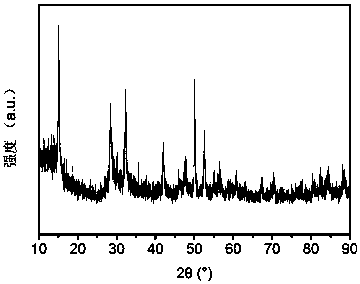

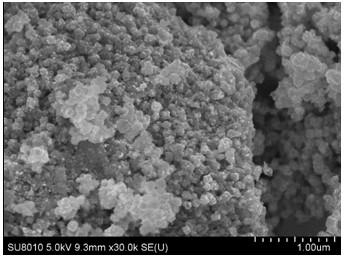

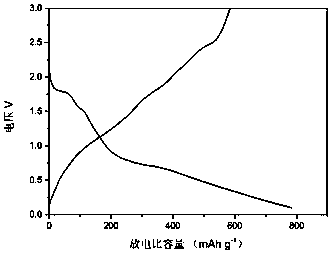

Preparation method of cubic nanometer zinc-tin sulfide for negative electrode material of sodium ion battery

A sodium-ion battery and negative electrode material technology, applied in the direction of zinc sulfide, battery electrodes, nanotechnology for materials and surface science, etc., can solve the problems of short cycle life, poor cycle stability of tin-based materials, etc., and achieve long cycle life , improve cycle stability, and avoid the effect of specific capacity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Dissolve 2.3g of tin tetrachloride in 100ml of absolute ethanol, stir magnetically at room temperature for 2 hours until a clear solution is formed; weigh 1.64g of zinc chloride and dissolve in 200ml of deionized water, stir magnetically at room temperature for 2 hour to form a clear solution; the absolute ethanol that is dissolved with tin tetrachloride is poured into deionized water filled with zinc chloride and stirred at room temperature for 3 hours;

[0029] (2) Weigh a certain mass of sodium hydroxide particle solution in deionized water, and magnetically stir at room temperature for 2 hours to form a clear sodium hydroxide solution with a molar concentration of 3 mol / L;

[0030] (3) Add 50ml of sodium hydroxide solution with a molar concentration of 3mol / L to the mixed solution of tin source and zinc source obtained in step (1), stir magnetically at room temperature for 5 hours to form a uniform white suspension, and then use deionized Centrifugal washing wit...

Embodiment 2

[0035](1) Weigh 2.3g of tin tetrachloride and dissolve it in 100ml of absolute ethanol, stir magnetically at room temperature for 2 hours until a clear solution is formed; weigh 1.87g of zinc acetate and dissolve it in 300ml of deionized water, and stir magnetically for 2 hours at room temperature To form a clear solution; the absolute ethanol dissolved with tin tetrachloride was poured into deionized water containing zinc acetate and stirred at room temperature for 3 hours;

[0036] (2) Weigh a certain mass of sodium hydroxide particle solution in deionized water, and magnetically stir for 2 hours at room temperature to form a clear sodium hydroxide solution with a molar concentration of 5 mol / L;

[0037] (3) Add 60ml of sodium hydroxide solution with a molar concentration of 5mol / L to the mixed solution of tin source and zinc source obtained in step (1), stir magnetically at room temperature for 5 hours to form a uniform white suspension, and then use deionized Centrifugal w...

Embodiment 3

[0042] (1) Weigh 1.5g of stannous chloride and dissolve it in 100ml of absolute ethanol, stir magnetically for 2 hours at room temperature until a clear solution is formed; weigh 1.07g of zinc sulfate and dissolve it in 200ml of deionized water, stir magnetically for 2 hours at room temperature To form a clear solution; the absolute ethanol dissolved with tin protochloride was poured into deionized water containing zinc sulfate and stirred at room temperature for 3 hours;

[0043] (2) Weigh a certain mass of sodium hydroxide particle solution in deionized water, and magnetically stir at room temperature for 2 hours to form a clear sodium hydroxide solution with a molar concentration of 1 mol / L;

[0044] (3) Add 50ml of sodium hydroxide solution with a molar concentration of 1mol / L to the mixed solution of tin source and zinc source obtained in step (1), stir magnetically at room temperature for 5 hours to form a uniform white suspension, and then use anhydrous Ethanol centrifu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com