Solution method for in-situ preparation of molybdenum disulfide/graphite paper electrode

An in-situ preparation technology of molybdenum disulfide, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as weak adhesion between molybdenum disulfide and the substrate, uneven dispersion of molybdenum disulfide, complex process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Dissolve molybdenum chloride and thiourea in ethanol under stirring, wherein the concentrations of molybdenum chloride and thiourea are 0.33mol / L and 0.66mol / L respectively, and then drop-coat the mixed solution onto the surface of graphite paper treated with hydrophilization (The surface of graphite paper contains a large amount of -OH, -COOH, -NH 2 ), dried and annealed in Ar at 800°C for 60 min. After the sample is cooled naturally, the molybdenum disulfide / graphite paper electrode can be obtained.

Embodiment 2

[0024] Dissolve molybdenum chloride and thiourea in ethanol under stirring, wherein the concentrations of molybdenum chloride and thiourea are 0.33mol / L and 0.99mol / L respectively, and then drop-coat the mixed solution onto the hydrophilized graphite paper Surface (the surface of graphite paper contains a large amount of -OH, -COOH, -NH 2 ), dried and annealed in Ar at 800°C for 60 min. After the sample is cooled naturally, the molybdenum disulfide / graphite paper electrode can be obtained.

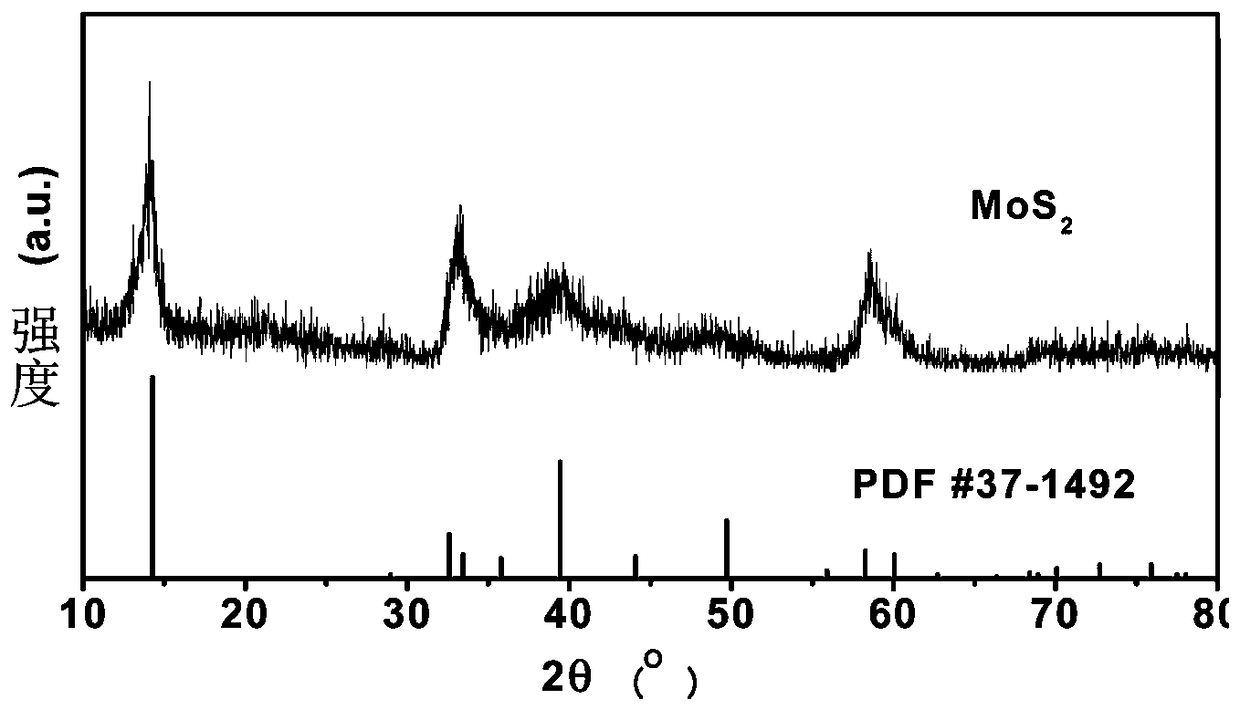

[0025] figure 1 The powder XRD of the sample prepared in this embodiment is shown. By working with standard PDF cards (MoS 2 PDF#37-1492) comparison shows that the prepared sample is molybdenum disulfide. It shows that after annealing in Ar at 800°C, molybdenum chloride and thiourea react to form molybdenum disulfide.

[0026] figure 2 SEM image of the sample prepared for this implementation example. The brick shape in the figure is MoS 2 , the bottom is graphite paper, it can be ...

Embodiment 3

[0032] Dissolve molybdenum chloride and thiourea in ethanol under stirring, wherein the concentrations of molybdenum chloride and thiourea are both 0.33mol / L and 1.32mol / L respectively, and then drop-coat the mixed solution onto the hydrophilized graphite paper Surface, dried and annealed in Ar at 800°C for 60min. After the sample is cooled naturally, the molybdenum disulfide / graphite paper electrode can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com