Composite phosphorus-free corrosion-scale inhibitor and preparation method thereof

A technology of phosphorus-free corrosion and scale inhibitors, applied in chemical instruments and methods, descaling and water softening, special treatment goals, etc., can solve problems such as nozzle clogging and outer package scaling, and achieve low cost and environmental friendliness , highly targeted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1 Preparation of composite non-phosphorus corrosion and scale inhibitor of the present invention

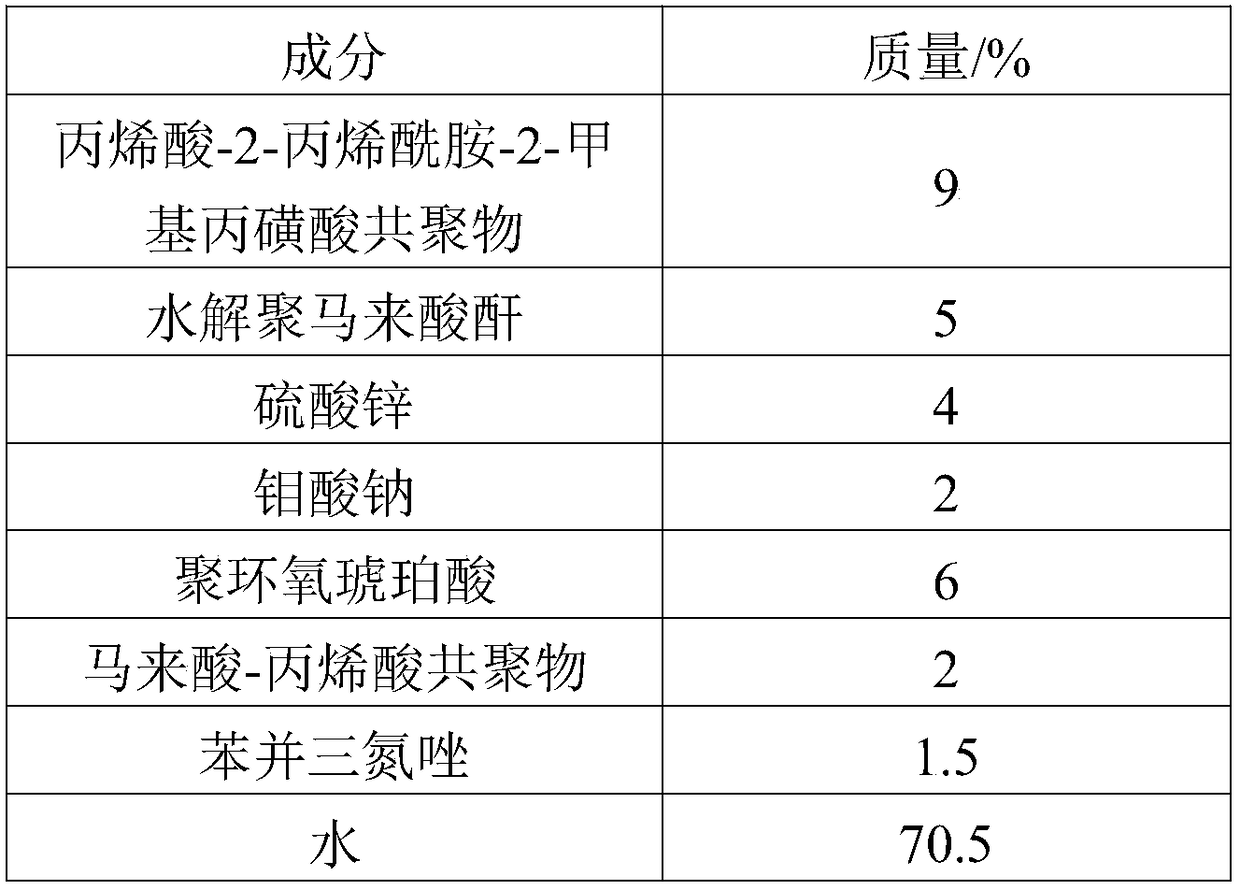

[0030] Raw materials used in this embodiment and their quality are as follows:

