Polysaccharide modified MBG scaffold, tissue repair scaffold, and preparation method and application thereof

A tissue repair and polysaccharide technology, used in tissue regeneration, medical science, prosthesis, etc., can solve the problems of poor application of bone repair materials, excessive toxic and side effects, insufficient stability, etc., and achieve stable and long-acting slow-release growth factors. , good biocompatibility, high loading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

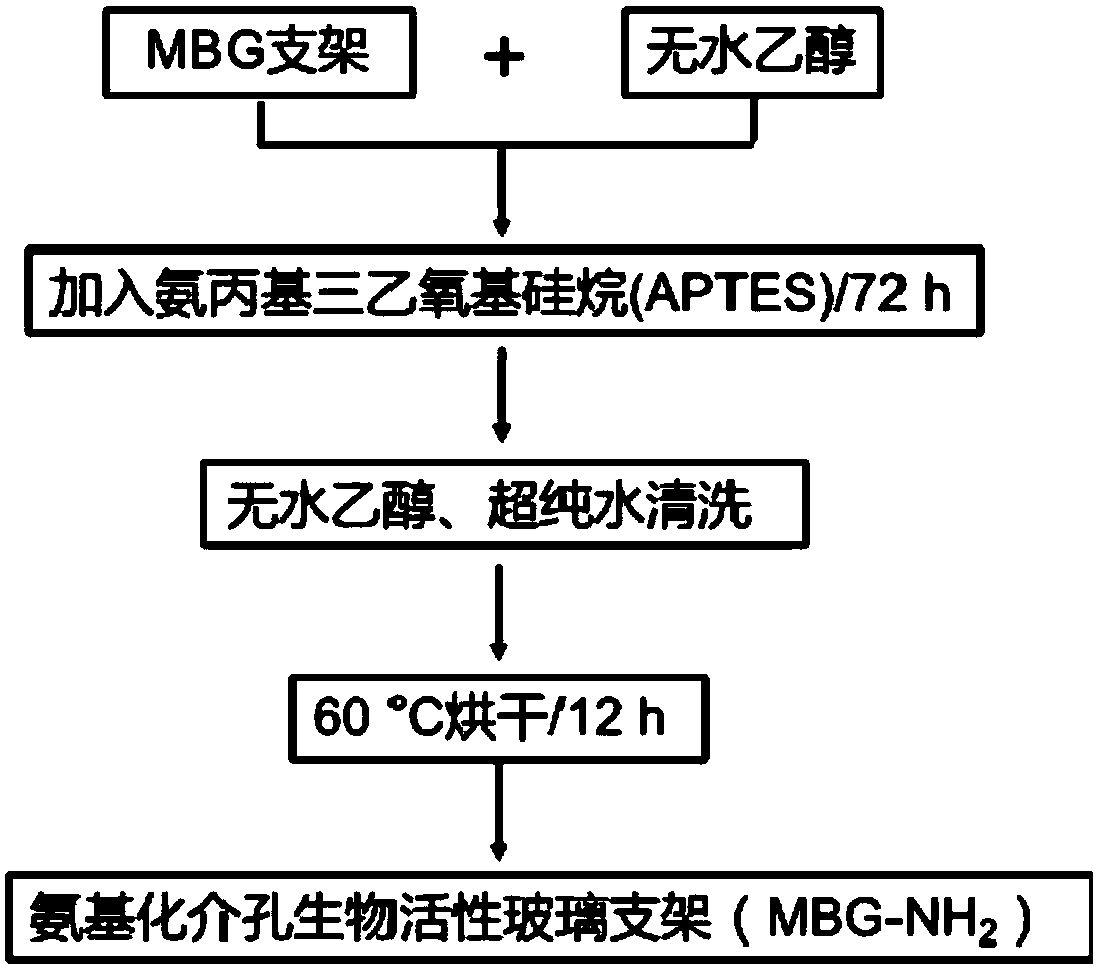

[0101] The above-mentioned preparation method of the MBG stent has a simple technological process and can be operated on a large scale industrially. By adjusting the polyurethane sponge template, MBG stents with different shapes and structures can be obtained to meet different actual needs. The MBG scaffold obtained by the method has a uniform structure and a stable microscopic shape, which is beneficial to the operation of the amino group and / or polysaccharide modification process in the later stage.

[0102] In a preferred embodiment of the present invention, according to the actual needs and requirements of tissue repair, the required template can be prepared by 3D printing, so as to prepare the required MBG scaffold, or the MBG scaffold can be prepared directly by 3D printing .

[0103] In a preferred embodiment of the present invention, the preparation of MBG sol comprises the following steps:

[0104] (a) Add 300mL of absolute ethanol and 6g of 0.5M HCl to the reaction ...

