Fully automatic micro-droplet emulsion generating device and generating method

A technology for generating devices and microdroplets, applied in the field of microfluidics, can solve the problems of sample loss, waste of channel use, and inability for users to know, and achieve the effect of isolating sample contamination and saving reagent usage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

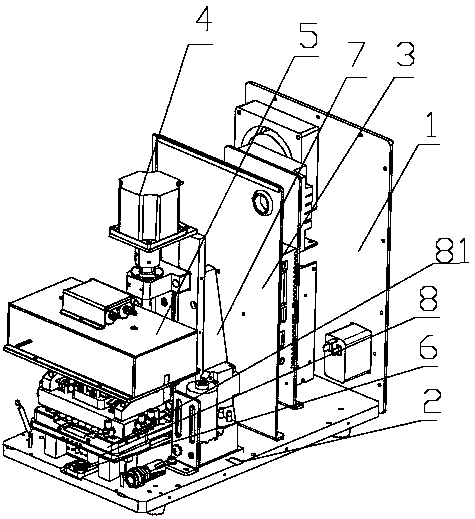

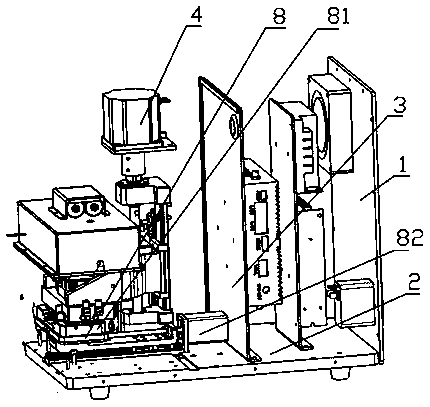

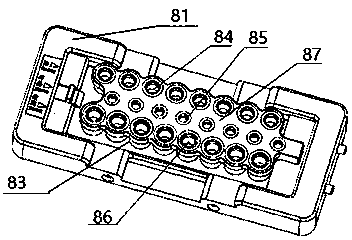

[0035] The technical solutions of the present invention are described in detail below in conjunction with the examples. The present invention discloses a fully automatic micro-droplet emulsion generating device and a generating method thereof. combine Figure 1-Figure 4 As shown, the device includes a base 2, a support plate 3 vertically arranged on the base, a slide rail 6 is arranged on the base 2, and a droplet generation chip is mounted on the slide rail 6. Specifically, a tray 8 is arranged on the slide rail 6 , the droplet generation chip 83 is arranged on the tray 8 through a chip holder 81 , and one side of the tray 8 is connected to a driving motor 82 . The movement of the drive motor 82 drives the droplet generation chip 83 to move horizontally on the slide rail 6 . The driving motor 82 is connected to the chip holder through a connecting rod, and one end of the driving motor 82 is disposed on the support plate 3 . Of course, the driving motor 82 can also be fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com