[0031] Table 1 Raw material quality table

[0032]

[0033] Among the above-mentioned composite non-phosphorus corrosion and scale inhibitors suitable for industrial circulating water systems, the molecular weight of acrylic acid-2-acrylamide-2-methylpropanesulfonic acid copolymer is 1000-10000 Da, it is an aqueous solution, and its solid content is ≥ 30%; The molecular weight of hydrolyzed polymaleic anhydride is 450-800Da, which is an aqueous solution with a solid content ≥ 48%; sodium molybdate is a white powder with a content greater than 99%; the molecular weight of polyepoxysuccinic acid is 400-800Da, which is an effective The chelate; the molecular weight of maleic acid-acrylic acid copolymer is 300~4000Da.

[0034] Its preparation method is as follows: acrylic acid-2-ac...

Embodiment 2

[0035] Embodiment 2 Preparation of composite non-phosphorus corrosion and scale inhibitor of the present invention

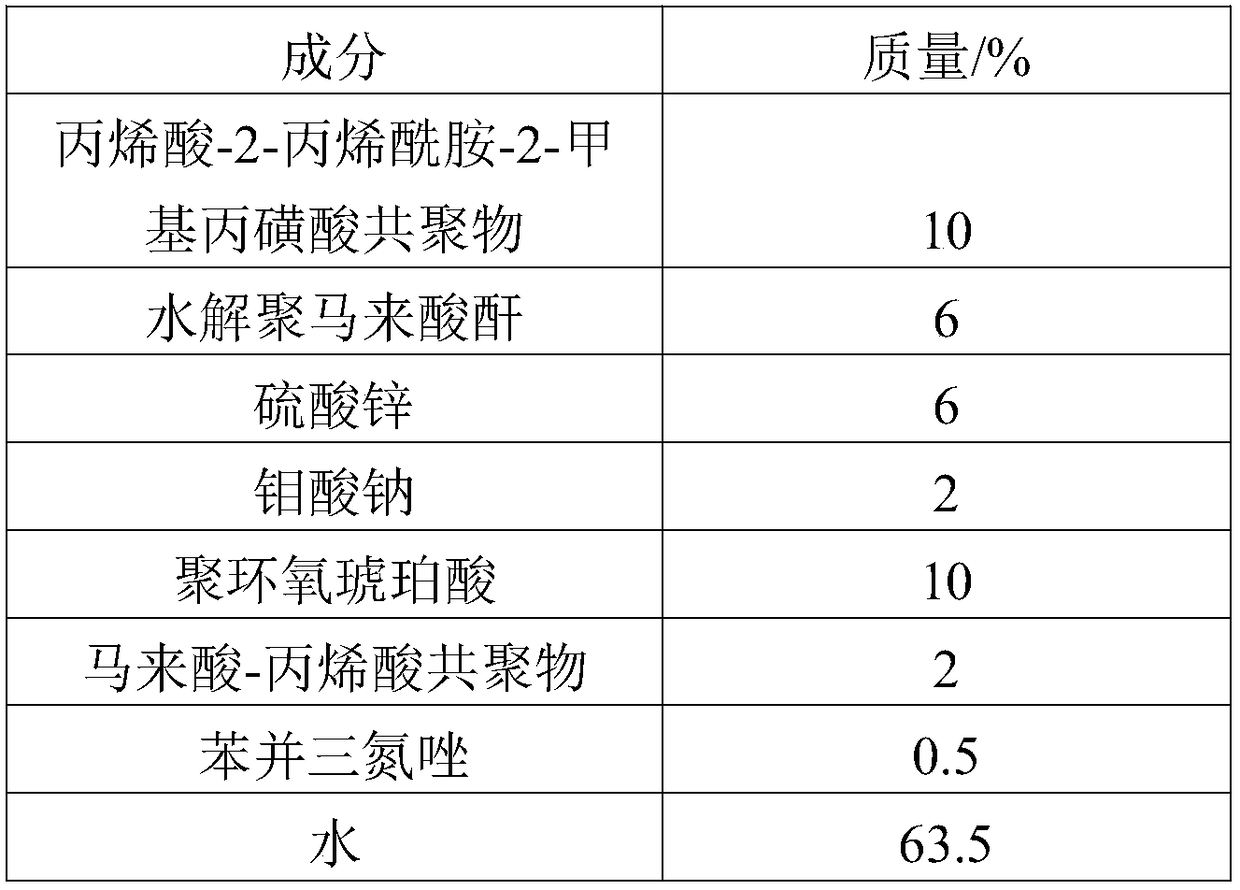

[0036] Raw materials used in this embodiment and their quality are as follows:

[0037] Table 2 Raw material quality table

[0038]

[0039] Above-mentioned raw material is identical with embodiment 1. Its preparation method is identical with embodiment 1.

Embodiment 3

[0040] Example 3 Preparation of composite non-phosphorus corrosion and scale inhibitor of the present invention

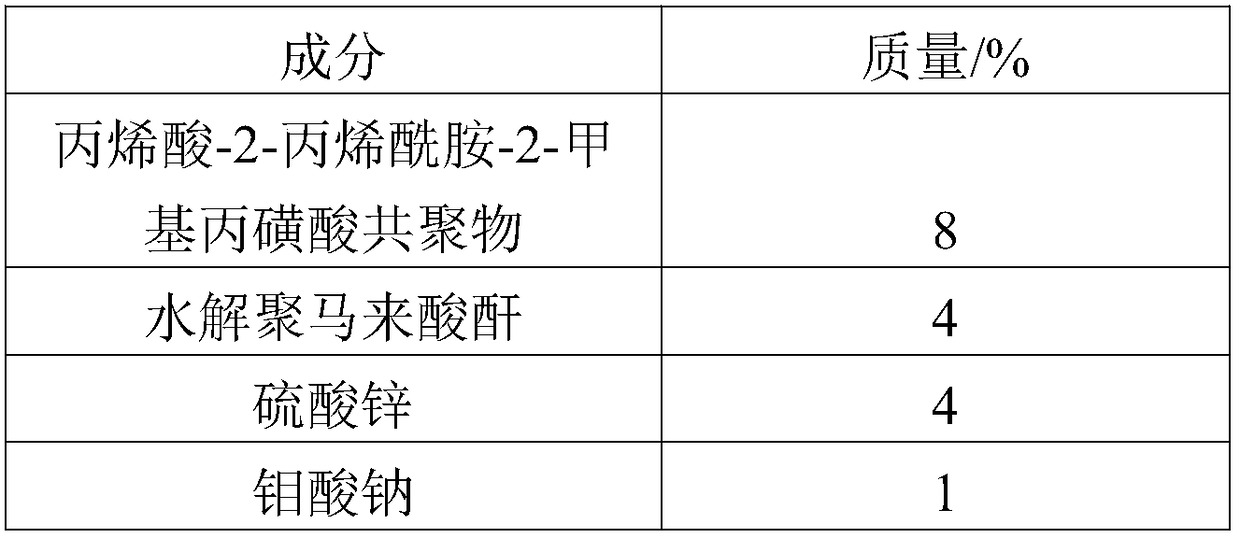

[0041] Raw materials used in this embodiment and their quality are as follows:

[0042] Table 3 raw material quality table

[0043]

[0044]

[0045] Above-mentioned raw material is identical with embodiment 1. Its preparation method is identical with embodiment 1

PUM

| Property | Measurement | Unit |

|---|---|---|

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com