Columnar layer double-mode structure thermal barrier coating and preparation method thereof

A technology of thermal barrier coating and structural heat, applied in coating, metal material coating process, fusion spraying, etc., can solve the problem of sacrificing heat insulation ability, achieve excellent heat insulation performance, improve service life, high strain The effect of tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A preparation process of a thermal barrier coating with a high heat insulation and long life column / layer dual-mode structure, comprising the following steps:

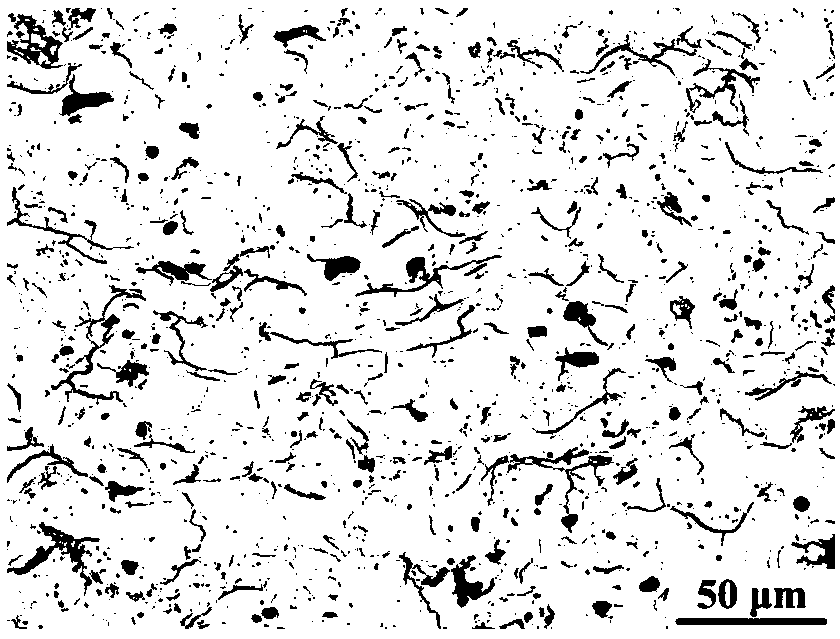

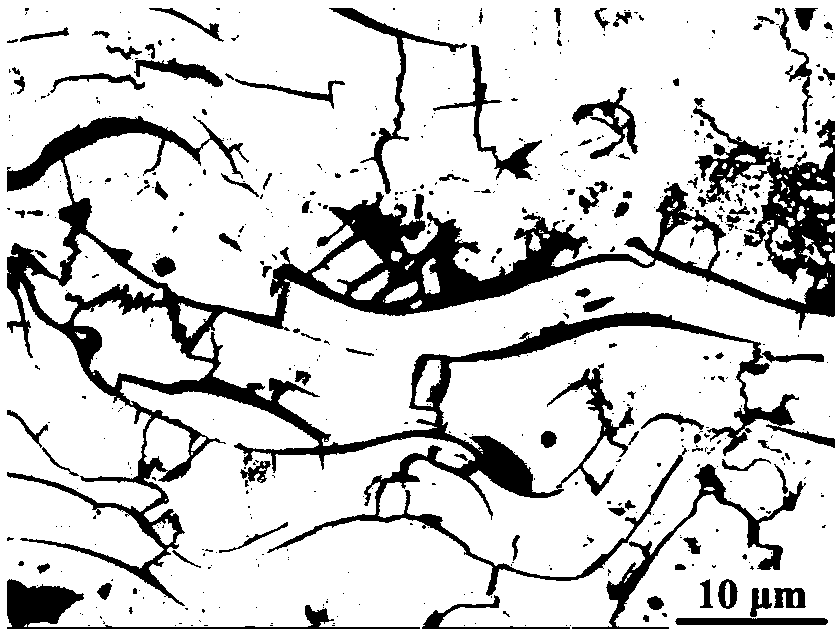

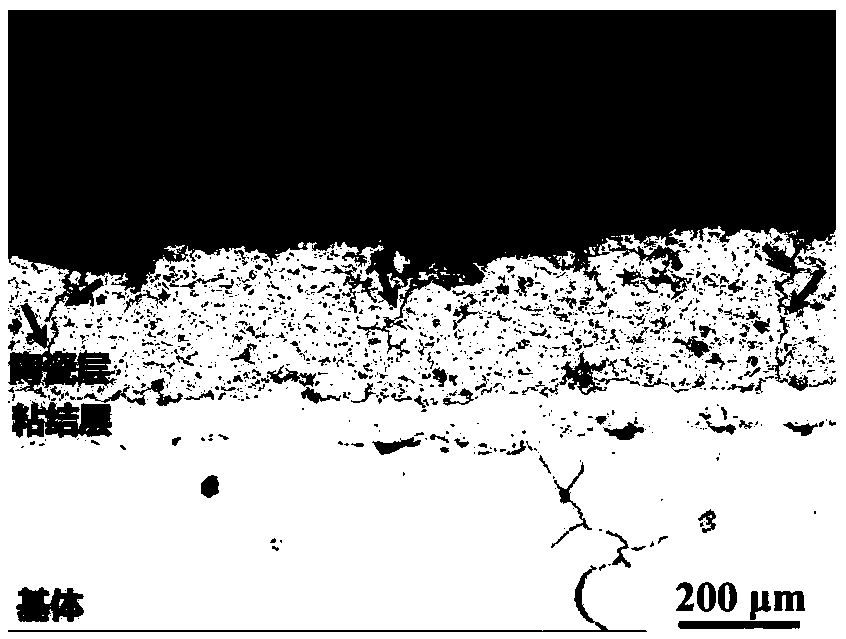

[0047] On the surface of the superalloy substrate and its bonding layer, 8YSZ spraying powder with a particle size of 45 μm to 75 μm was used to prepare a layered ceramic coating with a thickness of 200 μm and an interlayer bonding rate of 28% by spraying with atmospheric plasma technology, such as Picture 1-1 and Figure 1-2 shown. Then the YSZ coating surface is heated by flame, and the coating and the substrate are simultaneously raised to 1200 ° C within 5 minutes. Then adopt a strong current impact with a liquid flow velocity of 20m / s and a liquid flow diameter of 0.5mm to reduce the coating temperature to below 200°C within 10s. During the cooling and shrinking process, the coating is restrained by the matrix and generates transverse tensile stress inside the coating, thereby forming large-scale longitud...

Embodiment 2

