Respiratory bottle for measuring respiratory rate of biofilm, measuring device and measuring method

A technology of respiration rate and biofilm, applied in the field of measuring device and respiration bottle for measuring the respiration rate of biofilm, can solve the problems of interfering with magnetic stirrer, changing mass transfer rate, affecting oxygen mass transfer, etc., to achieve accurate and real growth conditions, The measurement results are accurate and effective, and the effect of avoiding irreversible damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

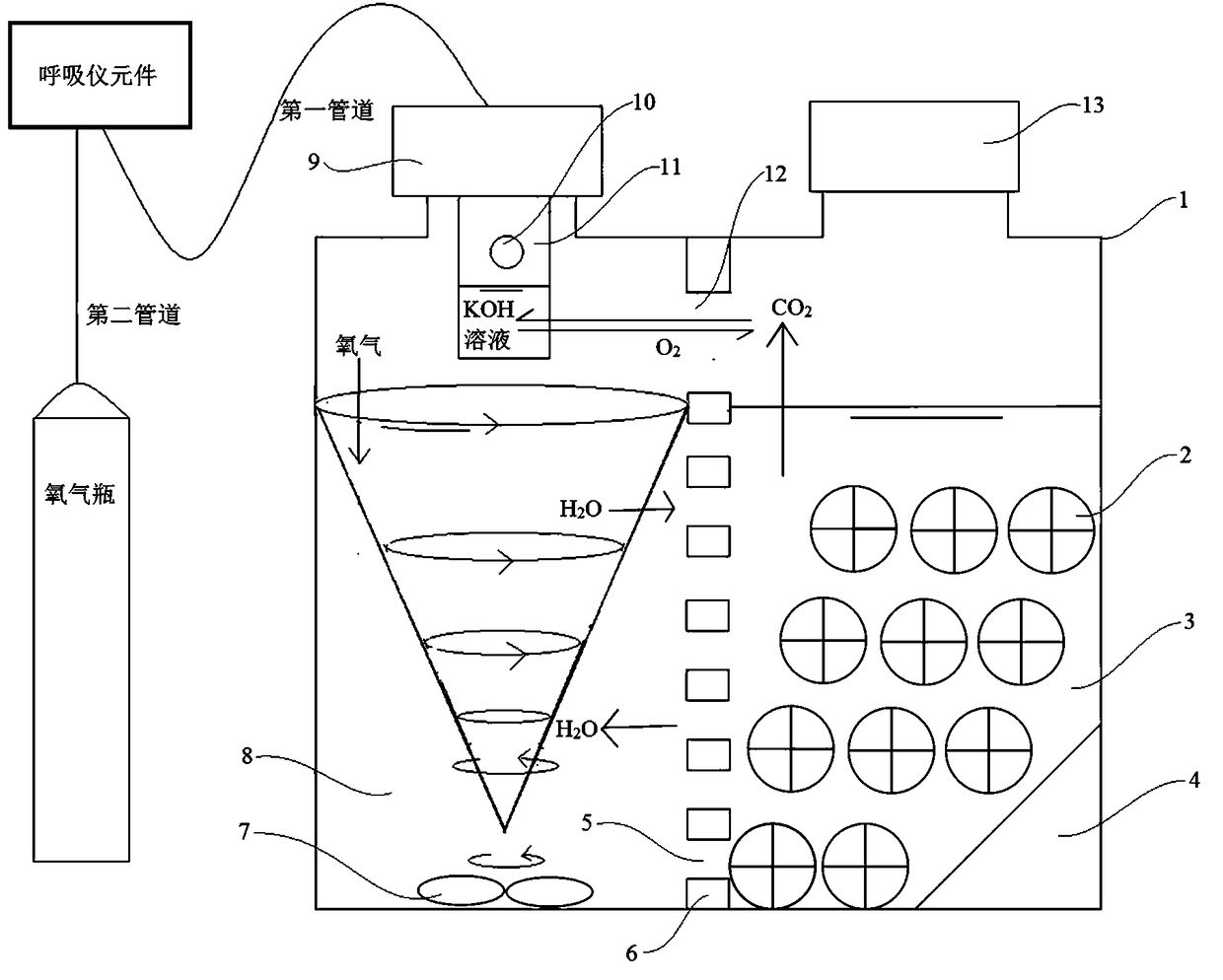

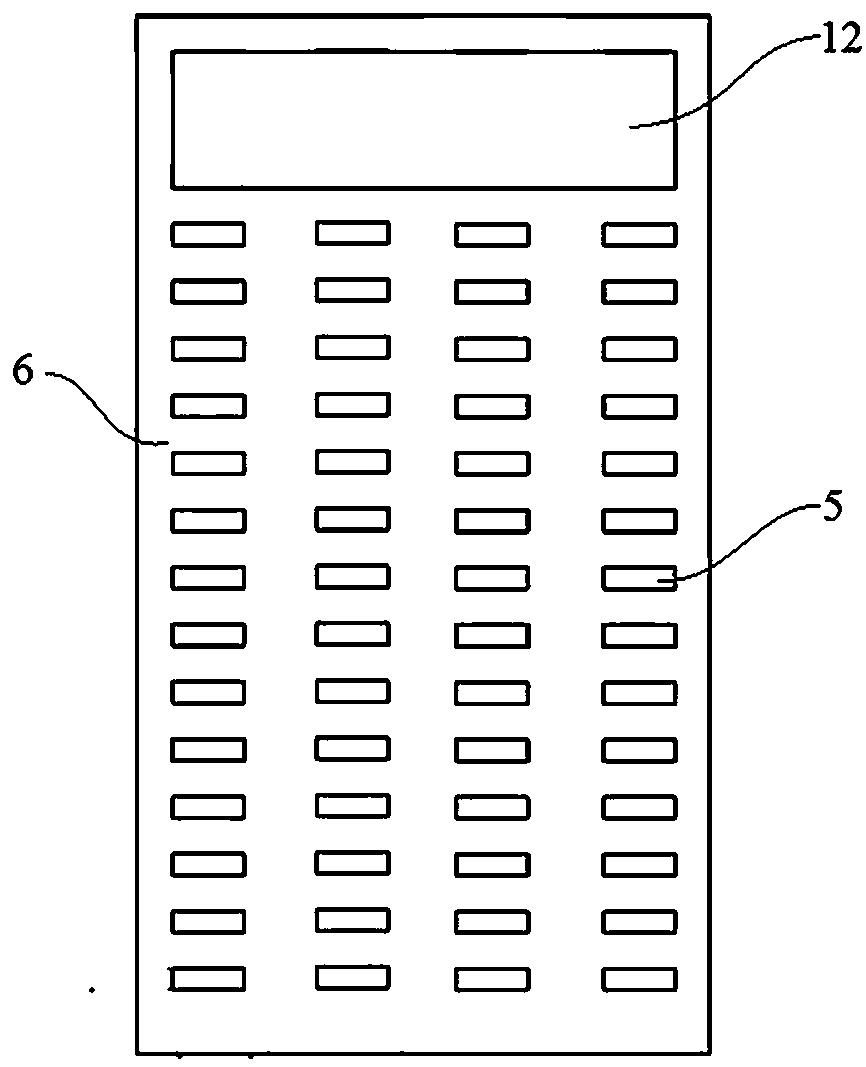

[0037] figure 1 It is the schematic diagram of the respirator composition measuring device that is connected to the breather bottle for measuring the oxygen absorption rate of the embodiment 1 for measuring the biofilm respiration rate, figure 2 It is the top view of the breathing bottle of embodiment 1. Such as Figure 1-2 Shown, a kind of breathing bottle that is used for measuring biofilm respiration rate of the present invention comprises bottle body 1, carbon dioxide absorption tube 11 and the perforated partition 6 that is arranged on bottle body 1 inside; Divided into an oxygen mass transfer stirring zone 8 and a biofilm reaction zone 3, the oxygen mass transfer stirring zone 8 is provided with a stirring device 7, and the biofilm reaction zone 3 is used to place MBBR filler 2; the carbon dioxide absorption pipe 11 is provided with a vent hole 10 and contains Capable of absorbing CO 2 KOH solution to absorb CO in bottle 1 2 The perforated partition 6 has a first ho...

Embodiment 2

