Immersed type heating device

A technology of immersion heating and heating evaporation, applied in lighting and heating equipment, steam generation method using heat carrier, reducing greenhouse gas, etc., can solve the problems of high wine making cost, low heat energy utilization rate, low boiler efficiency, etc. , to achieve the effects of saving brewing costs, occupying a small space, and reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

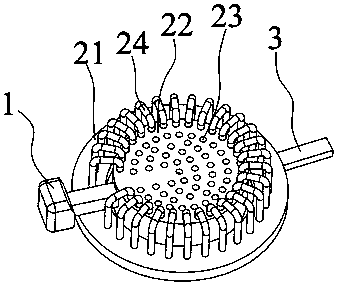

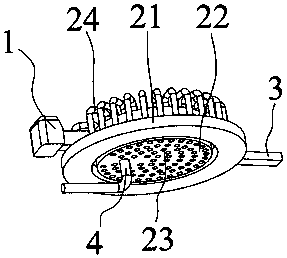

[0028] as attached figure 1 And attached figure 2 The immersion heating device shown in this embodiment includes a burner 1, a heat exchanger 2, a waste gas storage chamber 21, a combustion chamber 22, a heat exchange pipe 23, a connecting pipe 24, an exhaust pipe 3, and a detection pipe 4. Add about 0.8T of water into the pot body 3, place the steaming grid on the bottom pot body, then buckle the upper cover on the bottom pot body, place the fermented and mature grains that need to be distilled on the steaming grid, and the conventional distillation The retort bottom pot uses the burner 1 to directly heat the bottom of the bottom pot body 3. 0.8T water needs to be heated for 20 minutes with a 150,000 kcal / hour burner to make the water temperature reach 100°C boiling state. The whole process takes about 5 10,000 calorie energy, this device uses the heat exchanger 2 to be completely submerged in water, and the burner 1 is used to heat the heat exchanger 2, and the exhaust gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com