Pentamethylenediamine suberate and its crystals

A technology of pentamethylenediamine suberate and suberic acid, which is applied in the field of crystallization of bio-based material monomers, can solve the problems of inconvenient transportation and use, affecting the purity of pentamethylenediamine itself, and achieve convenient storage and transportation, and improve The effect of improving operability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

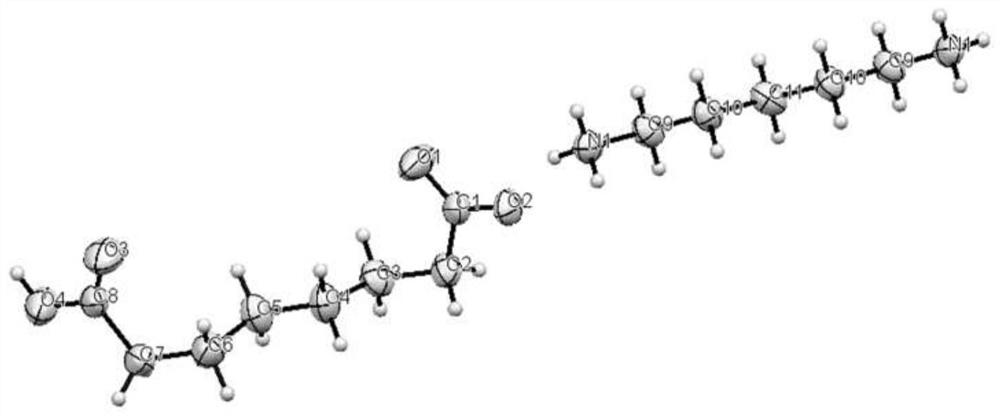

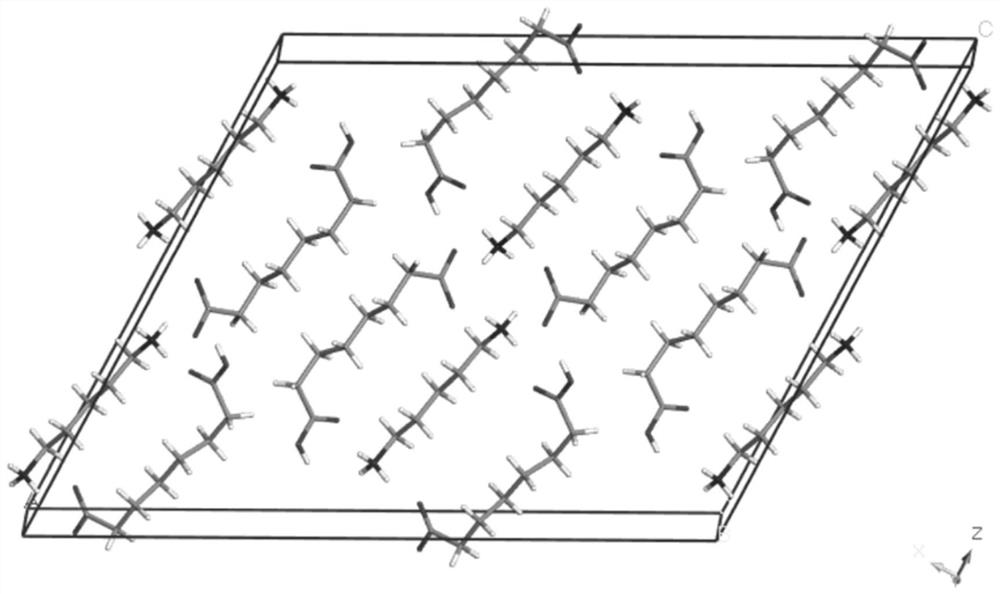

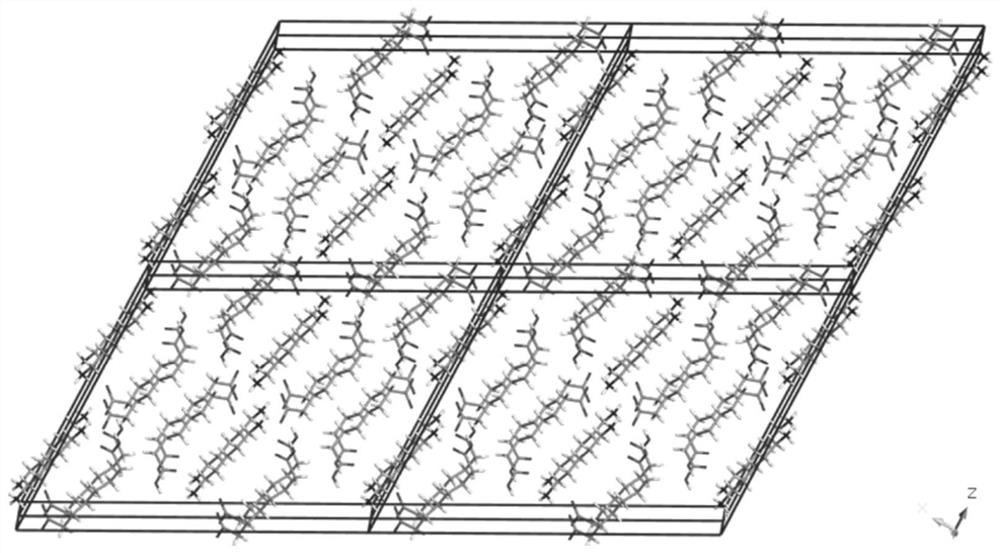

Embodiment 1

[0074] Add 15.00 g of pentamethylenediamine into 100 mL of 95% aqueous ethanol (volume fraction of ethanol is 95%), and stir well to form an aqueous solution of pentamethylenediamine in ethanol. Add 27.00g of suberic acid solid into 350mL of absolute ethanol aqueous solution to form an ethanol solution of suberic acid, then mix the two in a 500mL crystallizer, control the temperature at 25°C, stir for 48h, a white crystal substance appears, and then tank, and carry out solid-liquid separation by means of suction filtration, wash the solid with 150mL of 95% ethanol, and then blow dry the solid for 3 hours, and maintain the temperature at 60-80°C to obtain the crystalline powder of pentamethylenediamine suberate, the crystal structure of which is as follows: figure 2 , image 3 As shown, detailed crystallographic data such as Figure 8 As shown, the crystal structure is C 13 h 28 N 2 o 4 , monoclinic system, C2 / c space group, α=90.00°, β=117.673(4)°, γ=90.00°, unit cell ...

Embodiment 2