[0047] Figure 4 The schematic diagram of the respirator composition measuring device for measuring the oxygen absorption rate connected to the breathing bottle for measuring the biofilm respiration rate of embodiment 2 and embodiment 3, Figure 5 It is the top view of the breathing bottle of embodiment 2. This embodiment is the second embodiment of the breathing bottle of the present invention, as Figure 4-5 As shown, the difference from Example 1 is: the bottle body 1 in this embodiment is a cylinder; the perforated partition 6 is cylindrical, and the inside of the cylindrical perforated partition 6 is an oxygen mass transfer stirring zone 8, and the cylinder Between the outside of the shaped perforated partition 6 and the bottle body 1 is the biofilm reaction zone 3; the perforated partition 6 is located in the middle of the bottle body 1, and the first bottleneck corresponds to the oxygen mass transfer stirring zone inside the cylindrical perforated partition 8. The bot...

Embodiment 3

[0050] Figure 4 The schematic diagram of the respirator composition measuring device for measuring the oxygen absorption rate connected to the breathing bottle for measuring the biofilm respiration rate of embodiment 2 and embodiment 3, Image 6 It is the top view of the breathing bottle of embodiment 3. This embodiment is the second embodiment of the breathing bottle of the present invention, as Figure 4 with Image 6 As shown, the difference from Example 1 is that there are two perforated partitions 6, an oxygen mass transfer stirring zone 8 between the two perforated partitions 6, and a biofilm between the perforated partition 6 and the bottle body 1. Reaction zone 3; bottle body 1 is provided with two second bottlenecks, and described two second bottlenecks correspond to two biofilm reaction zones 3 respectively; Described two second bottlenecks are respectively provided with the seal that is used for sealing bottle cap13.

[0051] The CO released by the microbial re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com