Embodiment 1

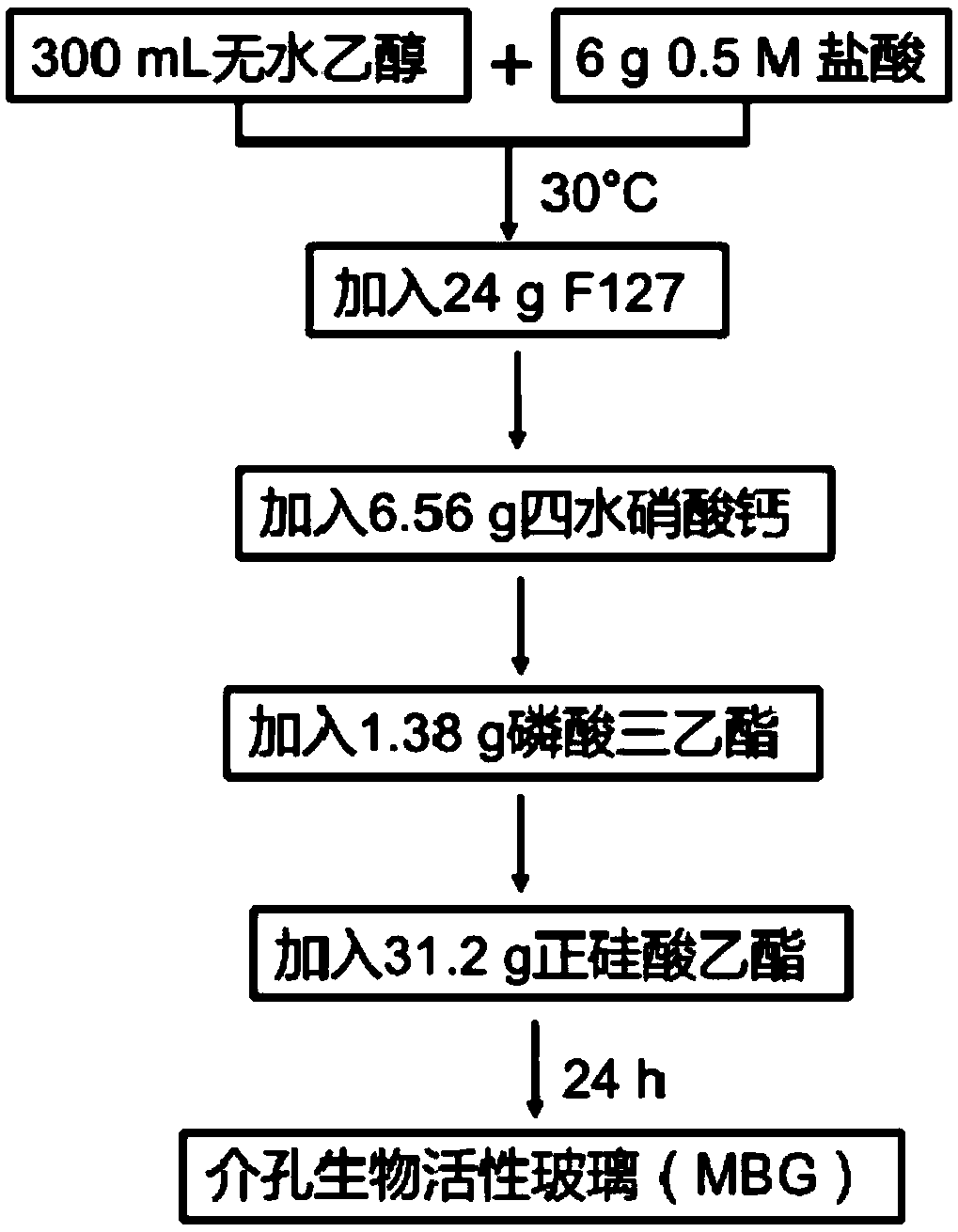

[0130] The preparation of embodiment 1 mesoporous active glass (MBG)

[0131] The flow chart of the preparation steps of mesoporous active glass (MBG) is as follows: figure 1 shown. Specific steps are as follows:

[0132] (a) Add 300mL of absolute ethanol and 6g of 0.5M HCl to the reaction vessel in a 30°C water bath;

[0133] (b) Add 24g F127 (EO 106 PO 70 EO 106 ) vigorously stirred until completely dissolved, and the solution was in a clear state;

[0134] (c) Add 6.56g calcium nitrate tetrahydrate (Ca(NO 3 ) 2 4H 2 0), stirred for 10min until it was completely dissolved;

[0135] (d) adding 1.38 g of triethyl phosphate (TEP);

[0136] (e) Add 31.2 g tetraethyl orthosilicate (TEOS) dropwise;

[0137] (f) After the addition of the reagents, keep stirring vigorously in a water bath at 30°C for 24 hours.

