Ultrahigh performance cement-based erosion and abrasion resistant material

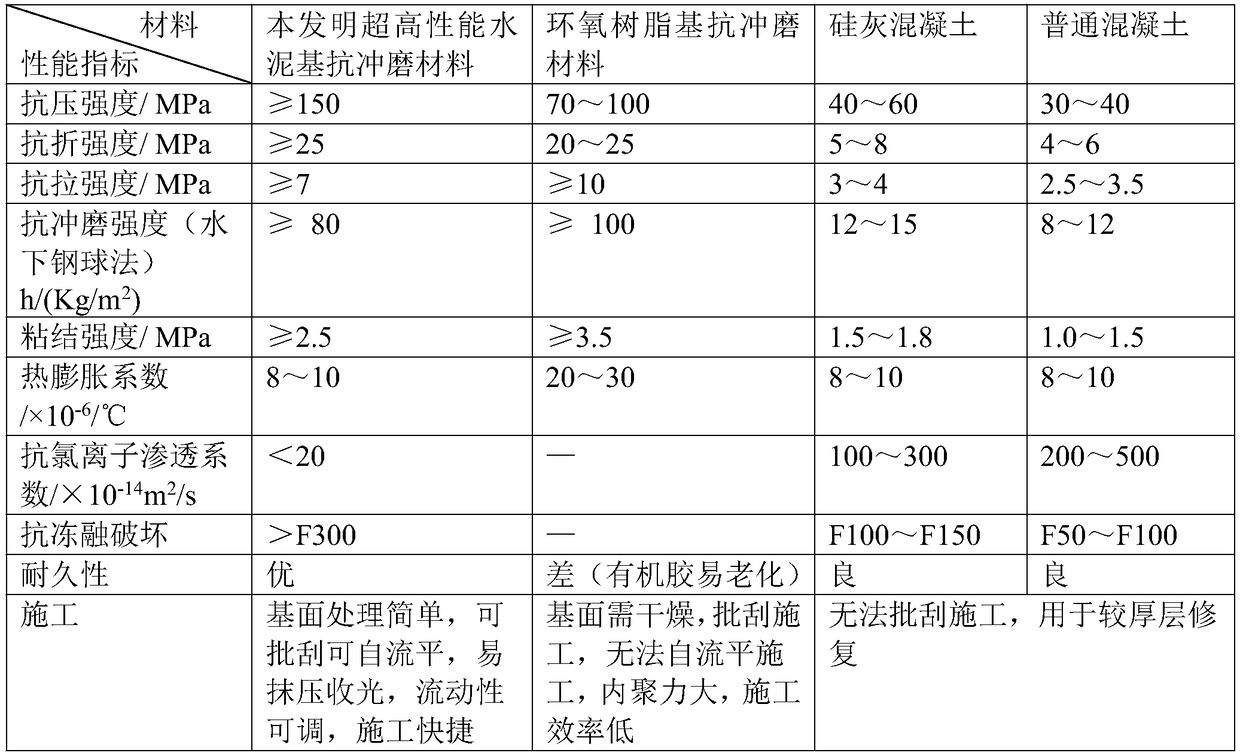

An ultra-high-performance, cement-based technology, applied in the field of ultra-high-performance cement-based anti-abrasion materials and anti-abrasion materials, can solve the problems of unstable anti-abrasion materials, insufficient anti-abrasion strength, and high application cost, and achieve The effect of reducing the number of macroscopic defects, reducing mechanical strength, and improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] An ultra-high-performance cement-based anti-abrasion material, which is made of the following components by weight: 100 parts of ordinary Portland cement, 25 parts of micro-silica fume, 15 parts of slag superfine powder, 15 parts of microbeads, expansion 10 parts of additive, 170 parts of quartz sand, 20 parts of steel fiber, 4.5 parts of composite admixture, 33 parts of water. The composite admixture is composed of redispersible rubber powder, polycarboxylate water reducer, defoamer, and viscosity modifier in a ratio of 30:20:1:1 by weight.

[0040] Among them, ordinary Portland cement is P O42.5 cement; the content of silica in microsilica fume is 95%, the 28d activity index is 108%, the average particle size is 0.2μm, and the specific surface area is 15㎡ / g; Fine powder is granulated blast furnace slag with 28d activity index of 105%, average particle size of 9μm, and specific surface area of 1.4㎡ / g; microbeads are 28d activity index of 106%, average particle size o...

Embodiment 2

[0043] An ultra-high-performance cement-based anti-abrasion material, which is made of the following components by weight: 100 parts of ordinary Portland cement, 15 parts of micro-silica fume, 20 parts of slag superfine powder, 20 parts of micro-beads, expansion 8 parts of agent, 160 parts of quartz sand, 25 parts of steel fiber, 4 parts of composite admixture, and 35 parts of water. The composite admixture is composed of redispersible rubber powder, polycarboxylate water reducer, defoamer, and viscosity modifier in a weight ratio of 30:20:2:0.5.

[0044] Among them, ordinary Portland cement is P·O42.5 cement; the silica content in microsilica fume is 99%, the 28d activity index is 110%, the average particle size is 0.19μm, and the specific surface area is 18㎡ / g; Fine powder is granulated blast furnace slag with 28d activity index of 105%, average particle size of 10μm, and specific surface area of 1.3㎡ / g; microbeads are 28d activity index of 108%, average particle size of 1...

Embodiment 3

[0047] An ultra-high-performance cement-based anti-abrasion material, which is made of the following components by weight: 100 parts of ordinary Portland cement, 18 parts of micro-silica fume, 12 parts of ultra-fine slag powder, 10 parts of micro-beads, expansion 6 parts of additive, 200 parts of quartz sand, 15 parts of steel fiber, 3.5 parts of composite admixture, 40 parts of water. Among them, the composite admixture is composed of redispersible rubber powder, polycarboxylate water reducer, defoamer, and viscosity regulator in a weight ratio of 30:20:1:2.

[0048] in

[0049] Ordinary Portland cement is P·O42.5 cement; the content of silica in silica fume is 92%, the 28d activity index is 105%, the average particle size is 0.3μm, and the specific surface area is 15㎡ / g; the slag is ultra-fine Powder is granulated blast furnace slag with 28d activity index of 105%, average particle size of 10μm, and specific surface area of 1.2㎡ / g; microbeads are 28d activity index of 105...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power level | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com