Steaming and brewing apparatus and steaming and brewing method for health liquor processing

A health care wine and wine steam technology, applied in the preparation of alcoholic beverages, etc., can solve the problems of incomplete discharge of wine steam, waste, etc., and achieve the effects of convenient opening and closing, improved use function, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

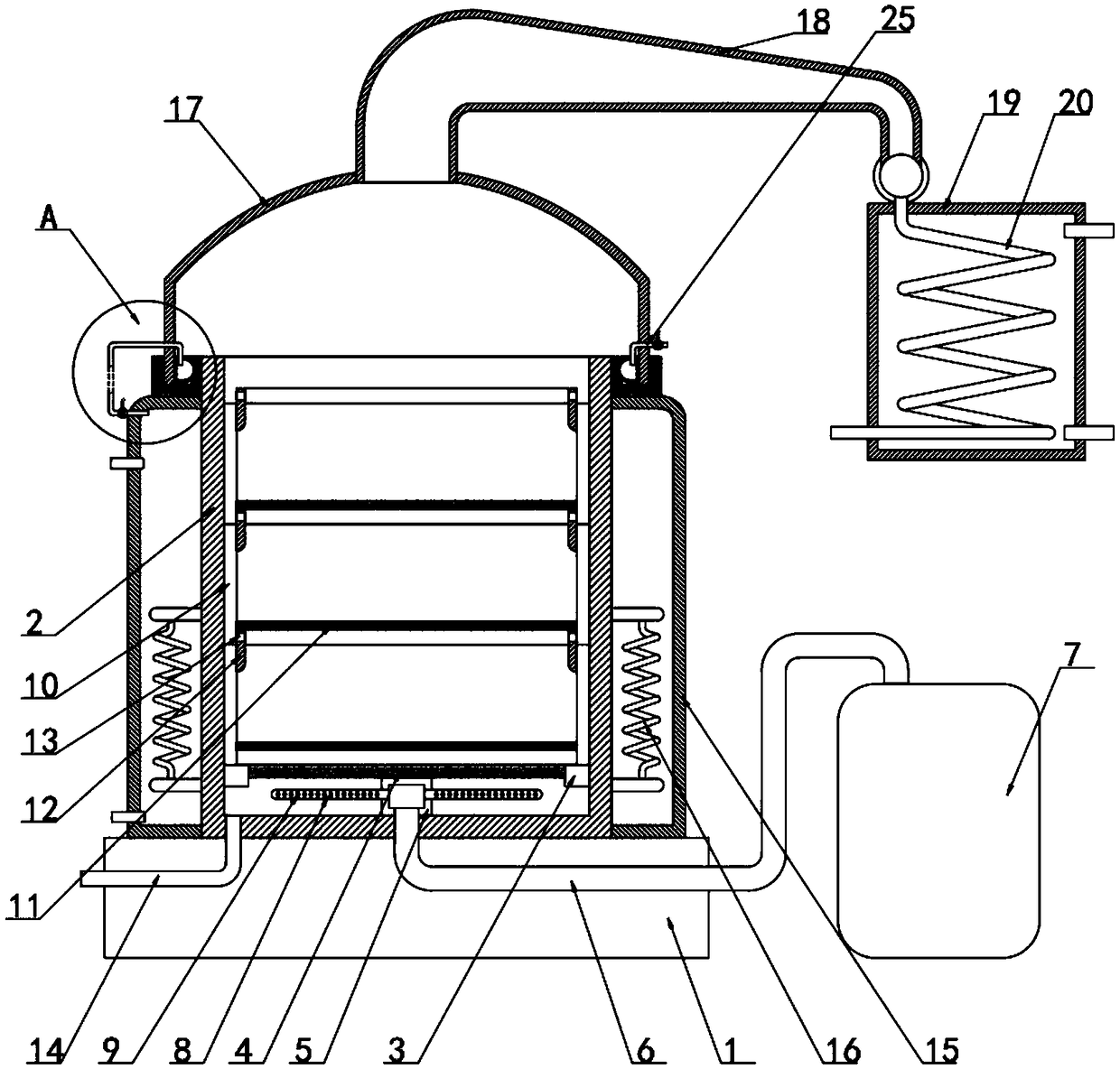

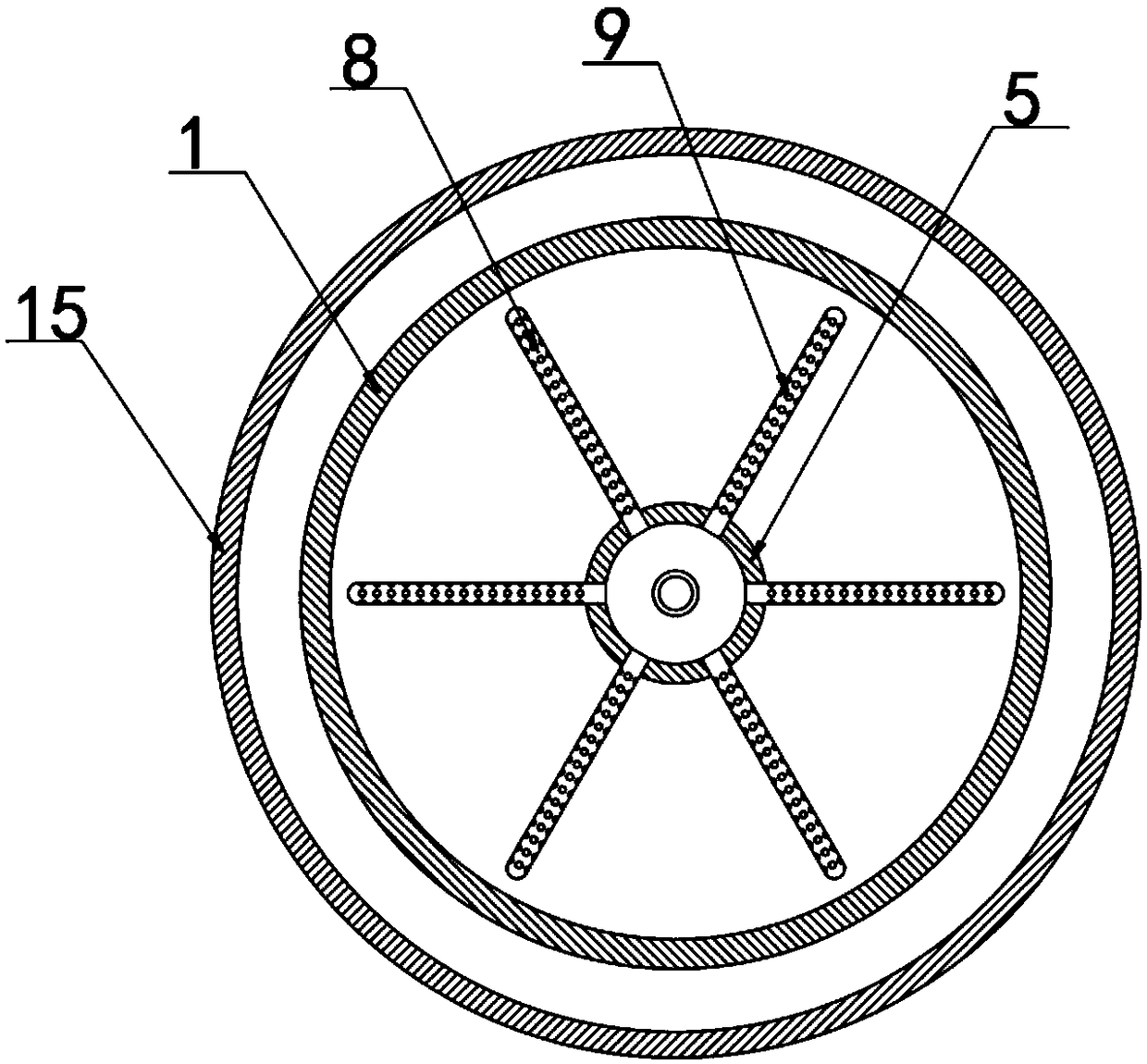

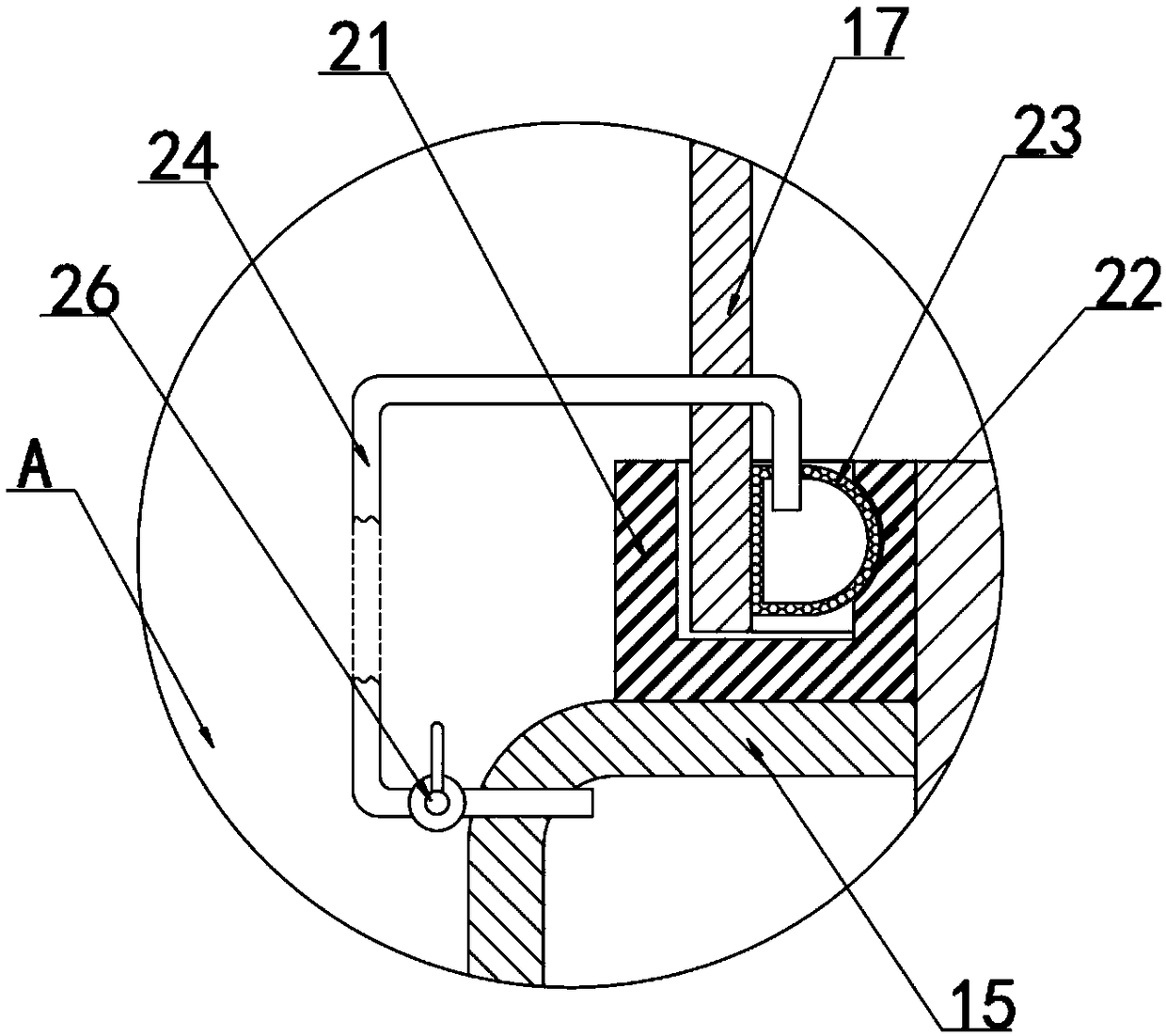

[0029] The present invention provides such as Figure 1-3 The steaming device for health wine processing shown includes a base 1, a retort main body 2 is arranged on the top of the base 1, and a support edge 3 is arranged inside the bottom of the retort main body 2, and the support edge 3 A metal mesh plate 4 is arranged