[0049] On the surface of the superalloy substrate and its bonding layer, 8YSZ spray powder with a particle size of 45m ~ 75m was used to spray and prepare a layered ceramic coating with a thickness of 200m and an interlayer bonding rate of 28% by atmospheric plasma technology, and then through the flame. The YSZ coating surface is heated, and the coating and the substrate are simultaneously raised to 1350°C within 5 minutes. Then adopt a strong current impact with a liquid flow velocity of 20m / s and a liquid flow diameter of 0.5mm to reduce the coating temperature to below 300°C within 10s. During the cooling and shrinking process, the coating is bound by the matrix to generate transverse tensile stress inside the coating, thereby forming large-scale longitudinal pores.

Embodiment 3

[0051] On the surface of the superalloy substrate and its bonding layer, 8YSZ spray powder with a particle size of 45m ~ 75m was used to spray and prepare a layered ceramic coating with a thickness of 200m and an interlayer bonding rate of 28% by atmospheric plasma technology, and then through the flame. The YSZ coating surface is heated, and the coating and the substrate are simultaneously raised to 900°C within 5 minutes. Then adopt a strong current impact with a liquid flow velocity of 20m / s and a liquid flow diameter of 0.5mm to reduce the coating temperature to below 200°C within 10s. During the cooling and shrinking process, the coating is bound by the matrix to generate transverse tensile stress inside the coating, thereby forming large-scale longitudinal pores.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com