Method for sintering pzt piezoelectric ceramics at low temperature and piezoelectric ceramics

A low-temperature sintering technology for piezoelectric ceramics, applied in the field of piezoelectric ceramics and its preparation, can solve the problems of low-temperature sintering piezoelectric performance deterioration, high sintering temperature, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

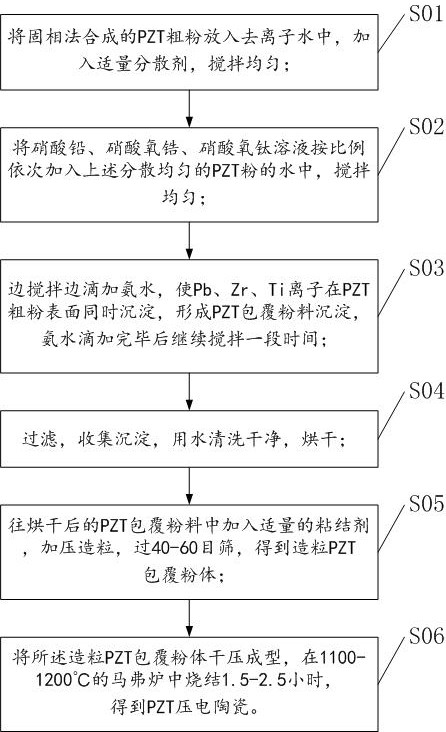

Method used

Image

Examples

Embodiment 1

[0044]Example 1 Add 10% coprecipitation method to synthesize the PZT mixed powder of the powder

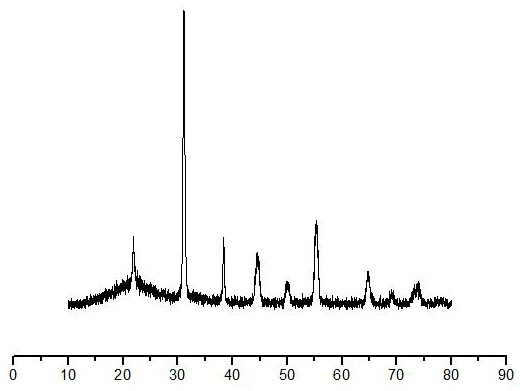

[0045]A sintering method of PZT piezoelectric ceramic, first, the PZT coarse powder synthesized by the solid phase method is placed in deionized water, and a polyethylene glycol comprising the piezoelectric ceramic weight is added, and the PZT powder is dispersed in water. Honestylene; lead, zirconium nitrate, nitrate zirconium, nitrate oxy-nitrate, and the above-mentioned PZT powder, the addition ratio of the three solutions should cause the proportion of lead, zirconium, titanium ions in the solution and PZT The proportion of lead, zirconium and titanium in the coarse powder is consistent, and the addition of the solution is added in accordance with the proportion of the PZT fine powder obtained for the PZT coarse powder, and the agitation is continued to uniformly dispersion. A ammonia water was added dropwise at 15 ml / min at a rate of 15 ml / min, and Pb, Zr, Ti ions were simultaneou...

Embodiment 2

[0047]Example 2 Add 30% coprecipitation method to synthesize the PZT mixed powder of the powder

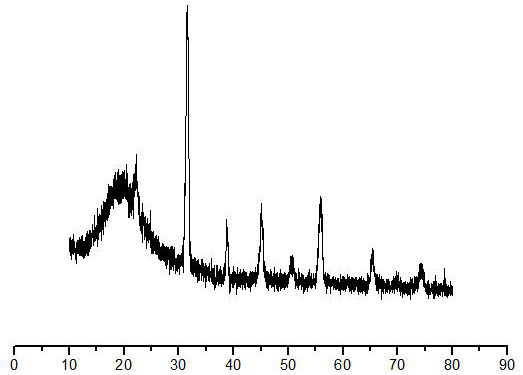

[0048]A sintering method of PZT piezoelectric ceramic, first, the PZT coarse powder synthesized by the solid phase method is placed in deionized water, and a polyethylene glycerol comprising the piezoelectric ceramic weight of 1%, stirred, and the PZT powder is in the water. Uniform dispersion; then lead the nitrate, nitrate zirconium, nitrate oxitate solution, and the proportion of the addition ratio of the three solutions, the proportion of lead, zirconium and titanium ions in the solution should be added. The proportion of lead, zirconium, titanium in PZT coarse powder is consistent, and the addition of the solution is added in accordance with the proportion of 30% of the PZT fine powder obtained for the PZT coarse powder, and continues to stir the dispersion. A ammonia water was added dropwise at 15 ml / min at a rate of 15 ml / min, and Pb, Zr, Ti ions were simultaneously precipitated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com