Standard disc for storage and transfer of magnetic tiles

A standard, magnetic tile technology, applied in the field of magnetic tile storage and transfer of standard disks, can solve the problems of messy product placement, reduced product quality, low work efficiency, etc., to meet the needs of large-scale processing and production, stable production and transportation, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] See attached picture.

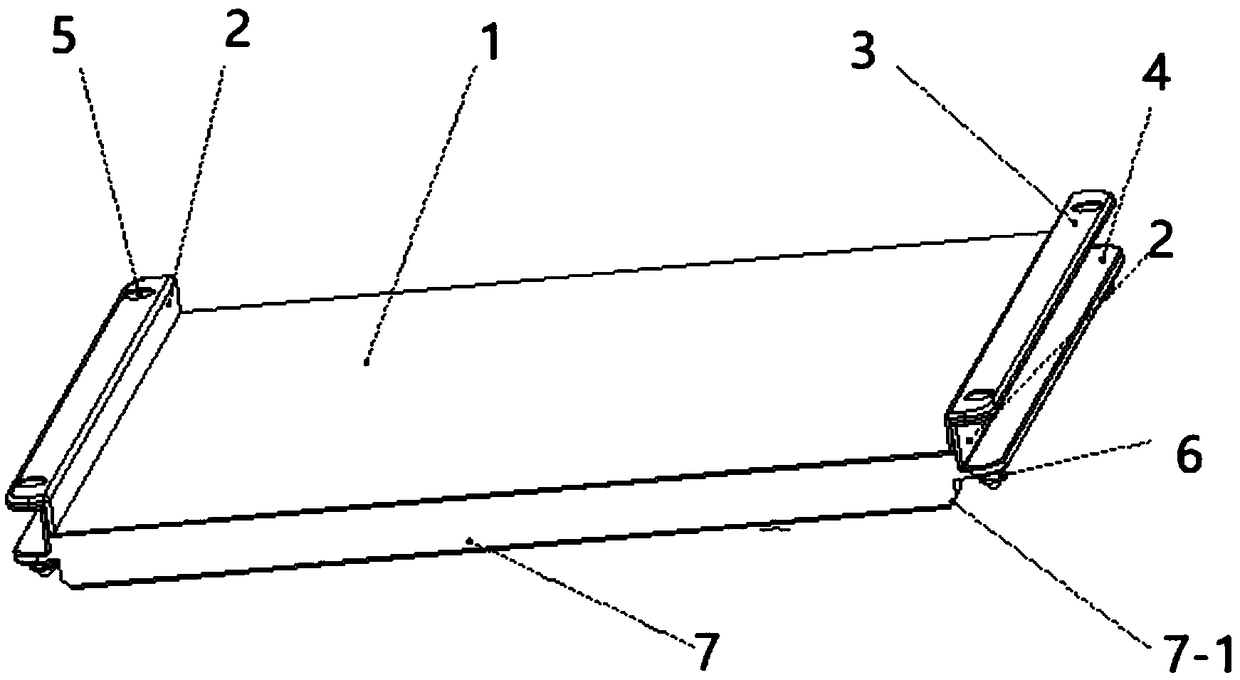

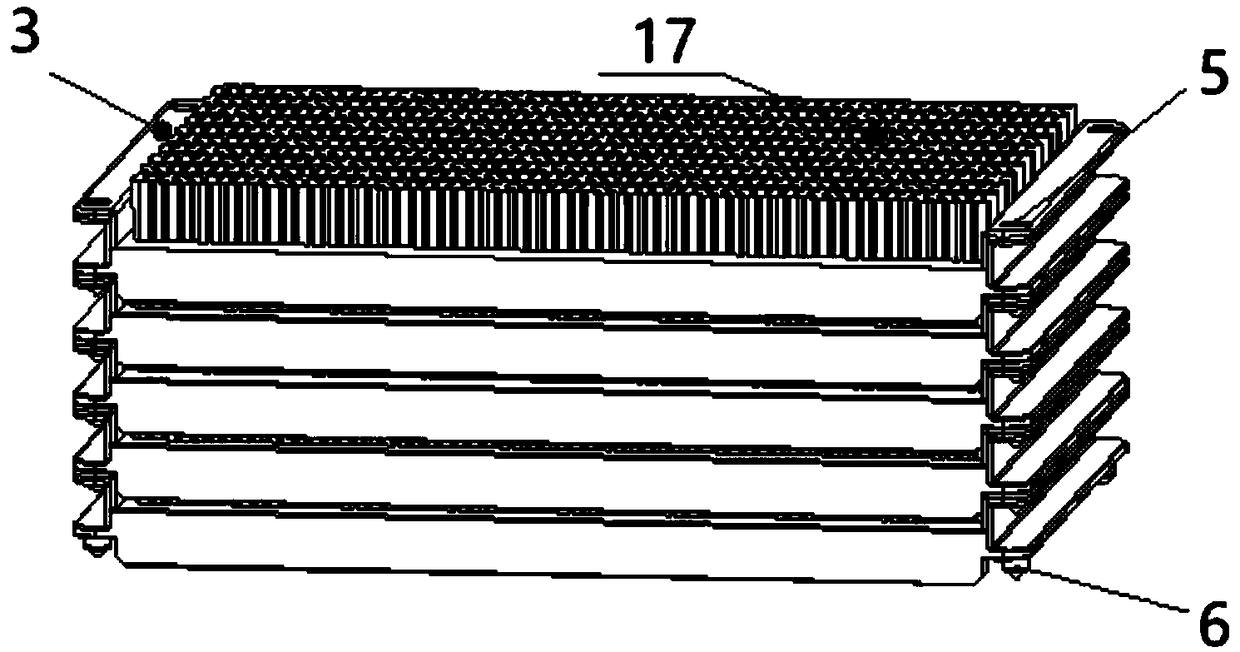

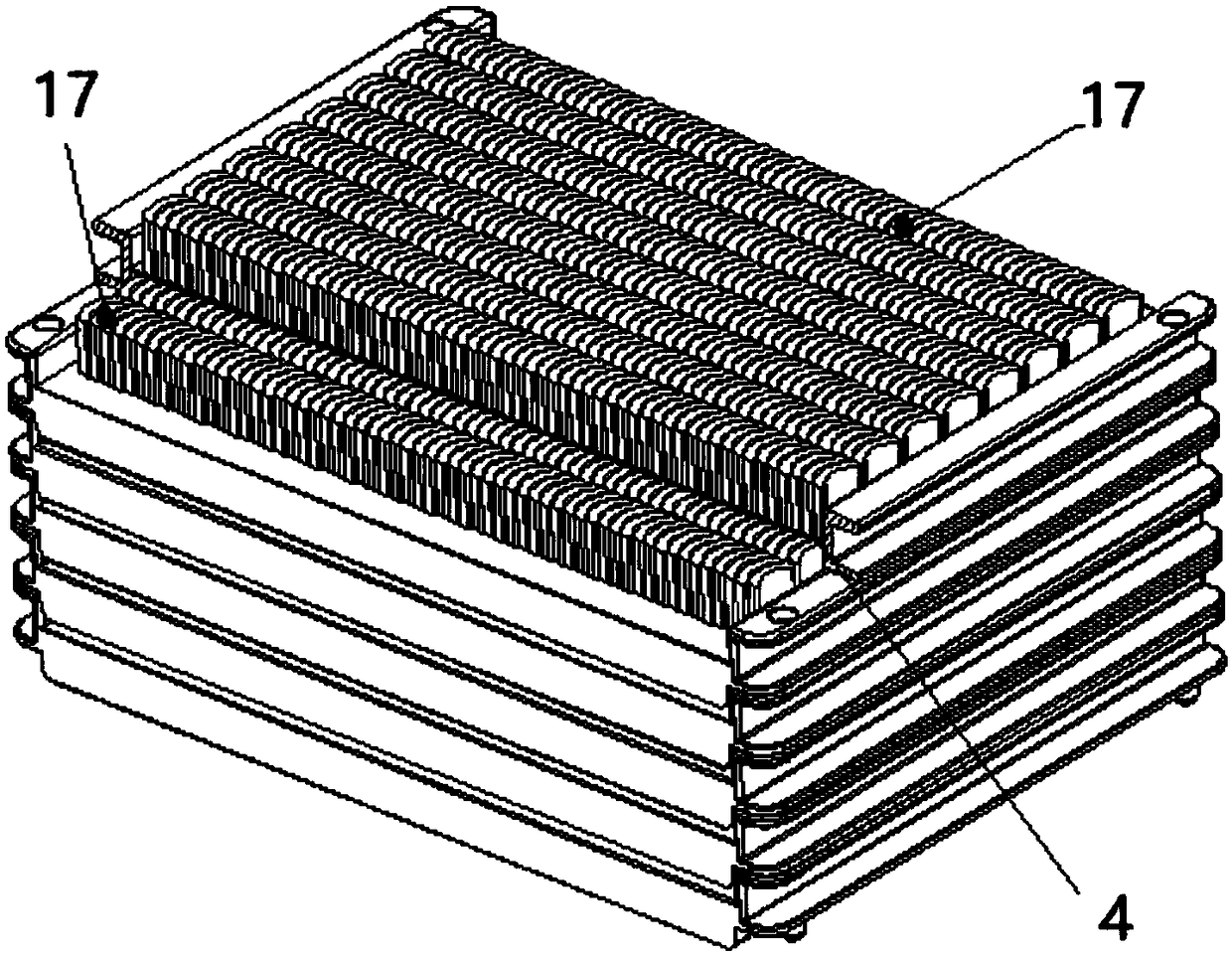

[0025] A magnetic tile storage and transfer standard disk, including a disk body 1, characterized in that: the two ends of the disk body 1 are respectively provided with a disk head assembly, and the disk head assembly includes an end plate 2 respectively, and the end plate The upper and lower ends of 2 are respectively provided with an upper plate bearing edge 3 and a lower plate bearing edge 4, and the upper plate bearing edge 3 and the lower plate bearing edge 4 are arranged at intervals correspondingly up and down, and the upper plate bearing edge 3 is provided with an upper plate positioning Hole 5, the lower plate positioning pin 6 is provided on the bottom end surface of the lower plate bearing side 4, the position of the upper plate positioning hole 5 and the lower plate positioning pin 6 correspond to each other and can be buckled correspondingly, the plate body 1 Both sides of the bottom end surface of the bottom are respectively provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com