inside, and the metal mesh plate 4 is made of stainless steel. A steam chamber 5 is arranged at the bottom of the retort main body 2, and a water vapor inlet pipe 6 is connected to the bottom of the steam chamber 5. The water vapor inlet pipe The other end of 6 is connected with a steam boiler 7, the surface of the steam chamber 5 is provided with a water vapor outlet pipe 8, the surface of the water vapor outlet pipe 8 is provided with a port 9, the top of the support rib 3 is provided with a steamer 10, and the support rib 3 is provided with a steamer 10. 3 Support the steamer 10 at the bottom, the bottom of the steamer 10 is provided with a sieve plate 11, ...

Embodiment 2

[0039] A steaming method for processing health wine, comprising the steaming device for processing health wine, and further comprising the following steps:

[0040] S1: distributing the raw materials into multiple steamers 10;

[0041] S2: Place the steamer 10 in the main body 1 of the steamer, and support the bottom steamer 10 by the support rib 3, and use the connecting ring 12 to connect the bottom of the top steamer 10 to realize the stacking of multiple steamers 10;

[0042] S3: The steam generated by the steam boiler 7 is transported to the steam chamber 3 at the bottom of the retort main body 2 through the steam inlet pipe 6, and then emerges from the port 9 on the surface of the steam outlet pipe 8;

[0043] S4: The water vapor is in full contact with the raw materials in the steamer 10, and the discharged wine vapor is transported to the condenser 19 through the wine steam outlet pipe 18;

[0044] S5: the condensation pipe 20 is condensed to produce wine;

[0045] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com