[0076] Add 30.00 g of pentamethylenediamine into 100 g of methanol, and stir well to form a pentamethylenediamine methanol solution. Put 51.15g of suberic acid in 500g of methanol, drop it into the methanol solution of pentamethylenediamine at a flow rate of 2mL / min at 25°C, carry out crystallization under stirring, and monitor the pH changes in the process, at about pH 11.0 , add 0.15g of seed crystals, suspend feeding, after crystal growth for 3 hours, drop suberic acid methanol solution into the crystallization system at a flow rate of 0.5mL / min, continue stirring for 2 hours after the feeding is complete, put it into the tank, and pump Carry out the solid-liquid separation of the crystal paddle by filtration, then wash with 80-100mL ethanol, and then vacuum-dry at 45°C for 8h to obtain pentamethylenediamine suberate crystalline powder, whose powder X-ray diffraction pattern is basically as follows: Figure 4 shown. When it is prepared as an aqueous solution with a mass fr...

Embodiment 3

[0078]Dissolve 50.00g of suberic acid in 500g of isopropanol to form a uniform solution of suberic acid in isopropanol, and then transfer it into a 1000mL crystallizer. 35.00 g of pentamethylenediamine was dissolved in 300 mL of 95% acetone water (acetone accounted for 95% by volume) solution to form pentamethylenediamine acetone aqueous solution. Then with the pump, the aqueous solution of pentamethylenediamine acetone is dripped in the isopropanol solution of suberic acid in the mode of 2mL / min, when the amount of the substance of pentamethylenediamine added is 15% of the amount of substance of suberic acid, add 0.3g seed crystal, add the remaining pentamethylenediamine acetone aqueous solution at 0.2mL / min, the whole process is carried out under stirring, the rotation speed is controlled at 250-400rpm, and the temperature is controlled at 15°C. When the feeding is completed, the crystallization is completed, and the tank for solid-liquid separation, and then wash the filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com