Crane control system and control method

A control system and crane technology, applied in mechanical equipment, load suspension components, fluid pressure actuating devices, etc., can solve problems such as failure of hydraulic components, oil leakage from oil pipes, and threats to operation safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

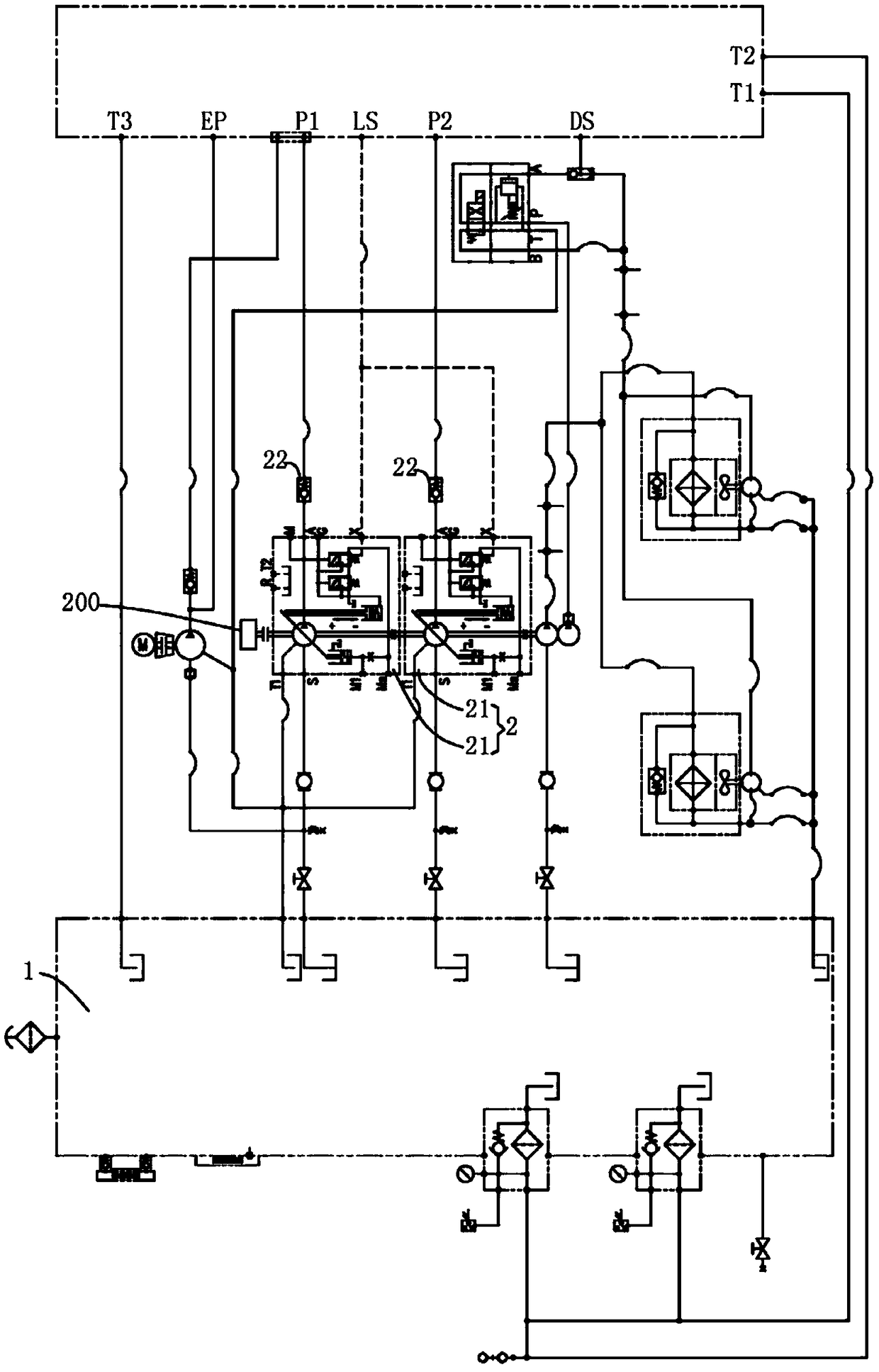

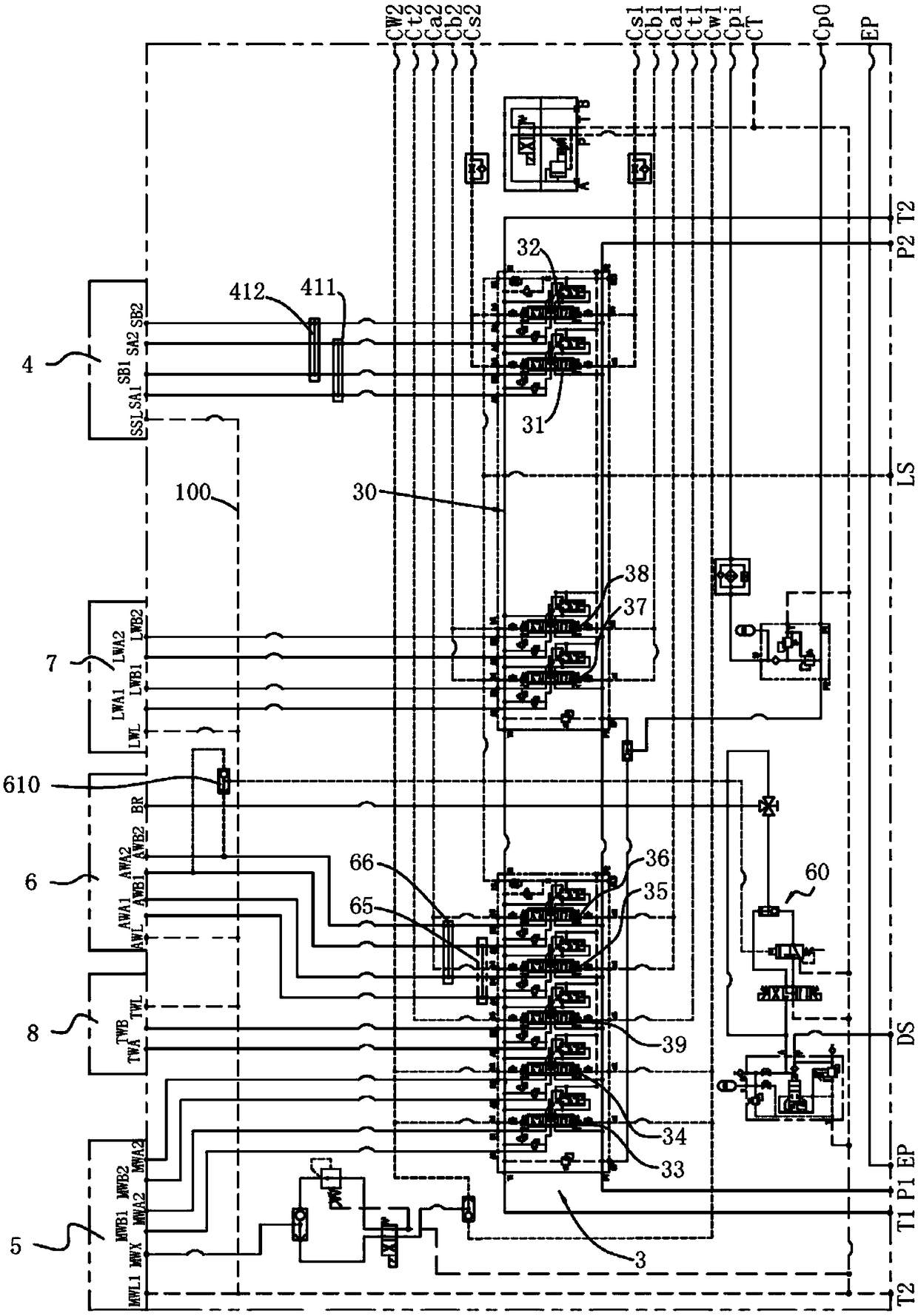

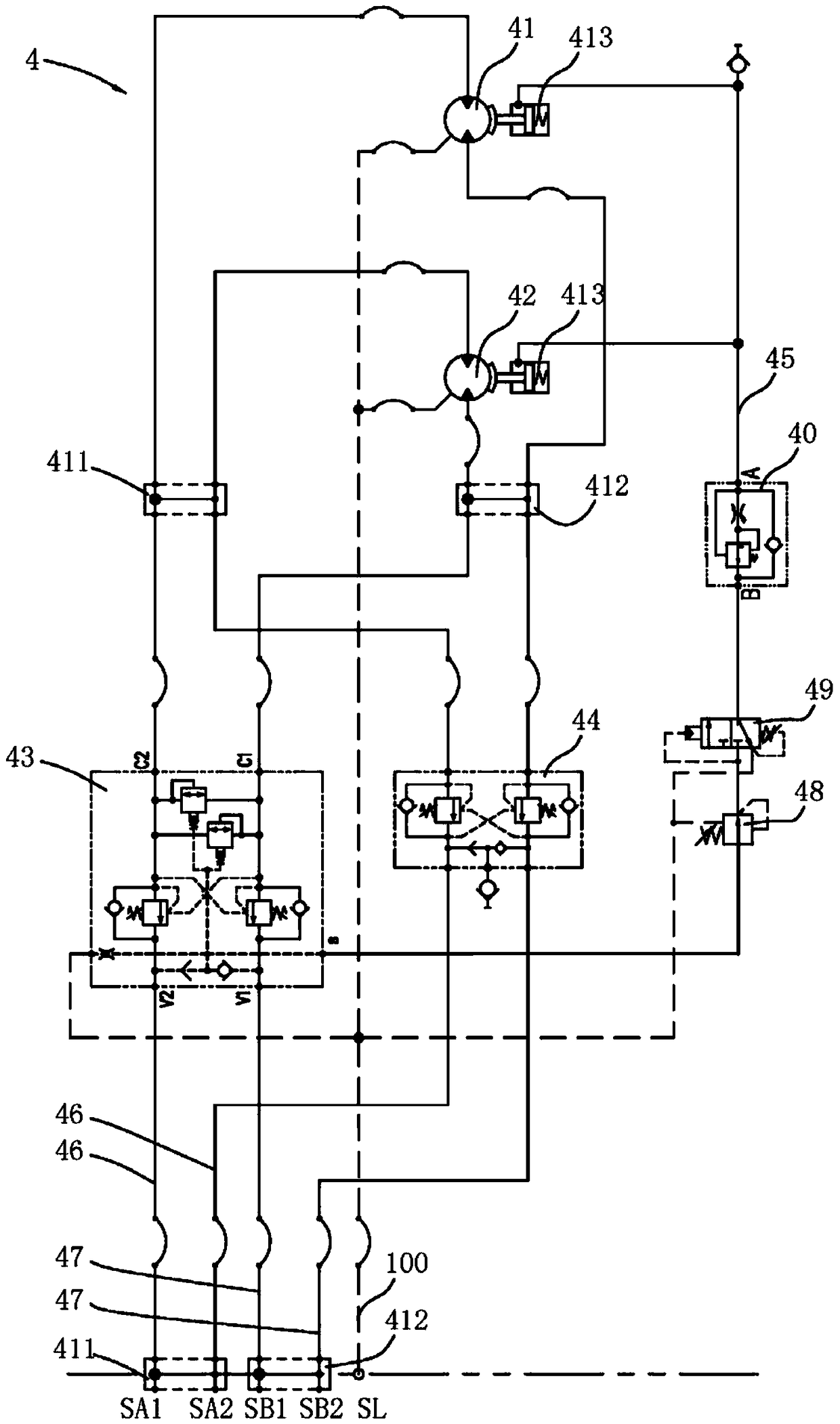

[0071] Such as Figure 1 to Figure 8 As shown, a crane control system includes a hydraulic oil tank 1, a main pump assembly 2, a switch assembly 3, a slewing system 4 for driving a slewing mechanism, a main hoisting system 5 for driving a main hoisting winch, and a The auxiliary hoisting system 6 of the auxiliary hoisting winch, the luffing system 7 used to drive the luffing winch, the steadier system 8 used to drive the steadier winch, the cooling system 9 used to cool the hydraulic oil and the A control system 10 that issues action signals.

[0072] Hydraulic oil tank 1 provides hydraulic oil for the entire crane control system, main pump assembly 2 provides main hydraulic oil for the entire control system, switch assembly 3, slewing system 4, main hoisting system 5, auxiliary hoisting system 6, luffing system 7 Cooperating with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com