Vehicle body skirt plate structure for rail traffic vehicle and shaping method thereof

A rail transit vehicle and forming method technology, applied in the field of rail transit vehicle body skirt plate structure and its forming, can solve problems such as not being able to meet the needs of high-speed passenger cars, and achieve good rigidity, small internal stress, and good thermal expansion matching performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

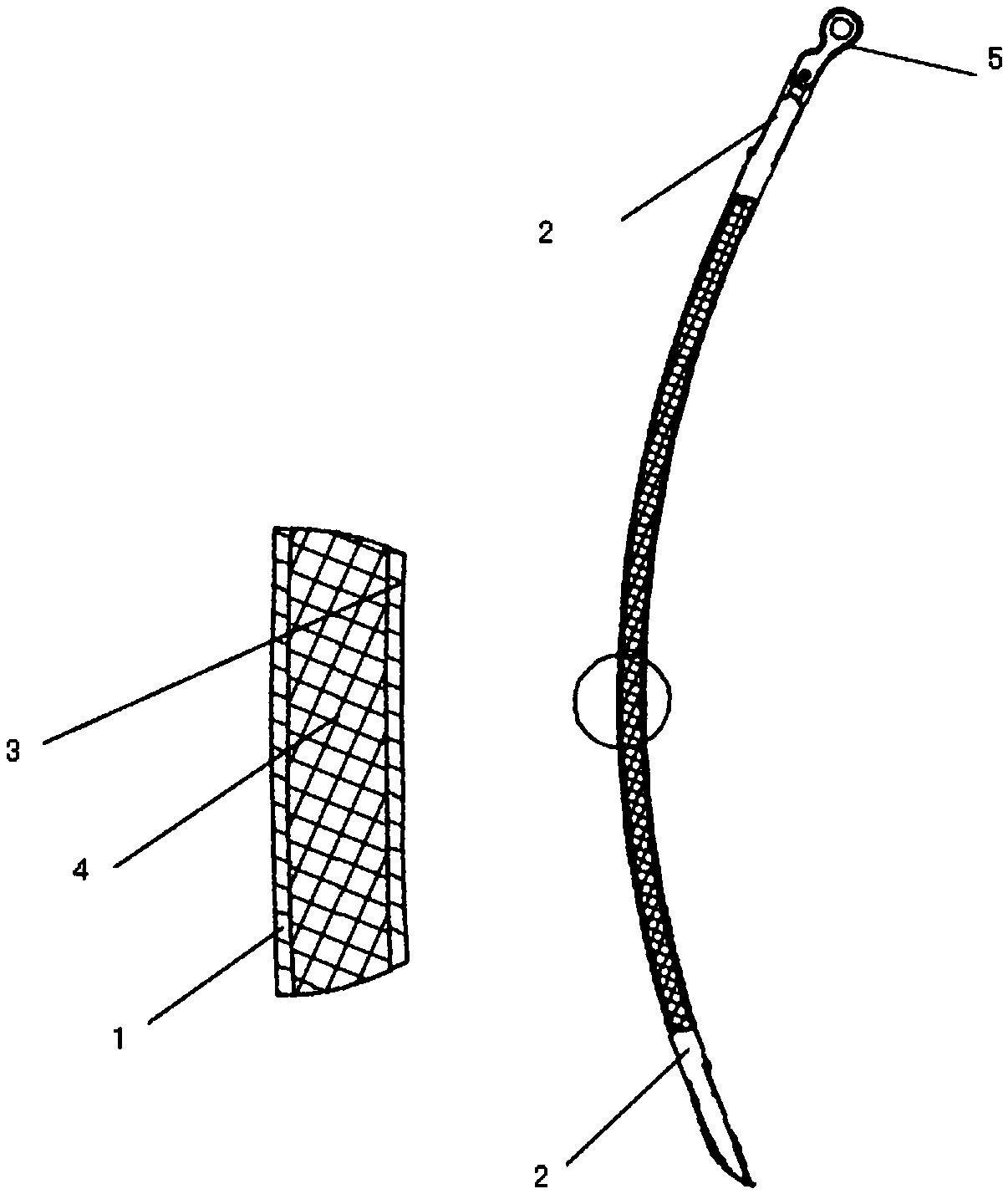

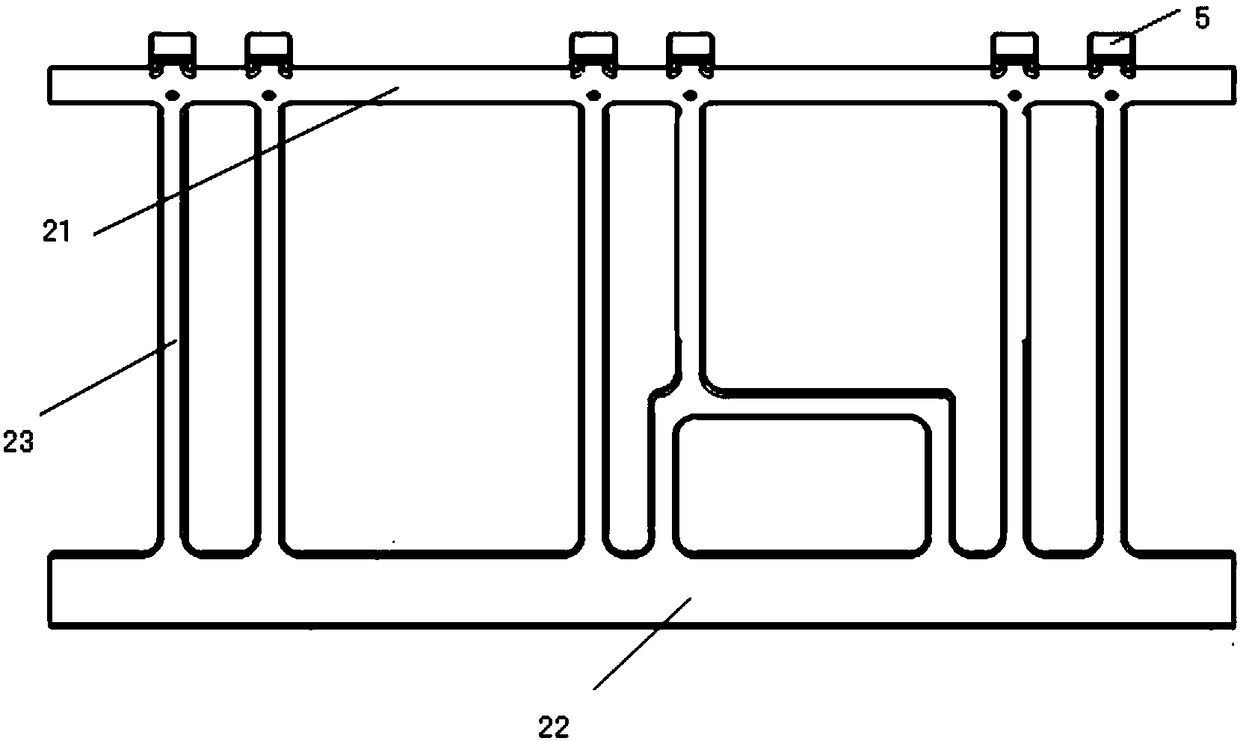

[0040] see figure 1 with 2 , the embodiment of the present invention provides a rail transit vehicle body skirt structure, including an outer panel 1, a load-bearing frame 2, an inner panel 3 and a honeycomb core 4, such as image 3 As shown, the load-bearing frame 2 includes an upper end frame 21, a lower end frame 22 and a reinforcing rib 23 arranged between the upper end frame 21 and the lower end frame 22, and the load-bearing frame 2 is covered by a fiber-reinforced resin-based composite material in a foam. The outer panel 1 and the inner panel 3 are both made of fiber-reinforced resin-based composite materials, and the load-bearing frame 2, outer panel 1 and inner panel 3 are stacked and fixedly connected in sequence, as image 3 As shown, the load-bearing frame 2 divides the interlayer b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com