White oil sizing agent for composite graphene, preparation method thereof, as well as preparation method of composite fiber of graphene and UHMWPE (Ultrahigh Molecular Weight Polyethylene)

A composite graphene and composite fiber technology, applied in fiber processing, fiber chemical characteristics, melt spinning, etc., can solve the problems of serious agglomeration, wide distribution of graphene particle size, and difficulty in uniform and stable dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

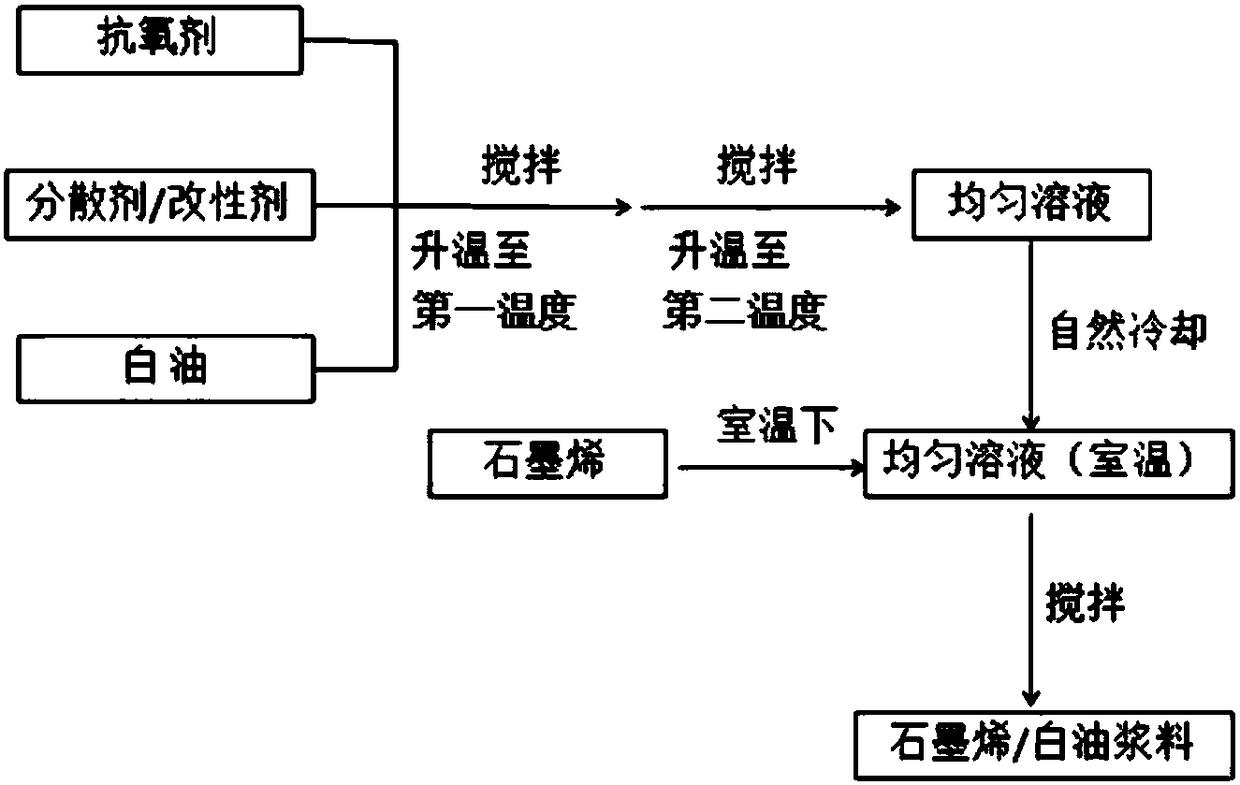

[0060]In another embodiment of the present invention, a kind of preparation method of the white oil slurry of graphene comprises:

[0061] 1) Pretreatment of white oil

[0062] Add component A and component B into white oil, and under stirring condition, heat until component A and component B are fully dissolved to form a uniform solution, and the solution is naturally cooled to room temperature, wherein the component A is anti Oxygen agent, the component B is a dispersant and / or modifier;

[0063] 2) Formation of graphene / white oil slurry

[0064] At room temperature, add the graphene powder into the solution obtained in step 1) under high-speed stirring, and continue stirring until a uniformly dispersed graphene / white oil slurry is formed.

[0065] According to an aspect of this embodiment, in the step 1, the heating method is as follows:

[0066] Under stirring conditions, firstly heat to the first temperature, keep it warm for 0.2-3 hours, then raise the temperature to ...

Embodiment 1

[0083] Preparation of white oil slurries, such as figure 1 :

[0084] Add antioxidant 1010 (0.01kg) and PSS (0.01kg) to white oil (99.96kg), heat to 110°C for 0.5h under stirring, then gradually raise the temperature to 130°C at a rate of 20°C / h ℃, and keep it warm for 4 hours until the antioxidant 1010 and PSS are fully dissolved to form a uniform solution, then cool naturally;

[0085] At room temperature, graphene powder (0.02kg) was gradually added to the above solution under high-speed stirring, and the stirring was continued for 1 hour to obtain a uniformly dispersed graphene / white oil slurry.

[0086] Preparation of composite fibers of graphene and UHMWPE:

[0087] Add 20kg (graphene accounts for 0.1wt% of UHMWPE) UHMWPE powder and 102.26kg white oil to the white oil slurry obtained by the above method to make a pre-spinning solution, enter the swelling tank and heat up to 100°C, and then pass through the dissolution tank , feeding kettle, and twin-screw extruder, th...

Embodiment 2

[0088] Example 2, such as figure 1 :

[0089] Preparation of white oil slurry:

[0090] Add antioxidant 1010 (0.02kg) and PSS (0.02kg) into white oil (99.94kg), heat to 115°C for 0.5h under stirring condition, then gradually raise the temperature to 135°C at a heating rate of 25°C / h ℃, and keep it warm for 5 hours until the antioxidant 1010 and PSS are fully dissolved to form a uniform solution, then cool naturally;

[0091] At room temperature, graphene powder (0.02kg) was gradually added to the above solution under high-speed stirring, and the stirring was continued for 2 hours to obtain a uniformly dispersed graphene / white oil slurry.

[0092] Preparation of composite fibers of graphene and UHMWPE:

[0093] Add 10kg (graphene accounts for 0.2wt% of UHMWPE of UHMWPE) UHMWPE powder and 1.17kg white oil in the graphene / white oil slurry that above-mentioned method obtains, make pre-spinning liquid, enter in the swelling kettle and be heated up to 100 ℃, again After dissolvi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com