Gas-liquid and liquid-liquid reaction experimental instrument based on up-and-down stretchable jet mixing

A technology of liquid-liquid reaction and jet mixing, which is applied in chemical/physical/physical chemical fixed reactors, chemical instruments and methods, chemical/physical/physical chemical processes, etc., can solve the safety hazards of artificial feeding, reactants Inadequate mixing, difficult to control the feed rate and other problems, to achieve the effect of easy adjustment, complete reaction and providing reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

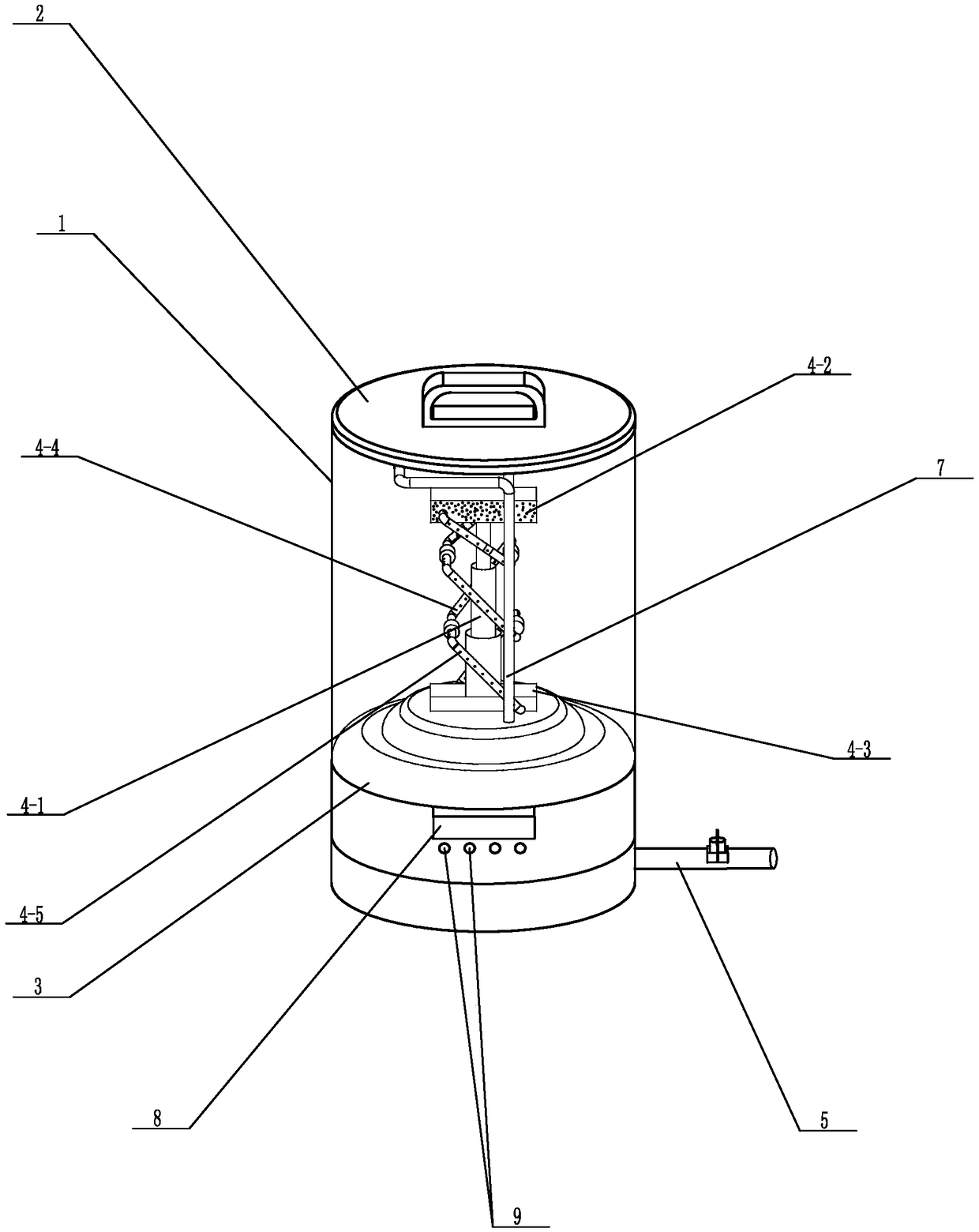

[0017] Such as figure 1 and figure 2 Propose a kind of specific embodiment of the present invention as shown, based on the gas-liquid, liquid-liquid reaction experiment instrument of up and down telescopic jet mixing, comprise the reaction tank 1 that is cylindrical, on the described reaction tank 1 detachable be provided with the tank that cooperates with it Cover 2, in order to facilitate the opening of the tank cover 2 and ensure the tight connection between the tank cover 2 and the reaction tank 1, in this embodiment, a screw thread is used between the tank cover 2 and the reaction tank 1 to realize a matable connection, and the tank cover 2 A frame-shaped handle 10 is provided on the top, which is convenient for opening and closing the tank cover 2. A tank base 3 is provided at the bottom of the reaction tank 1; The telescopic injection member 4 includes a lifting drive arranged in the tank base 3, the lifting drive is connected with an external power supply line, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com