Test method for sound absorption coefficient in passenger compartment of rail train based on semi-anechoic chamber of whole vehicle

A technology of semi-anechoic chamber and sound absorption coefficient, which is applied in the test field of sound absorption coefficient inside rail train passenger compartment, can solve the problem of no reference for the solution formula, achieve the effects of avoiding external interference, improving accuracy, and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

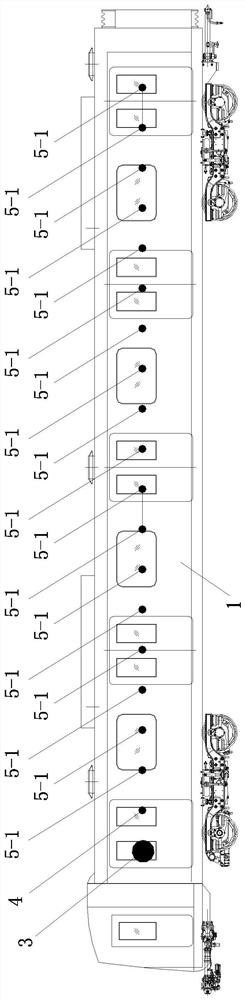

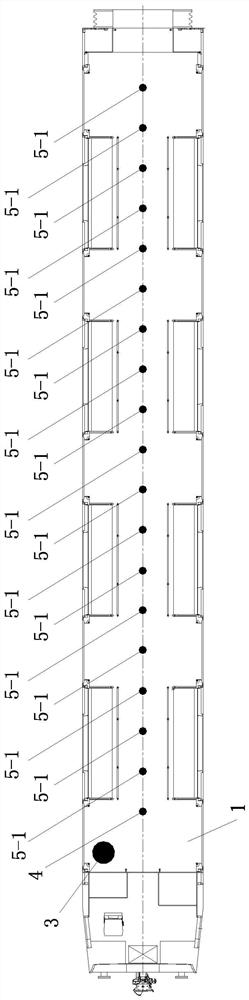

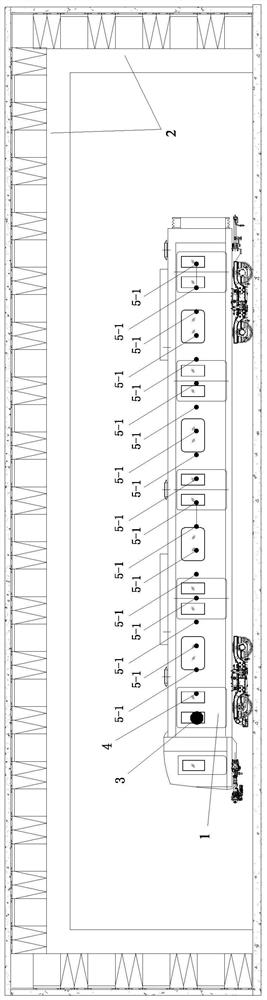

[0036] Such as Figure 1 to Figure 4 As shown, the method for testing the sound absorption coefficient in the passenger compartment of rail trains based on the semi-anechoic chamber of the whole vehicle of the present invention comprises the steps:

[0037] Step 1: According to the maximum external dimensions of various types of single-section train cars, build a vehicle semi-anechoic chamber 2 that is sufficient to accommodate a single-section train car in the ready state; The surface distance is greater than or equal to 5m; the cut-off frequency of the semi-anechoic chamber 2 of the vehicle is not greater than 50Hz; its natural frequency is not higher than 3.57Hz, and the vibration isolation efficiency for the excitation frequency of 50Hz is not less than 99%. The background noise is lower than 15dBA after the system is turned off;

[0038] Step 2: Place ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com