Anti-atomization device for fuel nozzle test bench

A technology of fuel nozzles and test benches, which is applied in the direction of measuring devices, engine tests, and mechanical parts tests, etc. It can solve the problems of limited function, interference test results, and improvement of test result accuracy, so as to prevent rebound, increase contact area, The effect of reducing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation of the present invention will now be described with reference to the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

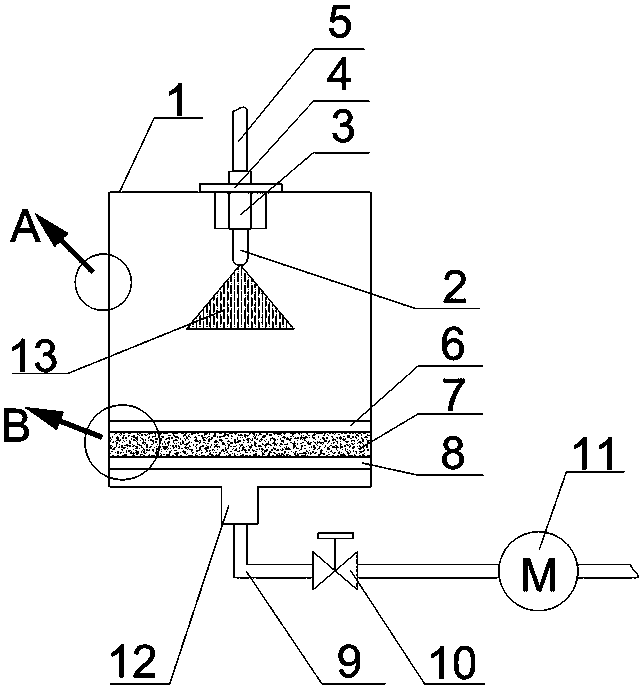

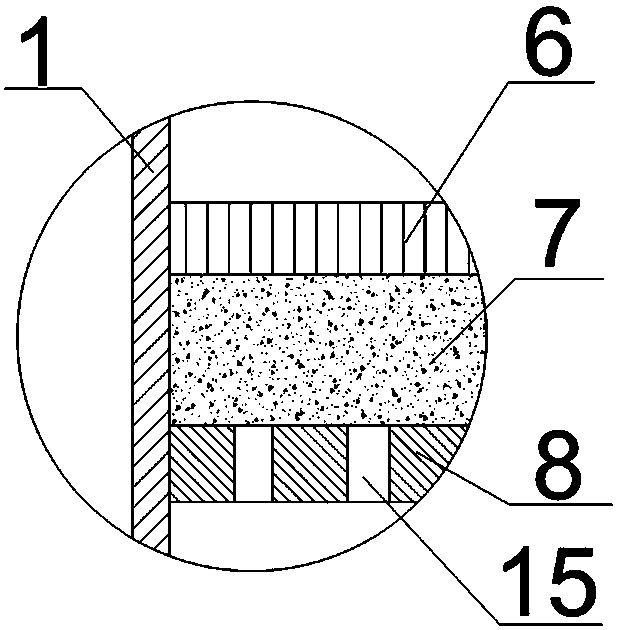

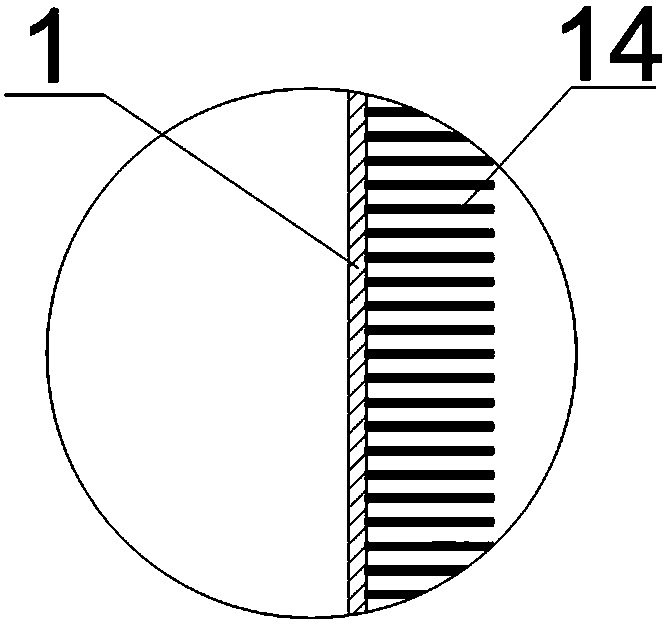

[0032] Such as figure 1 with figure 2 As shown, the present invention provides an anti-fog device for a fuel nozzle test bench, which includes a test bench case 1, the fuel nozzle 2 is installed above the interior of the test bench case 1, and the interior of the test bench case 1 also includes a filamentous adsorption layer 7 , flow stabilizing plate 8 and air suction port 12, wherein: the filamentous adsorption layer 7 is arranged below the fuel nozzle 2, and the steady flow plate 8 is arranged below the filamentary adsorption layer 7 for evenly passing the air flow; the suction port 12 is arranged at Below the stabilizing plate 8, it is us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com