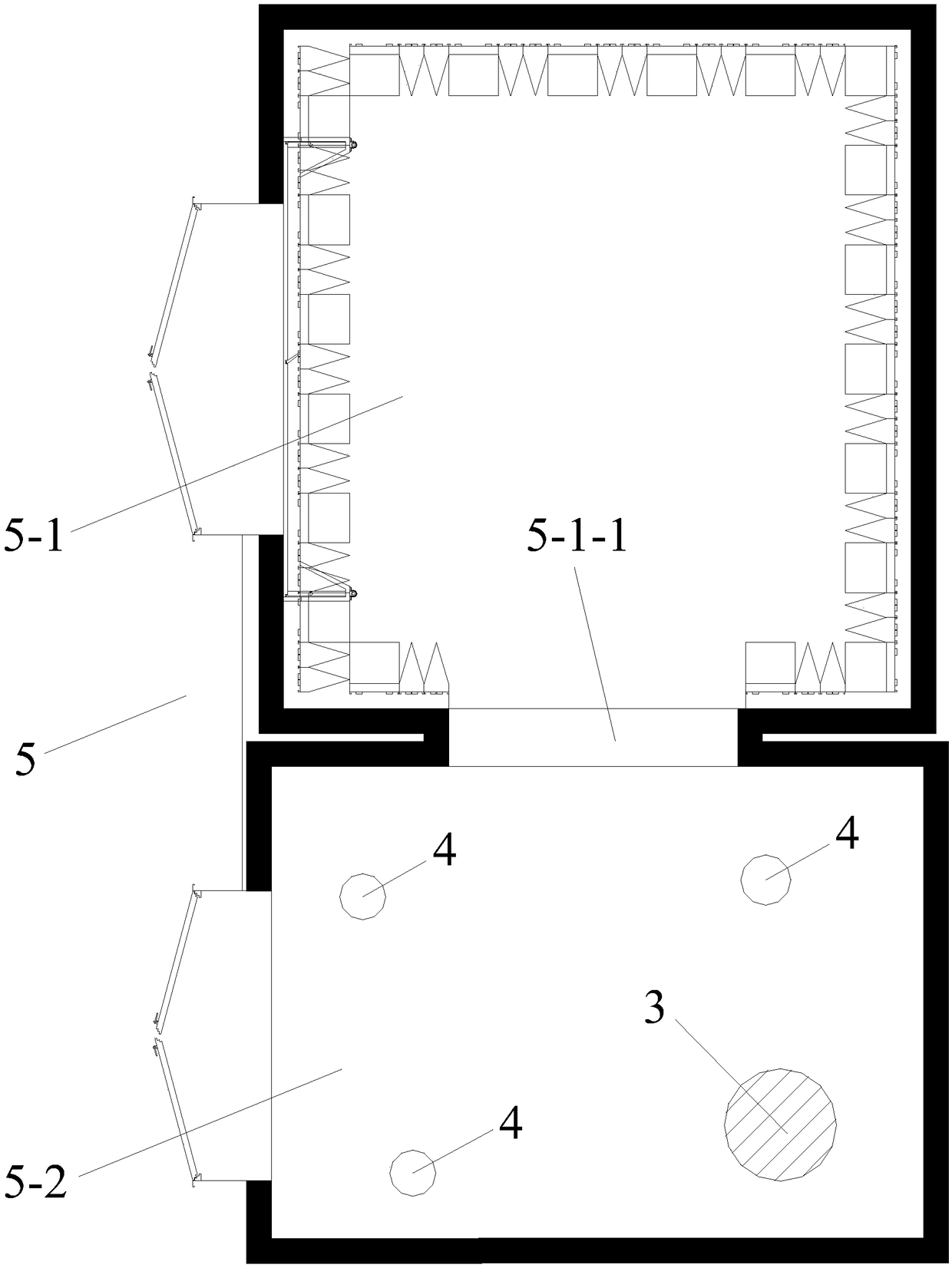

[0043] Step 1: According to the external dimensions of a single complete passageway 1 of the train, build a joint acoustic laboratory 5 that is sufficient to accommodate the passageway 1. The joint acoustic laboratory 5 includes an anechoic chamber 5-1 and a reverberation chamber 5-2; the anechoic chamber 5 -1 is rectangular, and its internal size is greater than the external dimension of a single complete channel 1 to be tested; the reverberation chamber 5-2 is square, and it and a side wall of the anechoic chamber 5-1 pass through the rectangular reverberation test window 5 - 1-1 communicate with each other; the overall dimension of the through ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sound absorption coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com