Method for preparing high-heat-conductivity silicon nitride ceramic through normal pressure sintering

A technology of silicon nitride ceramics and normal pressure sintering, applied in the field of non-oxide ceramic preparation, can solve related properties (decreased mechanical properties and thermal properties, low thermal conductivity of normal pressure sintered silicon nitride ceramics, limited nitriding Development and application of silicon ceramics, etc., to achieve the effect of improving mechanical properties, easy control of conditions, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] 19.0g of silicon nitride powder and 1.0g of composite sintering aids (MgO and TiO 2 The molar ratio is 1:2) powder as raw material, absolute ethanol as solvent, placed in a ball mill tank for ball milling for 4 hours, then the dried and sieved mixture was placed in a mold, and dry-pressed at 30MPa to form the obtained biscuit Carry out cold isostatic pressing with a pressure of 200 MPa, place the final ceramic green body in a carbon tube furnace, use nitrogen as a protective atmosphere, and heat up to 1700°C, keep warm for 2 hours, then cool down with the furnace. A density of 3.14g cm can be obtained -3 , The relative density is 97%.

Embodiment 2

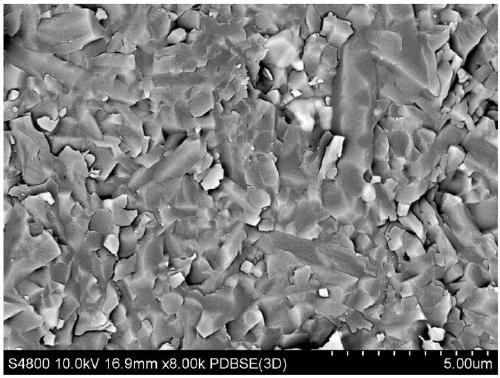

[0048] 18.6g of silicon nitride powder and 1.4g of composite sintering aids (MgO and TiO 2 The molar ratio is 1:1) powder as raw material, absolute ethanol as solvent, put it in a ball mill tank for ball milling for 4 hours, then put the dried and sieved mixture in a mold, dry press molding at 30MPa, and the obtained biscuit Carry out cold isostatic pressing with a pressure of 200 MPa, place the final ceramic green body in a carbon tube furnace, use nitrogen as a protective atmosphere, and heat up to 1780°C, keep warm for 1h, then cool down with the furnace. After another 6 hours of heat preservation at 1600 ° C, the material density, relative density, thermal conductivity, fracture toughness and Vickers hardness are 3.21 g cm -3 , 99.1%, 58.57W / (m·K), 5.28MPa·m 1 / 2 and 15.32GPa. figure 1 To obtain the SEM image of the sample. from figure 1 It can be seen that the material has distinct long columnar grains.

Embodiment 3

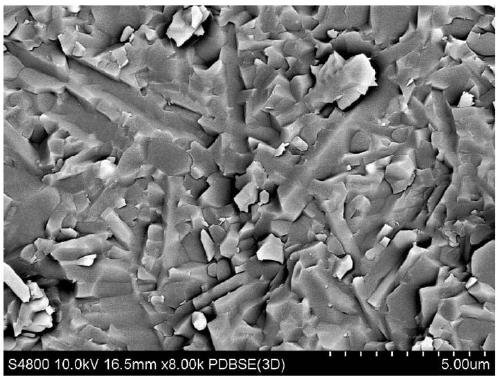

[0050] 18.0g of silicon nitride powder and 2.0g of composite sintering aids (MgO and TiO 2 The molar ratio is 2:1) powder as raw material, absolute ethanol as solvent, placed in a ball mill tank for ball milling for 4 hours, then the dried and sieved mixture was placed in a mold, and dry-pressed at 30MPa to form the obtained biscuit Carry out cold isostatic pressing with a pressure of 200 MPa, place the final ceramic green body in a carbon tube furnace, use nitrogen as a protective atmosphere, and heat up to 1780°C, keep warm for 2 hours, then cool down with the furnace. After 6 hours of heat preservation at 1600 ° C, the material density, relative density, thermal conductivity, fracture toughness, flexural strength and Vickers hardness are 3.20 g cm -3 , 98.8%, 59.84W / (m·K), 5.13MPa·m 1 / 2 , 668MPa and 15.06GPa. figure 2 To obtain the SEM image of the sample. from figure 2 It can be seen that the material has a larger grain size.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com