Method for preparing composite carrier by taking modified carbon fiber and polyurethane as raw materials

A composite carrier, polyurethane technology, applied in the direction of being fixed on or in an inorganic carrier, immobilized on/in an organic carrier, etc., can solve the problems in the field of immobilization of few cells, and achieve a favorable immobilization of cells. And multi-batch use, good biocompatibility, improved biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

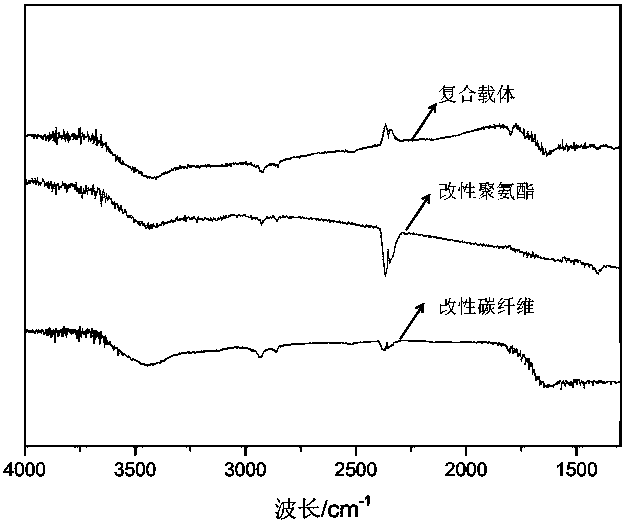

[0025] Preparation of carrier: Add 1g of carbon fiber powder to 200mL, 4% terephthalic acid solution for coating treatment, then add 1g of 0.5cm*0.5cm*0.5cm through 3-methyl-2-oxirane After fully soaking and mixing the methanol-modified polyurethane, ultrasonically disperse it evenly for 24 minutes, and dry it in a blast drying oven for 32-48 minutes. The far-infrared radiator is irradiated for 30 minutes, and the distance is 5-8 cm, and the composite carrier of polyurethane and carbon fiber is obtained.

[0026] Multi-batch fermentation of immobilized cells: Micrococcus luteus was activated and cultured in the seed medium for 20 hours at 30°C, and inoculated with a 6% inoculation amount in the fermentation medium containing a certain amount of carrier, and cultivated for 36 hours. The resulting product is determined by HPLC method, the condition is: chromatographic column: Sugar-Pak TM 1 6.5*300mm column, mobile phase: ultrapure water, flow rate: 1mL / min, temperature: 80°C....

Embodiment 2

[0029] Preparation of the carrier: Add 1.5g of carbon fiber powder to 120mL, 6.3% hexanediol solution for coating treatment, then add 1g of polyurethane modified with glycidol with a size of 0.6cm*0.6cm*0.6cm, fully After soaking, ultrasonically disperse it for 27 minutes to make it evenly dispersed, and dry it in a blast drying oven for 32-48 minutes. 10-1Pa, react in a low-temperature plasma generator with a power of 500W for 35min to obtain a composite carrier of polyurethane and carbon fiber.

[0030] Multi-batch fermentation of immobilized cells: Inoculate α-hemolytic streptococci into the seed medium at an inoculation amount of 2%, culture at 37°C, activate twice, and inoculate the bacterial suspension cultivated for 24 hours into the fermentation medium Among them, the inoculum amount was 4%, and the strain was fermented in multiple batches using a two-stage method. The obtained product was determined by the naphthol-sulfuric acid method, and the detection wavelength w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com