Embodiment 2

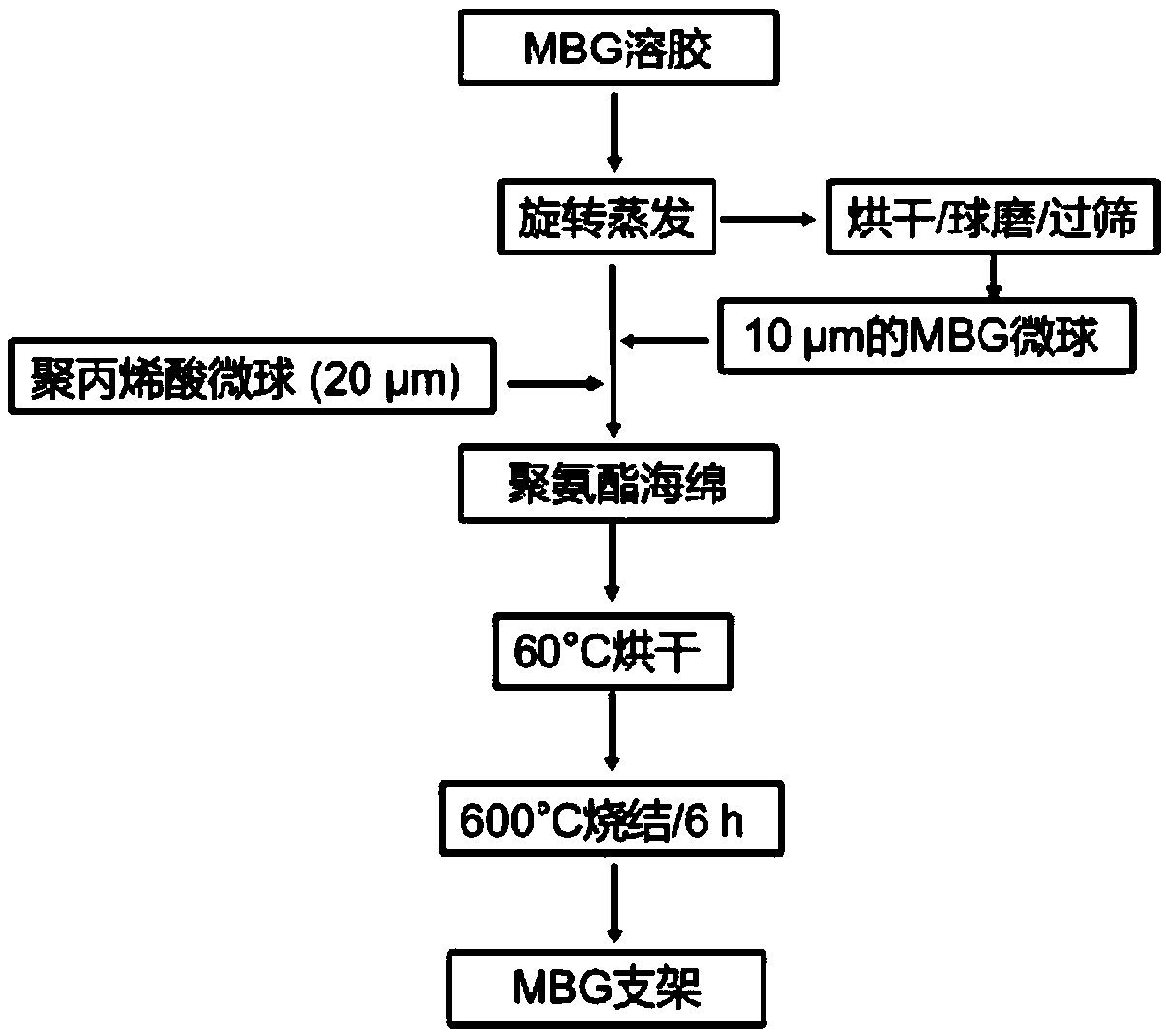

[0138] Example 2 Preparation of MBG scaffold

[0139] The flow chart of the preparation steps of MBG scaffold is as follows: figure 2 shown. Specific steps are as follows:

[0140] (a) Using a polyurethane sponge as a macroporous template. After the polyurethane sponge is processed into the corresponding specifications, it is soaked in 20% NaOH solution and rubbed for 2 hours for pretreatment;

[0141] (b) Rotate the prepared MBG sol on a rotary evaporator at 60°C for 30 min to obtain a viscosity of 4×10 4 -6×10 4 mPa·s viscous sol;

[0142] (c) partially drying the sol prepared in (b), ball milling and sieving to obtain MBG microspheres with a particle size of about 10 μm;

[0143] (d) The MBG microspheres prepared in (c) and the micropore pore-forming agent (polyacrylic acid microspheres, 20 μm) were uniformly mixed at a mass ratio of 1:1:6 (MBG microspheres: polyacrylic acid microspheres: MBG sol) Mixed into (b) the MBG sol after rotary evaporation treatment, and wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com