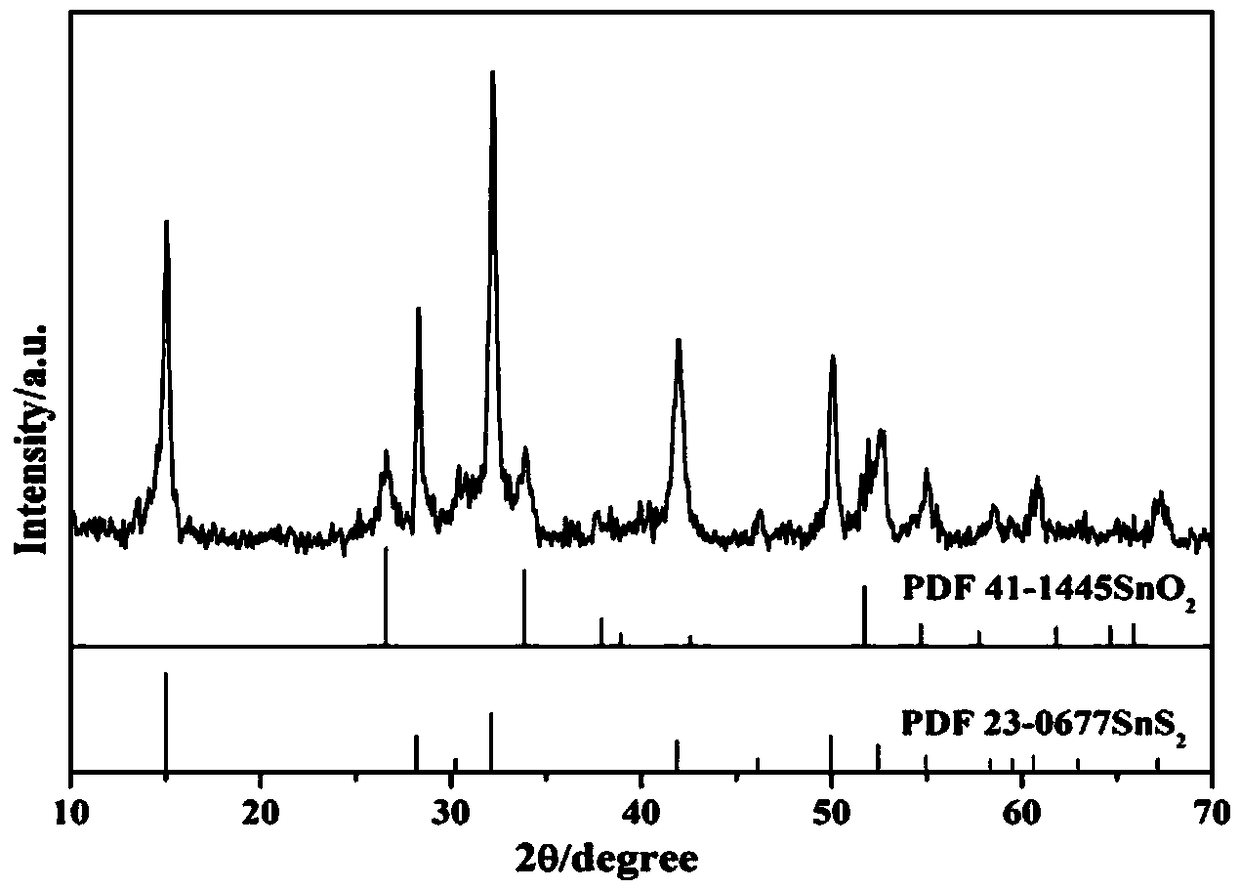

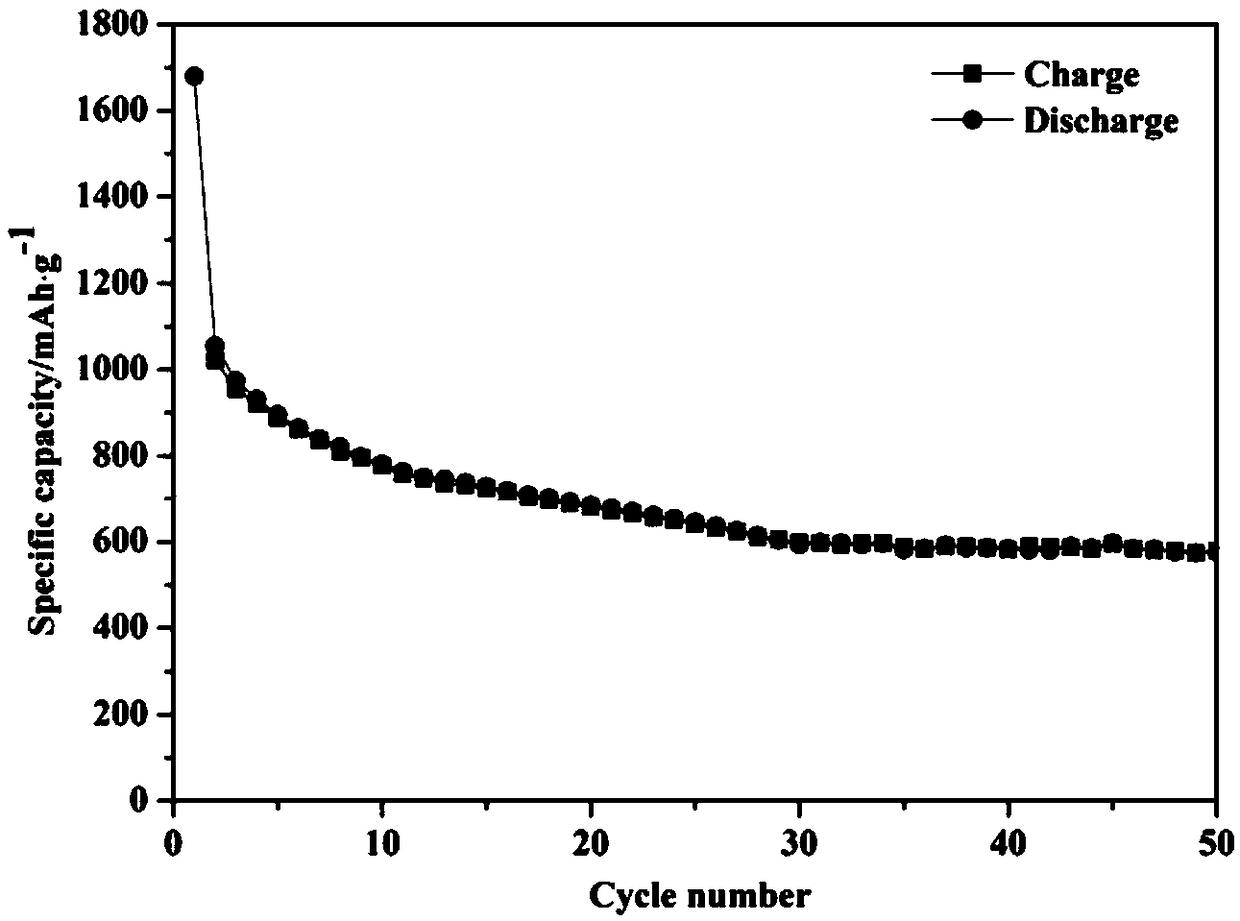

Preparation method of SnS2/SnO2 lithium ion battery anode material in hollow-sphere structure

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, structural parts, etc., can solve the high energy and cost requirements for production, cannot meet the demand for nanofiber dosage, and nanofiber materials are widely used Obstacles and other problems can be achieved to improve electrochemical performance, increase reactive active sites, and controllable grain growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1) 0.5g SnCl 4 ·5H 2 O was dissolved in 60 mL deionized water and absolute ethanol (V 去离子水 :V 无水乙醇 =1:5), make it fully dissolved to form solution A, according to the element mass ratio m Sn :m Na =(0.5:0.6) NaOH is dissolved in the above solution A to prepare solution B;

[0039] 2) Add 0.3g of urea to solution B under the action of magnetic stirring, continue to stir to form a uniform mixed solution C, and put solution C into a homogeneous hydrothermal reaction kettle to seal, the filling ratio is controlled at 40%, and put it into a homogeneous solution Hydrothermal reaction instrument, the reaction temperature is controlled at 160°C, and the reaction time is controlled at 12h;

[0040] 3) After the reaction is over, take out the precursor, wash with deionized water and absolute ethanol three times, respectively, and obtain a white precursor, then vacuum dry it at 80°C for 12 hours to obtain SnO 2 Precursor;

[0041] 4) Heating in a muffle furnace at 300°C for...

Embodiment 2

[0046] 1) 0.7102g SnCl 4 ·5H 2 O was dissolved in 60 mL deionized water and absolute ethanol (V 去离子水 :V 无水乙醇 =1:1), make it fully dissolved to form solution A, according to the element mass ratio m Sn :m Na =(0.7102:0.8002) NaOH is dissolved in the above-mentioned solution A and is mixed with solution B;

