Impact load self-adaptive buffer device

A buffer device, shock load technology, applied in the direction of spring, shock absorber, spring/shock absorber, etc., can solve the problems of large vibration, inability to adjust the flow hole, small resistance, etc., to improve reliability and improve self-adaptation performance, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

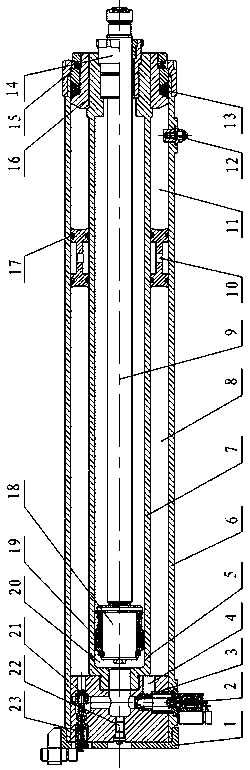

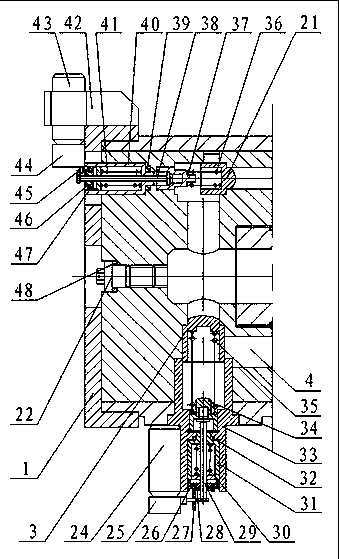

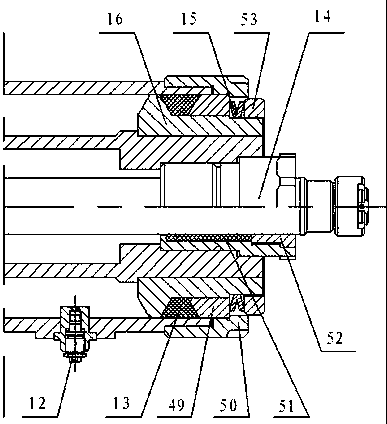

[0021] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

[0022] Such as figure 1 As shown, a shock load adaptive buffer device includes an air storage tank 7 and a buffer tank 6. The air storage tank 7 is sealed and arranged in the buffer tank. A piston 18 is arranged in the air storage tank 7, and one side of the piston 18 forms an I Cavity 20, the other side of the piston 18 is provided with a piston rod 9, and one end of the piston rod 9 extends out of the air storage cylinder; a floating piston 10 is arranged between the air storage cylinder 7 and the buffer cylinder 6, and the floating piston 10 connects the air storage cylinder 7 and the buffer cylinder 6 The chamber between the two chambers is divided into II chamber 8 and III chamber 11. A buffer valve 3 and a reset valve 21 are arranged between the air storage cylinder 7 and the buffer cylinder 6. The buffer valve 3 is adjusted by the buffer valve adjustment de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com