A method for improving magnetic properties of anisotropic magnetoresistance permalloy film

An anisotropic magnetic and permalloy technology is applied in the field of improving the magnetic properties of anisotropic magnetoresistance permalloy thin films, and can solve the problems of the influence of permalloy thin film magnetic properties, the increase of the thickness of the magnetic dead layer, and the dead layer. Achieve the effects of improving AMR characteristics, reducing coercive force, and improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with specific embodiment and accompanying drawing, the present invention is described in detail:

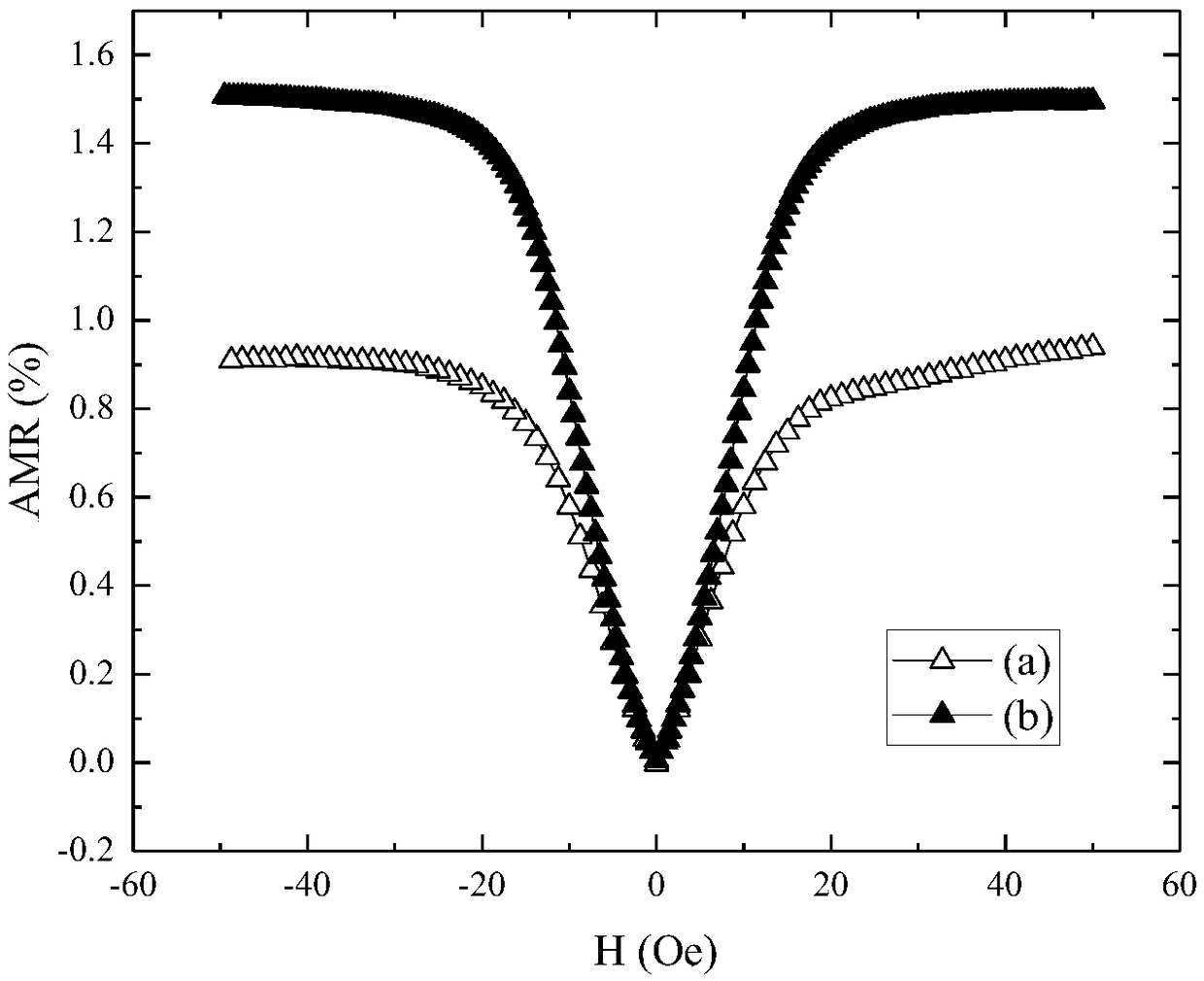

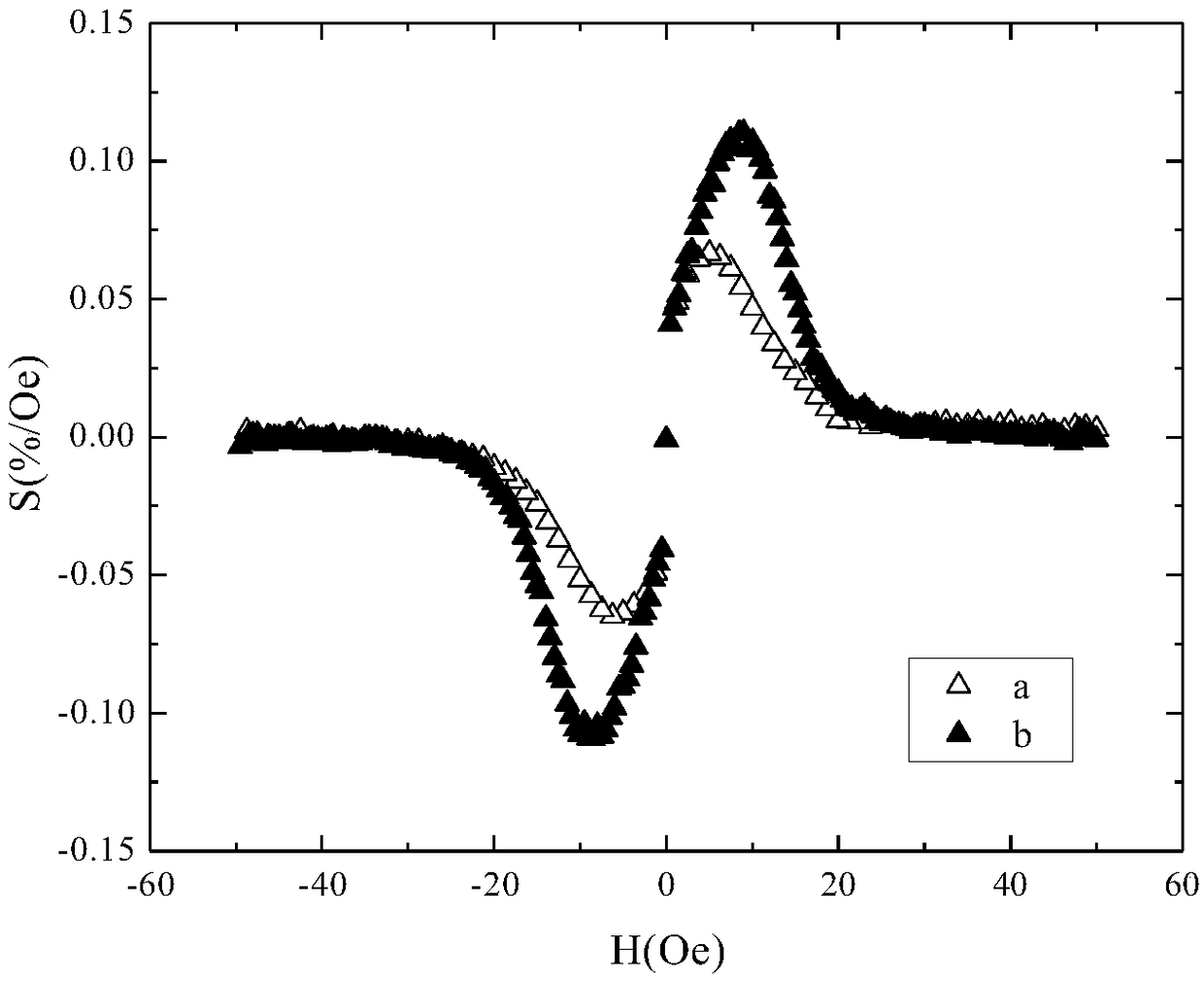

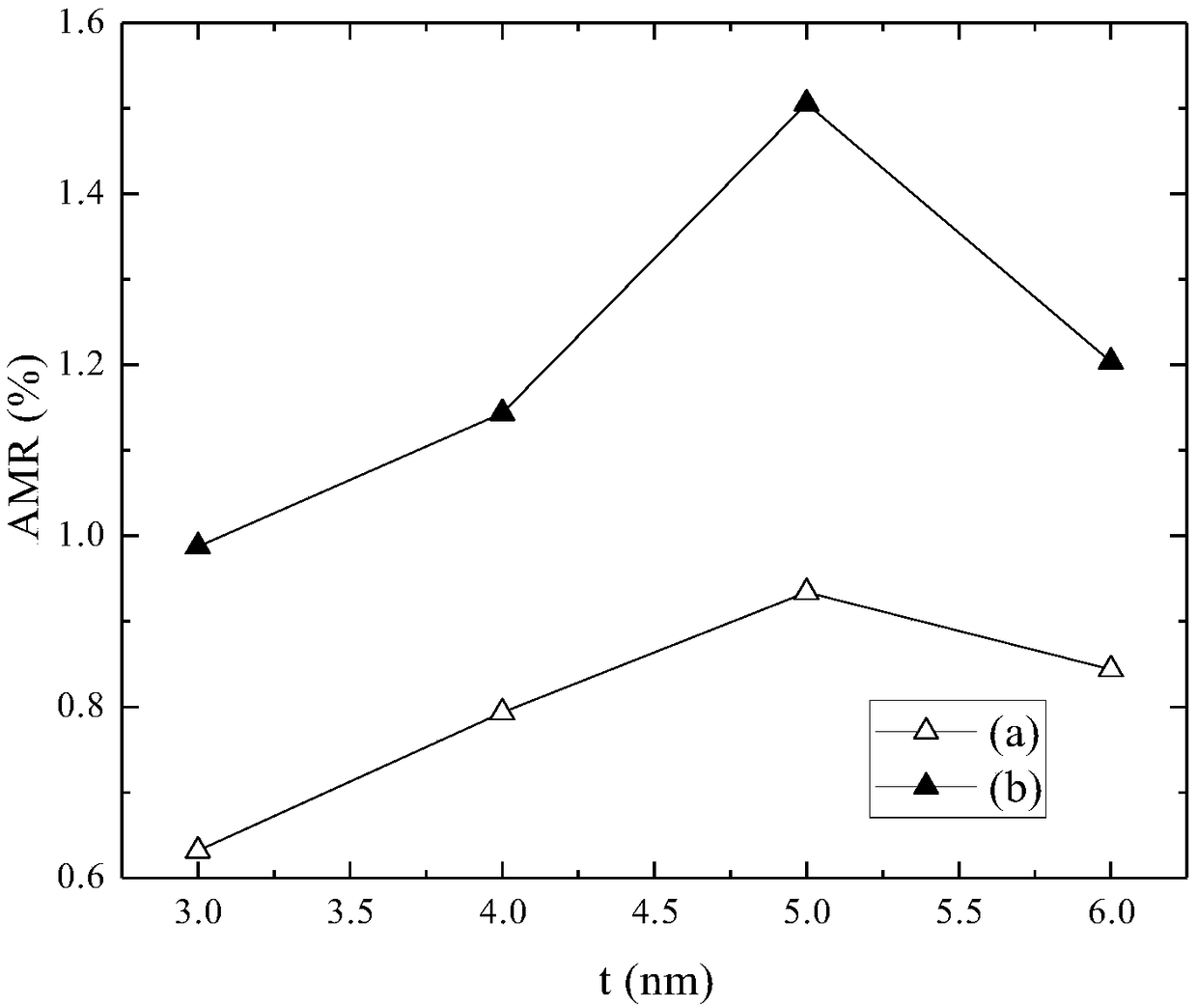

[0021] A method for improving the magnetic properties of an anisotropic magnetoresistance permalloy thin film is characterized in that a multilayer film structure in which a buffer layer, a NiFe magnetic thin film and a protective layer are stacked is sequentially formed on a substrate by a magnetron sputtering method, said The material of the buffer layer is TaNb alloy; before sputtering, the background vacuum of the magnetron sputtering equipment is 8×10 -5 Pa, the sputtering atmosphere is 99.999% high-purity argon gas, and the sputtering pressure is 0.2Pa; in this embodiment, the silicon substrate is used as the substrate, and the TaNb alloy is used as the buffer layer at the bottom, and then the permalloy layer is sputtered successively. Namely NiFe magnetic thin film, sputter protective layer on the permalloy layer at last to protect the NiFe magn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com