[0047] 2) Add 0.5g of urea into solution B under the action of magnetic stirring, continue to stir to form a uniform mixed solution C, put solution C into a homogeneous hydrothermal reaction kettle and seal it, the filling ratio is controlled at 50%, and put it into a homogeneous solution Hydrothermal reaction instrument, the reaction temperature is controlled at 180°C, and the reaction time is controlled at 24h;

[0048] 3) After the reaction is over, take out the precursor, wash with deionized water and absolute ethanol three times, respectively, and obtain a white precursor, then vacuum dry it at 80°C for 12 hours to obtain SnO 2 Precursor;

[0049] 4) Heating in a...

Embodiment 3

[0055] 1) 1g SnCl 4 ·5H 2 O was dissolved in 60 mL deionized water and absolute ethanol (V 去离子水 :V 无水乙醇 =5:1), make it fully dissolved to form solution A, according to the element mass ratio m Sn :m Na =(1:0.95) NaOH was dissolved in the above solution A to prepare solution B;

[0056] 2) Add 0.7g of urea to solution B under the action of magnetic stirring, and continue to stir to form a uniform mixed solution C.) Put solution C into a homogeneous hydrothermal reactor and seal it. The filling ratio is controlled at 60%, and put it into a homogeneous solution. Hydrothermal reaction instrument, the reaction temperature is controlled at 200°C, and the reaction time is controlled at 30h;

[0057] 3) After the reaction is over, take out the precursor, wash with deionized water and absolute ethanol three times, respectively, and obtain a white precursor, then vacuum dry it at 80°C for 12 hours to obtain SnO 2 Precursor.

[0058] 4) Heating in a muffle furnace at 500°C for 5 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com